A method for thermally dismantling roll rings of horizontal rolls in a rolling mill

A technology of horizontal rolls and roll rings, which is applied in the field of rolling mill machinery and equipment, can solve the problems of polluting the environment, difficult separation of roll rings and roll shafts, and low separation efficiency of roll rings and roll shafts, so as to improve the environment and shorten the thermal disassembly time, less pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

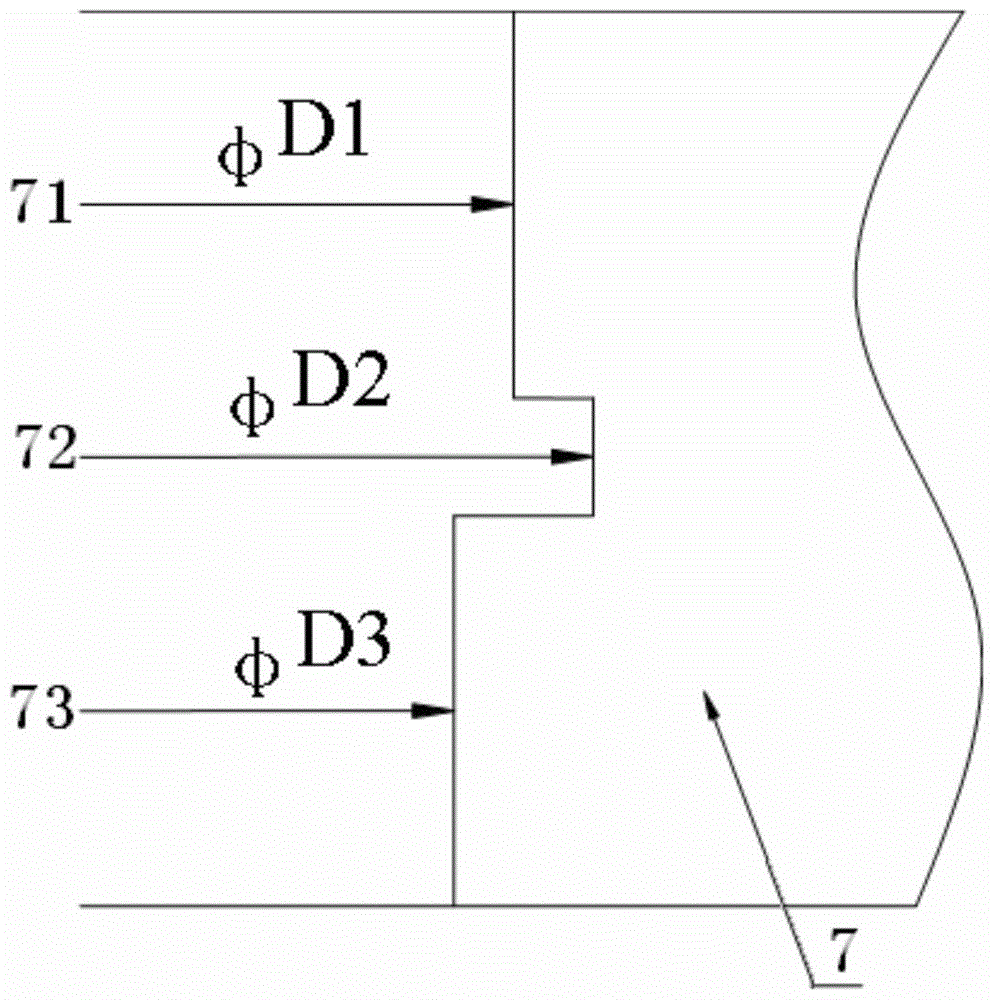

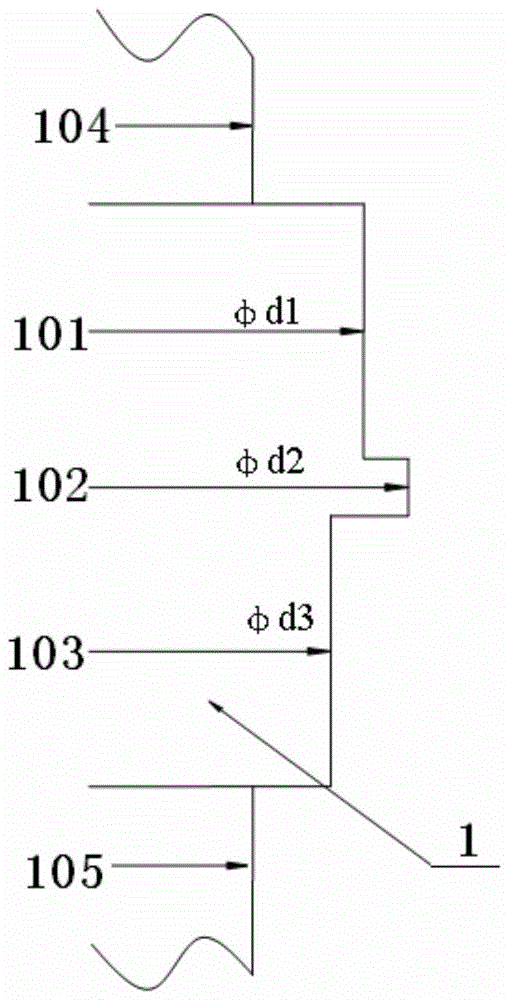

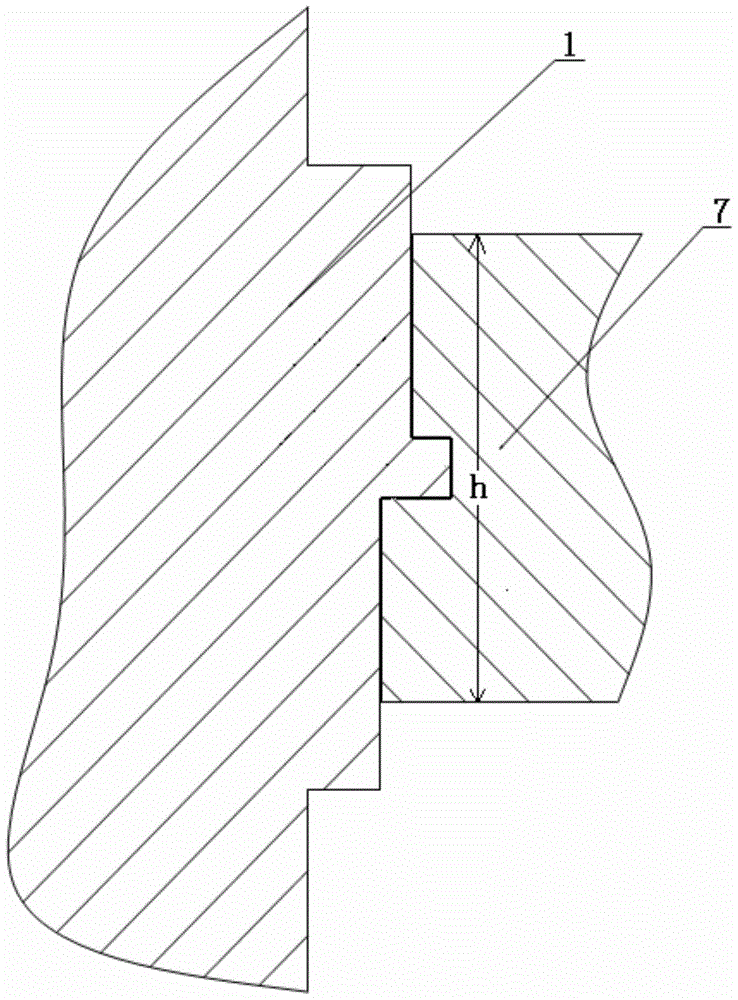

[0034] Such as figure 1 , Figure 6 As shown, the roll ring 7 is divided into a roll ring upper part 71, a roll ring middle part 72 and a roll ring lower part 73, and the inner diameter of the roll ring upper part 71 is The inner diameter of the middle part 72 of the roller ring The inner diameter of the lower part 73 of the roller ring Such as figure 2 , Figure 6 As shown, the roller shaft 1 is divided into an upper connecting portion 104, an upper matching portion 101 (the outer diameter of which is ), the middle fitting part 102 (its outer diameter size ), the lower fitting part 103 (its outer diameter size ) and the lower connection part 105, such as image 3 As shown, the upper fitting part 101 of the roller shaft 1 is an interference fit with the upper part 71 of the roller ring, the middle fitting part 102 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com