Using 3D printing to make a joint sample method with a structural surface with specific geometric features

A technology of geometric features and 3D printing, applied in the preparation of test samples, etc., can solve the problems of unsatisfactory joint shape sample preparation and difficult operation of joint rock sample preparation, and achieve the effect of simple and fast sample preparation process and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

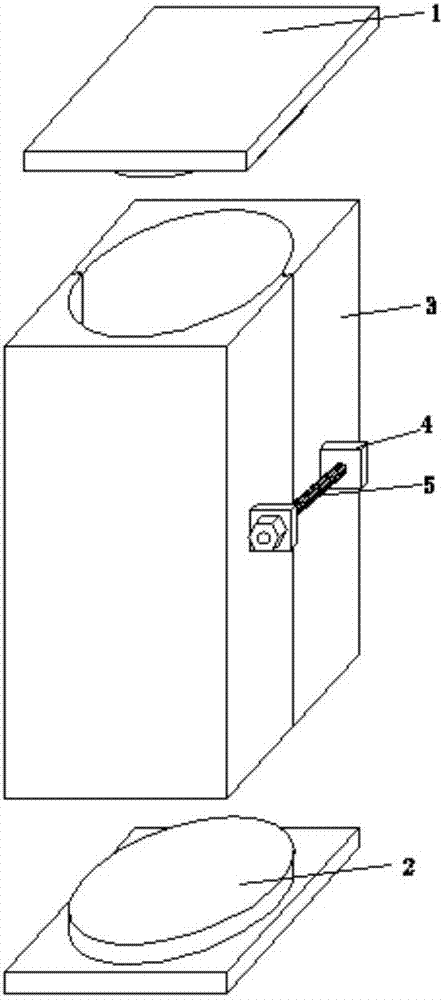

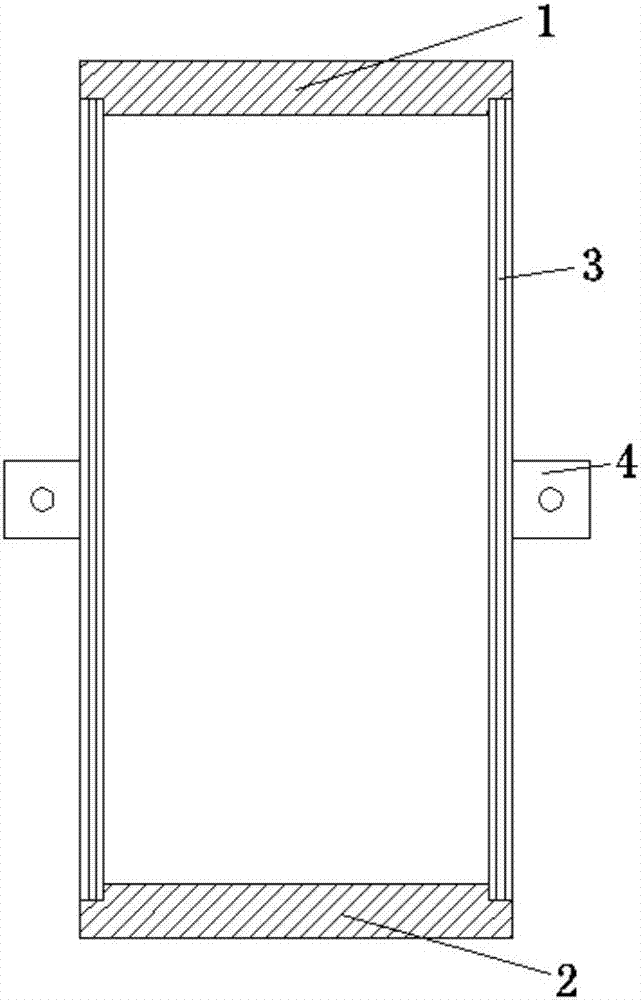

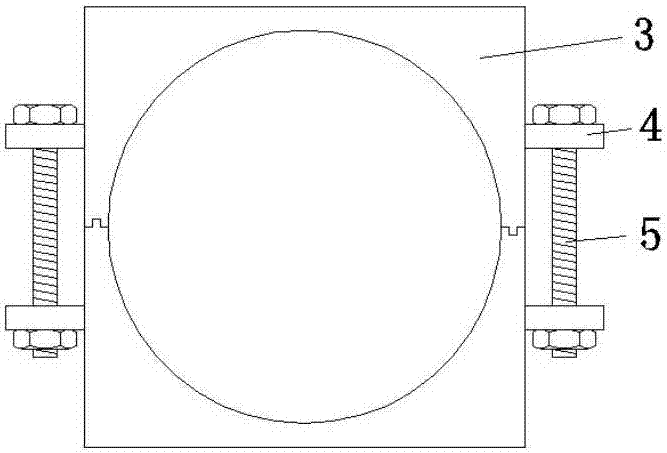

[0030] The preparation method of the rock-like sample of the jointed rock mass includes: structural surface design and mold printing, assembly of the sample preparation box and the mold, pouring of similar materials, demoulding and sample maintenance; Contour scanning technology obtains the appearance of the actual rock mass structural surface; after passing the designed structural surface through the complete cylinder model in the 3D drawing software, the two-part complementary test block model obtained by segmentation is obtained through Boolean operations, and the two parts of the test block model are separated by using a 3D printer. The block models are printed and formed separately; the printed molds are placed in two sample preparation boxes and assembled, and similar materials are poured into the sample preparation boxes, and the molds are removed and maintained after they are solidified; The standard sample of the structural surface; prepare the jointed rock mass with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com