Wet electrostatic precipitator, desulfurization system as well as desulfurization and dust removal process

A technology of wet electrostatic precipitator and demisting device, which is applied in combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of inconvenient installation, inconvenient maintenance and replacement, damage to circulating pump and post-processing system, etc. The effect of easy installation and disassembly and maintenance, saving maintenance difficulty and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

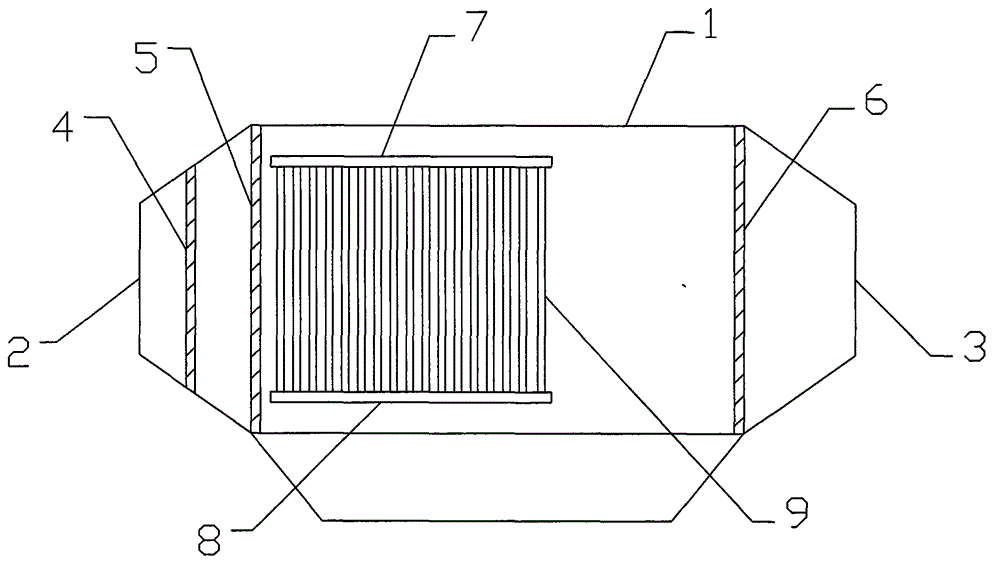

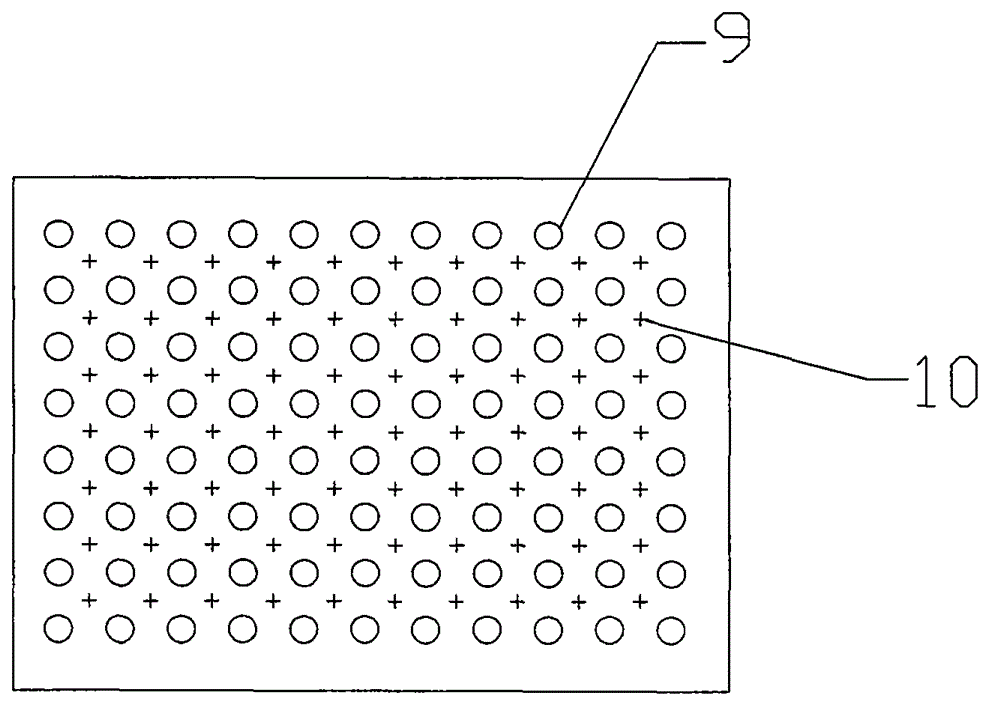

[0027] A desulfurization system used in the desulfurization industry described in the embodiment of the present invention is provided with a device for dedusting the exhausted waste gas in the system, and the device adopts a wet electrostatic precipitator. The use of the wet electrostatic precipitator is different from the traditional dust removal method. The wet electrostatic precipitator needs to be placed horizontally in the entire desulfurization system to replace the traditional vertical desulfurization tower design. like figure 1 and figure 2 As shown, the wet electrostatic precipitator includes a cylindrical dust removal box 1 placed horizontally and having an air inlet 2 and an air outlet 3. The air inlet of the dust removal box is connected to the exhaust gas discharge port in the desulfurization system. The air outlet of the box body is connected to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com