A module structure and display device

A module structure and display device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem that the module structure cannot meet the thinning of the module structure, and achieve the effect of meeting the thinning requirements and reducing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

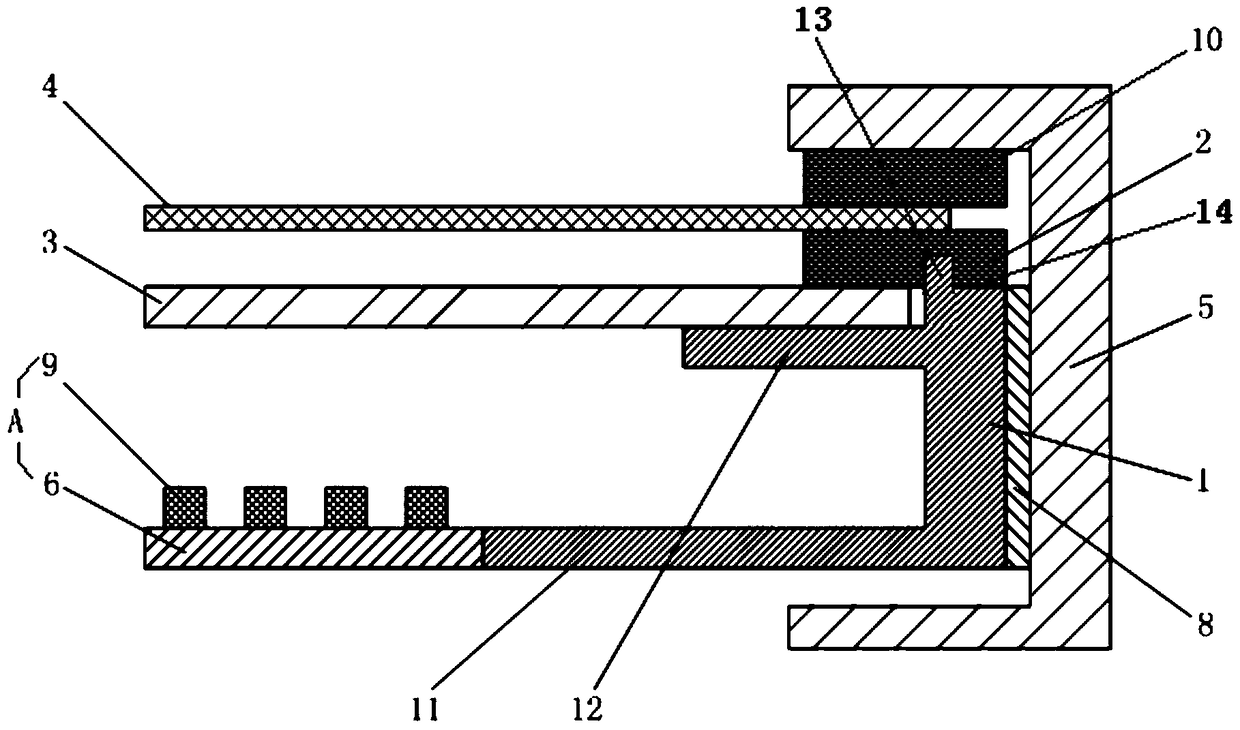

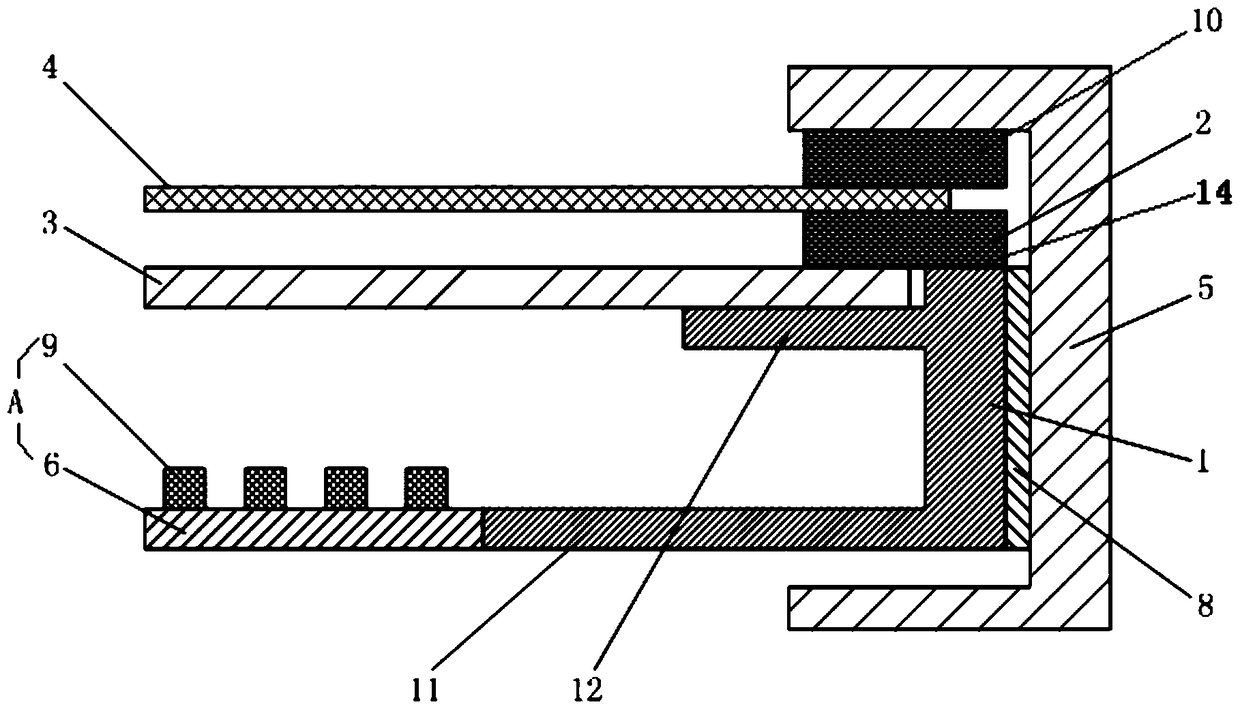

[0079] like figure 1 shown, see also figure 2 , an embodiment of the present invention provides a display device, the display device includes a module structure.

[0080] Since the module structure described in this embodiment includes all the content in Embodiment 1, the same content will not be repeated here.

[0081] The present invention is fixed on the side wall of the frame body 1 close to the end surface 14 of the second inner boss 12 through the rubber pad 2, and the optical film material 3 is installed between the second inner boss 12 and the rubber pad 2, reducing the module structure The thickness meets the thinning requirements of current liquid crystal display production.

[0082] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com