Rectangular coordinate system bin packing robot electric control system

A technology of electrical control system and rectangular coordinate system, which is applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of unsatisfactory production enterprises, low production efficiency, and inaccurate counting for a long time, and meet the needs of large-scale mass production , Improve production efficiency and reduce the effect of insufficient quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

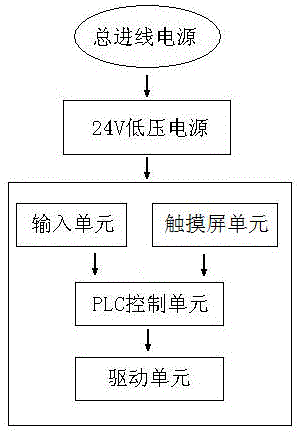

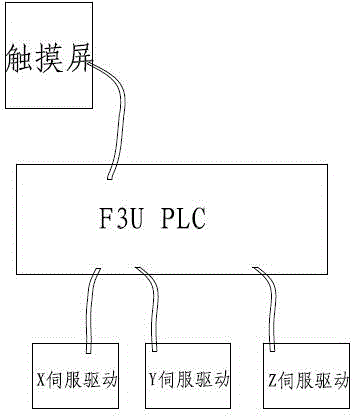

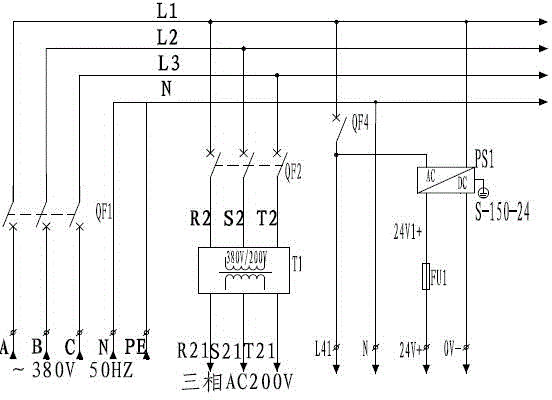

[0020] Such as figure 1 To Figure 8 As shown, the electrical control system of the packing robot in the Cartesian coordinate system, the main incoming power supply, input unit, touch screen unit, PLC control unit and drive unit, the main incoming power supply is connected to each unit, supplies power to the main circuit, and its control circuits Power supply, the input unit is connected to the PLC control unit, sends control signals to the PLC control unit, the touch screen unit sends data to the PLC control unit, the PLC control unit is connected to the drive unit, controls the action of the drive unit, and the PLC control unit receives the control signal from the input unit automatically Record how to proceed to the next step, and then control the drive unit to proceed to the next step; the main incoming power supply is connected to 24V low-voltage power supply, three-phase 200V power supply, single-phase 220V power supply, and 24V low-voltage power supply to the low-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com