An aging device for a charger

A technology of burn-in device and charger, which is applied in the field of burn-in device and charger burn-in device, which can solve the problems of multi-manpower and material resources, affecting work efficiency, cost, etc., and achieve the effect of extensive centralized aging test and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

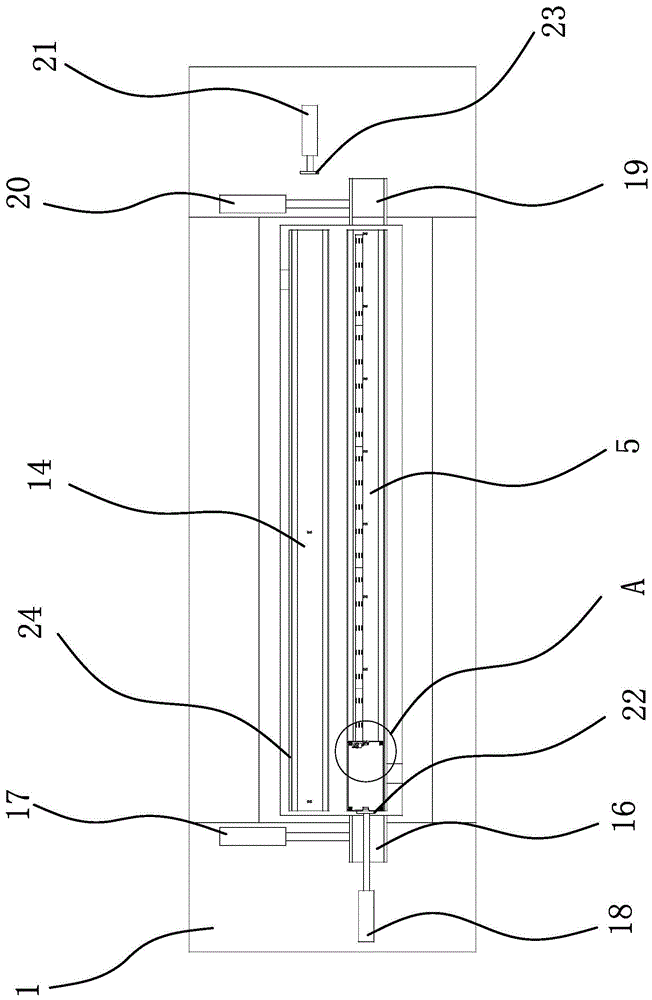

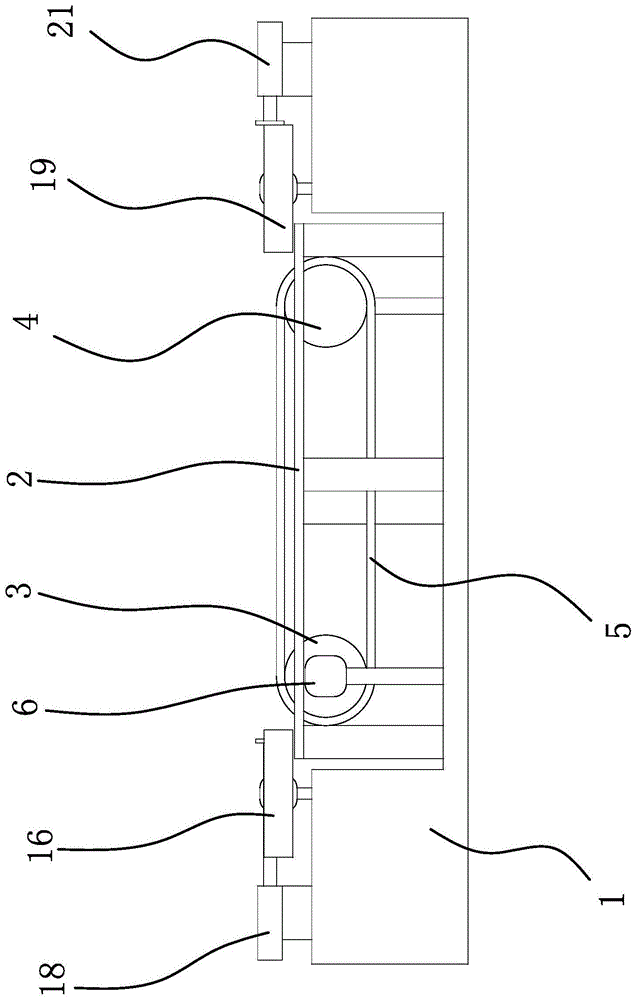

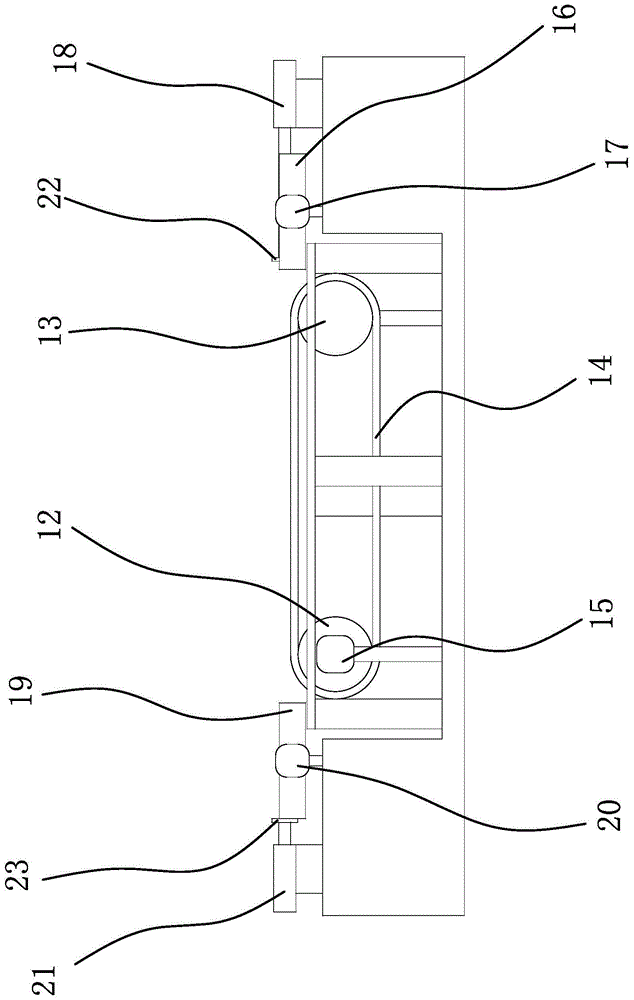

[0037] Such as figure 1 , figure 2 and image 3 As shown, an aging device for a charger includes a frame 1 , a workbench 2 fixed on the frame 1 , and an aging car set on the workbench 2 . Wherein, one side of the workbench 2 is provided with a transport mechanism capable of transporting aging vehicles from one end of the workbench 2 to the other end, and the other side of the workbench 2 is provided with a turning mechanism capable of resetting the tooling plate 9 .

[0038] Such as figure 2 and image 3 As shown, specifically, the transportation mechanism includes a driving roller-3, a driven roller-4 and a transmission belt-5 sleeved between the driving roller-3 and the driven roller-4, and a servo motor is horizontally fixed on the workbench 2 16. The output shaft of the servo motor 16 is connected with the driving roller 13 through a coupling. The driving roller 13 and the driven roller 4 are set on the workbench 2 through the rotating shaft, bearing and bearing seat...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in Embodiment 1, the positioning structure includes grooves 1 and 2 on both sides of the burn-in disk and fixed on the support partition. Positioning plate one and positioning plate two; and in the second embodiment, the positioning structure includes grooves one and two on both sides of the burn-in plate and positioning plate one and positioning plate two fixed on the support partition, The gap formed between the positioning plate 1 and the positioning plate 2 is used for installing the burn-in disk. Wherein, positioning plate one includes vertical plate one and horizontal plate one horizontally fixed on the top of vertical plate one, the lower plate surface of vertical plate one is fixed on the upper surface of supporting partition, and the lower plate surface of horizontal plate one is fixed on vertical plate one One side of the horizontal plate protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com