Puncture clamp for ground potential live working of insulated wire line connection

A line connection and insulated wire technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of difficult stripping, unfavorable safe operation of wires, and low precision, so as to solve the problem of waterproof sealing and quickly overlap branch lines , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

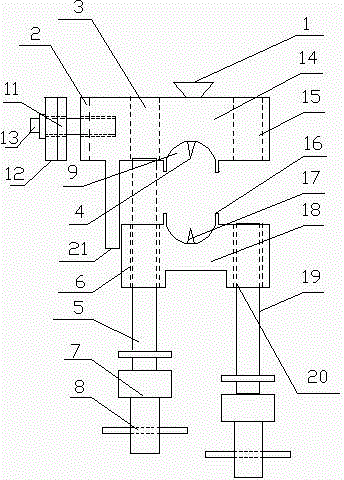

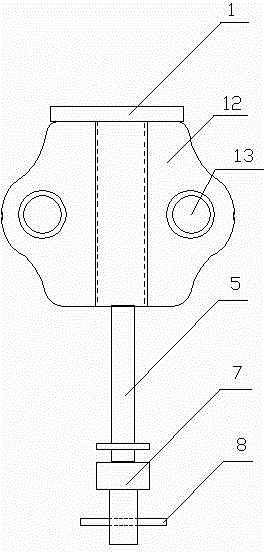

[0012] A puncture clamp for ground potential live work connected with insulated wires, comprising an upper body of the clamp and a lower body of the clamp matched with the upper body of the clamp. There are upper piercing teeth in the main wire slot, and wire limit slots opposite to the main wire slot are arranged on the lower body of the wire clip. There are a first screw hole and a second screw hole, the lower body of the clamp is provided with a first fastening hole and a second fastening hole corresponding to the first screw hole and the second screw hole, the first fastening bolt, the second The fastening bolts pass through the first fastening hole and the second fastening hole respectively to connect with the first screw hole and the second screw hole, so as to realize the cohesion between the upper body of the wire clamp and the lower body of the wire clamp. The barbed teeth puncture the outer skin of the main line to achieve good contact with the metal part of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com