Power module package and method of manufacturing the same

一种电源模块、电源装置的技术,应用在半导体/固态器件制造、电路、电气元件等方向,能够解决昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

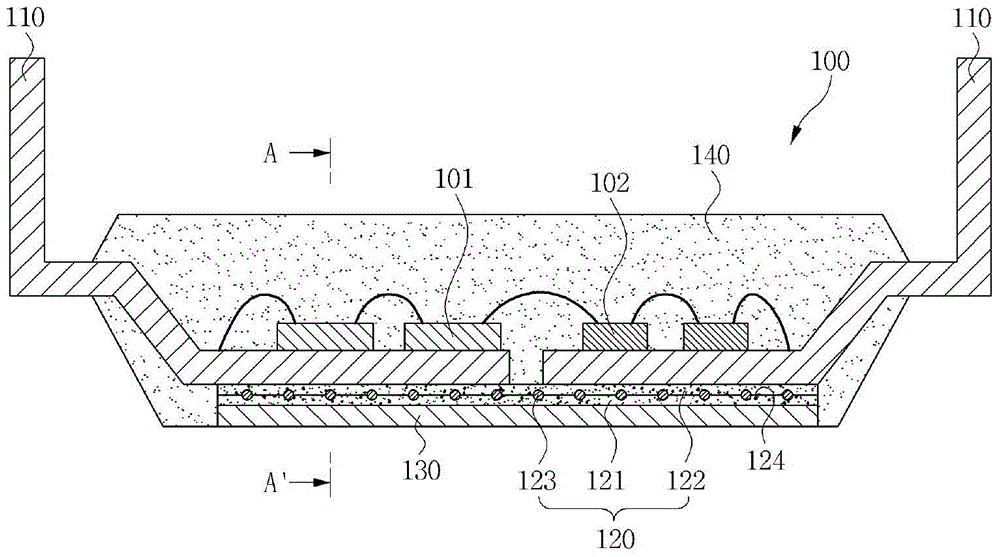

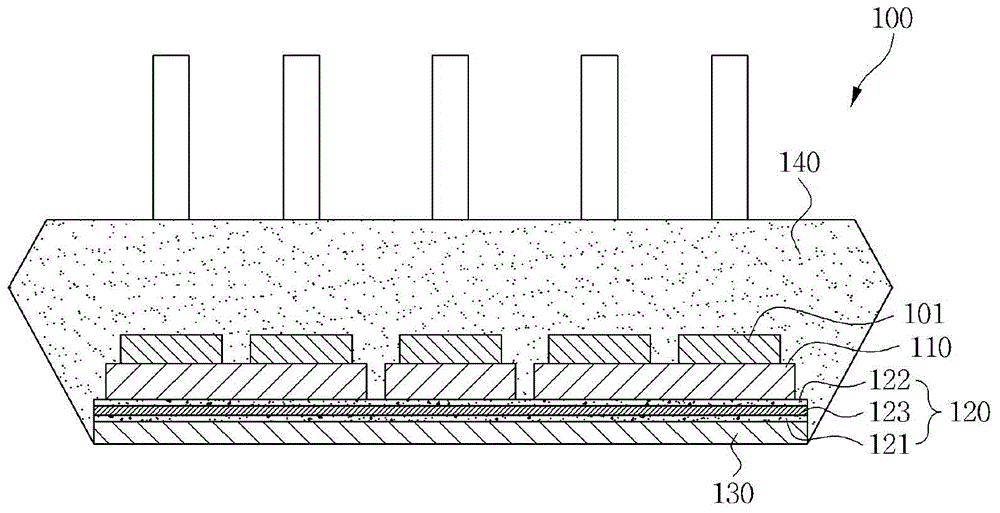

[0054] Such as Figure 6 to Figure 11 As shown, the method for manufacturing a power module package according to a specific embodiment of the present invention mainly includes preparing the heat conduction sheet 120 and manufacturing the power module package 100 using the heat conduction sheet 120 .

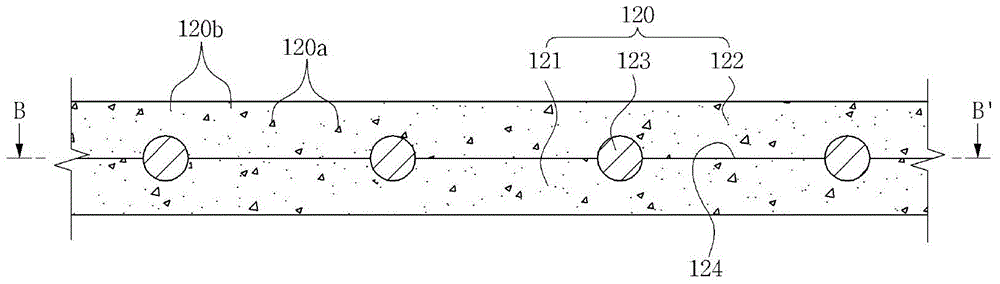

[0055] The thermally conductive sheet 120 includes a first resin layer 121 and a second resin layer 122 made of organic materials such as prepreg, epoxy, polyimide, liquid crystal polymer, and the like.

[0056] Here, the first resin layer 121 and the second resin layer 122 include 80% or more of an inorganic filler having thermal conductivity, and the inorganic filler may be selected from the following group of substances, for example, aluminum oxide (Al 2 o 3 ), aluminum nitride (AlN), silicon nitride (SiN), silicon dioxide (SiO 2 ), silicon carbide (SiC), or a combination thereof, and a mixture 120b of phenyl glycidyl ether (PGE) and alkyl glycidyl ether mixed at a mixing ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com