Method for manufacturing composite anti-reverse structure suitable for heavy-duty traffic conditions

A manufacturing method and a composite technology, applied in the direction of road construction reinforcements, etc., can solve the problems of being easily punctured by sharp gravel, difficult to control the quality, and reduced crack resistance performance, so as to improve the controllability of product quality and save on-site Construction time, effect of preventing oxidation or corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

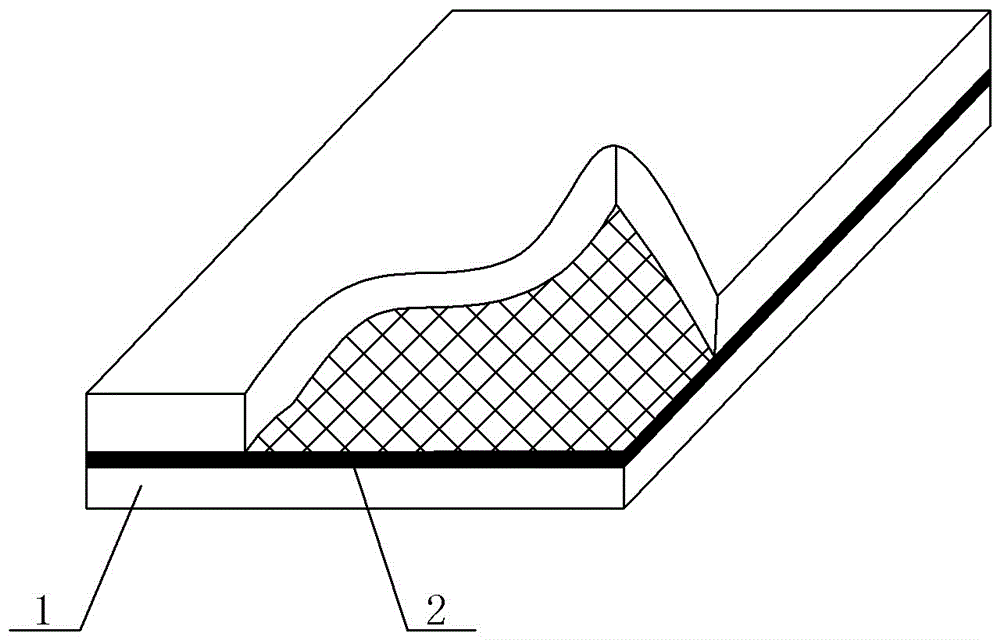

[0031] Composite anti-reverse structure suitable for heavy-duty traffic conditions, basically as figure 1 Shown: The composite anti-reverse structure suitable for heavy-duty traffic conditions is located between the cement concrete base and the asphalt surface, including stainless steel wire mesh 2, and HZ / ZD-4 shrinkage caulking material that wraps the stainless steel wire mesh 2 as a whole Layer 1.

[0032] The composite anti-reverse structure disclosed in this embodiment has excellent flexibility, and no deformation or damage will occur when it is bent 180° around the central axis.

[0033] The HZ / ZD-4 shrinkage caulking material layer 1 in this embodiment can be replaced by an anti-corrosion adhesive layer, and the stainless steel wire mesh 2 can be replaced by a galvanized iron mesh or a high-strength carbon fiber mesh or a high-strength plastic mesh. The materials used in the above composite anti-reverse structure, such as HZ / ZD-4 shrinkage caulking material layer, anti...

Embodiment 2

[0035] Application of composite anti-reverse structure suitable for heavy-duty traffic conditions: use polyurethane adhesive (or epoxy cement or hot asphalt or high-viscosity emulsified asphalt) to bond the bottom surface of the composite anti-reverse structure in Example 1 to cement On the concrete base, the asphalt surface layer is added on the top surface of the composite anti-reverse structure.

Embodiment 3

[0037] A method for manufacturing a composite anti-reverse structure suitable for heavy-duty traffic conditions, comprising the following steps:

[0038] ① Customize the forming mold according to the thickness requirement;

[0039] ② Brush transparent soybean oil on the inner surface of the mold;

[0040] ③ Place the stainless steel wire mesh in the side groove of the mold;

[0041] ④ Pour HZ / ZD-4 shrinkage caulking material into the side groove of the mold at room temperature, so that it is completely wrapped and adhered to the stainless steel wire mesh to form a sealed adhesive layer. The curing principle of HZ / ZD-4 shrinkage caulking material is: HZ / ZD-4 shrinkage caulking material is sealed in a plastic bucket, and it is in a fluid state at room temperature (about 25°C), and it will cure when it meets air.

[0042] ⑤Stay for 4 hours to demould, and complete the manufacture of the composite anti-reverse structure, the final thickness of the composite anti-reverse structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com