Pressure cleaning method of full automatic soybean milk machine

A soymilk machine, fully automatic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problem of difficult cleaning of soymilk machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

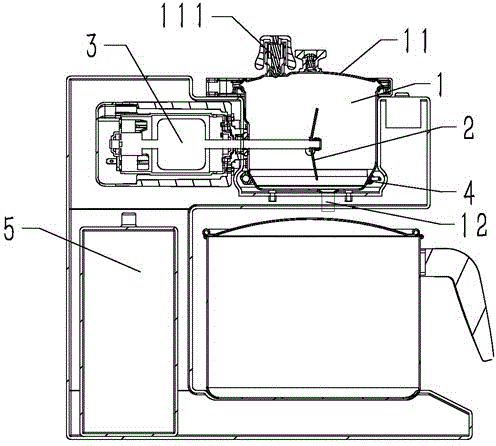

[0025] Such as figure 1 As shown, the fully automatic soymilk machine involved in the present invention includes a small space grinder 1, a cutter 2, a motor 3, a heating device 4, a water supply mechanism 5, a chamber cover 11 and a circuit control unit, and the motor 3 drives the cutter in the small space grinder 1. Internal rotation, the heating device 4 heats the material in the small space pulverizer 1, the water supply mechanism 5 supplies water to the small space pulverizer, the chamber cover 11 is fastened on the small space pulverizer 1 and is provided with a pressure relief valve 111, the small space A slurry discharge valve 12 is provided on the space pulverizer. Wherein, the volume of the small space pulverizer is 50-1000 milliliters.

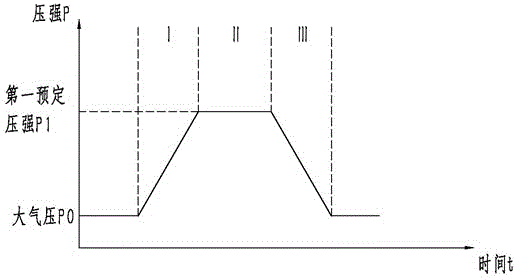

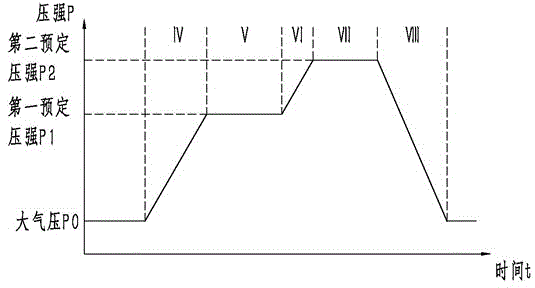

[0026] The pressure cleaning method for the above-mentioned automatic soybean milk machine at least includes the following steps in sequence:

[0027] (1) Water intake stage: open the pressure relief valve, the water supply mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com