Flow field structure of AC excited variable speed generator

A technology of AC excitation and generator, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of generator output current, power oscillation, unstable operation, etc., achieve reduced ventilation loss, reasonable distribution, and increased effective height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

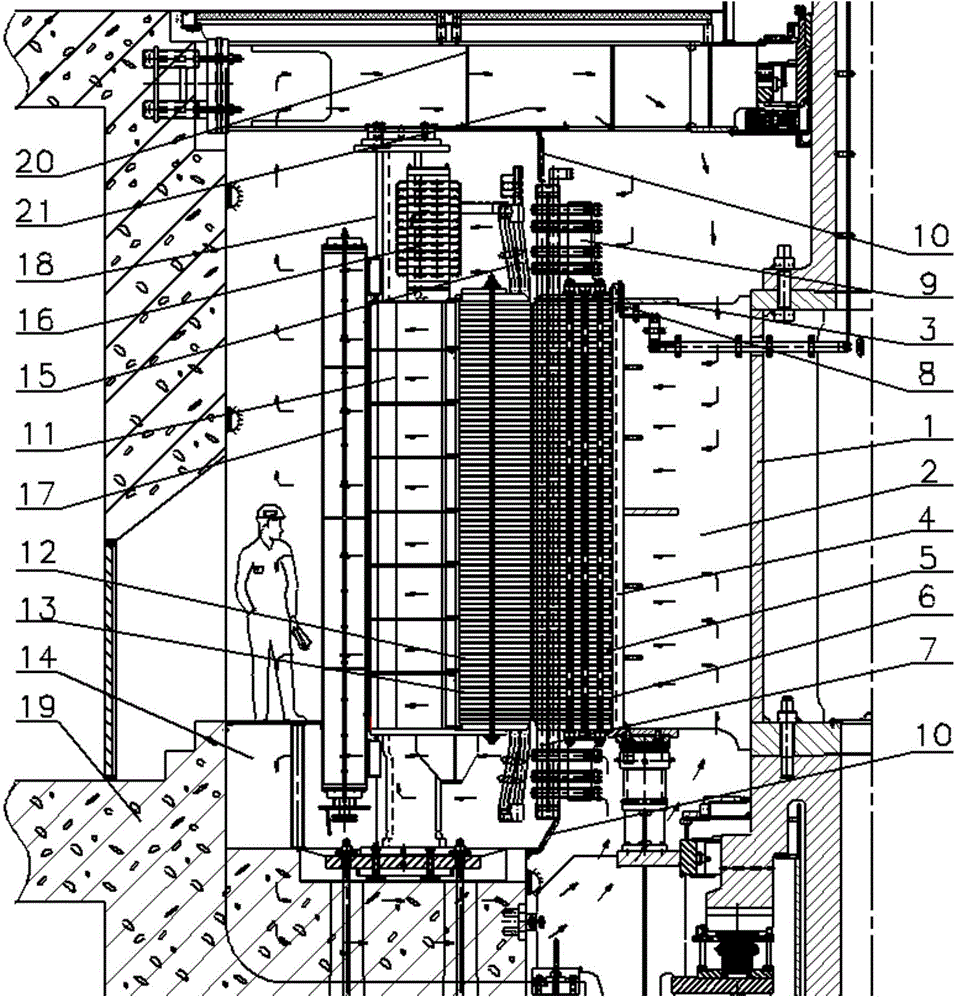

[0012] Such as figure 1 As shown, the flow field structure of an AC excitation variable speed generator consists of a rotor center body 1, a rotor bracket 2, a bracket enclosure 3, a bracket L rib 4, a rotor core 5, a rotor ventilation ditch 6, a rotor coil 7, and a rotor core Pressure plate 8, rotor end coil support 9, windshield 10, stator base 11, stator core 12, stator ventilation ditch 13, lower air duct 14, stator coil 15, collector ring 16, cooler 17, vertical rib ring plate 18. The foundation 19, the upper frame 20 and the upper air duct 21, wherein the rotor bracket 2 is welded on the rotor center body 1, the bracket shroud 3 is welded on the axial side surface of the rotor bracket 2, and the bracket L rib 4 is welded on the rotor On the outer surface of the bracket 2, the rotor core 5 and the rotor ventilation ditch 6 are arranged alternately in the axial direction, and the inner circle is provided with dovetail grooves. The rotor core 5, the rotor ventilation ditch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com