Remote monitoring system and method for grease storage based on wireless sensor network

A wireless sensor and remote monitoring technology, applied in the transmission system, signal transmission system, network topology, etc., can solve the problems of real-time monitoring of oil storage status, failure, and loss of oil tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

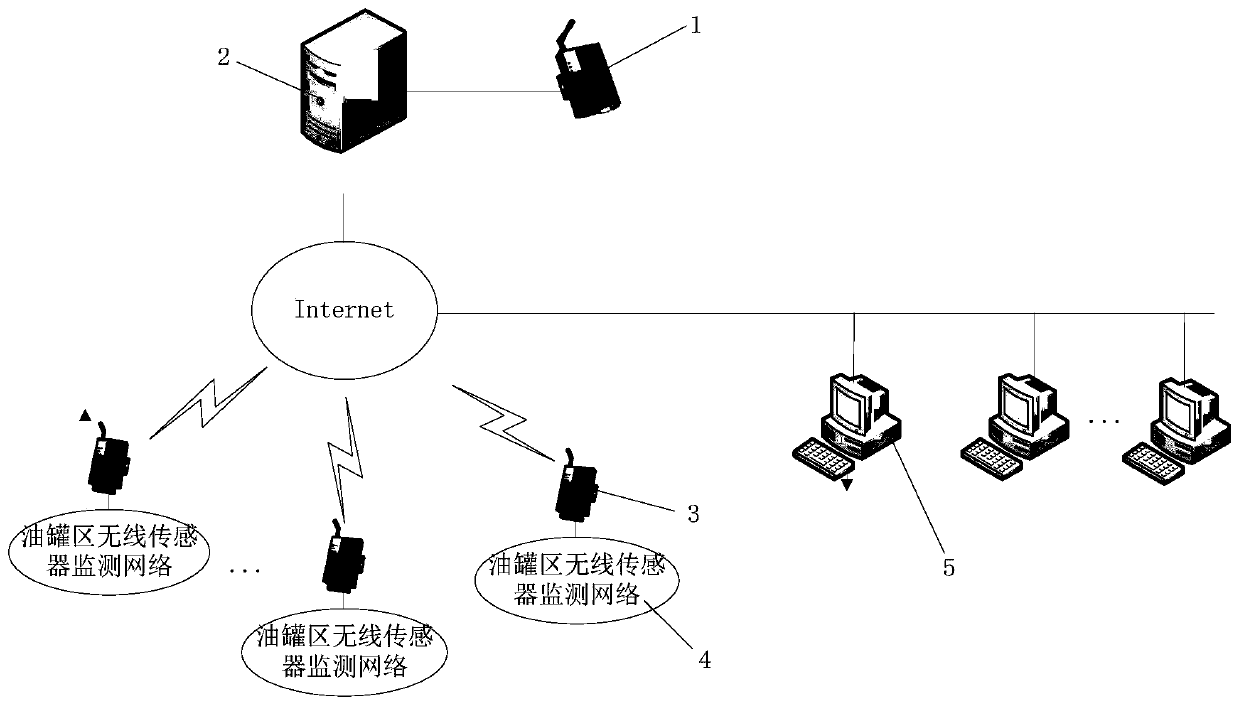

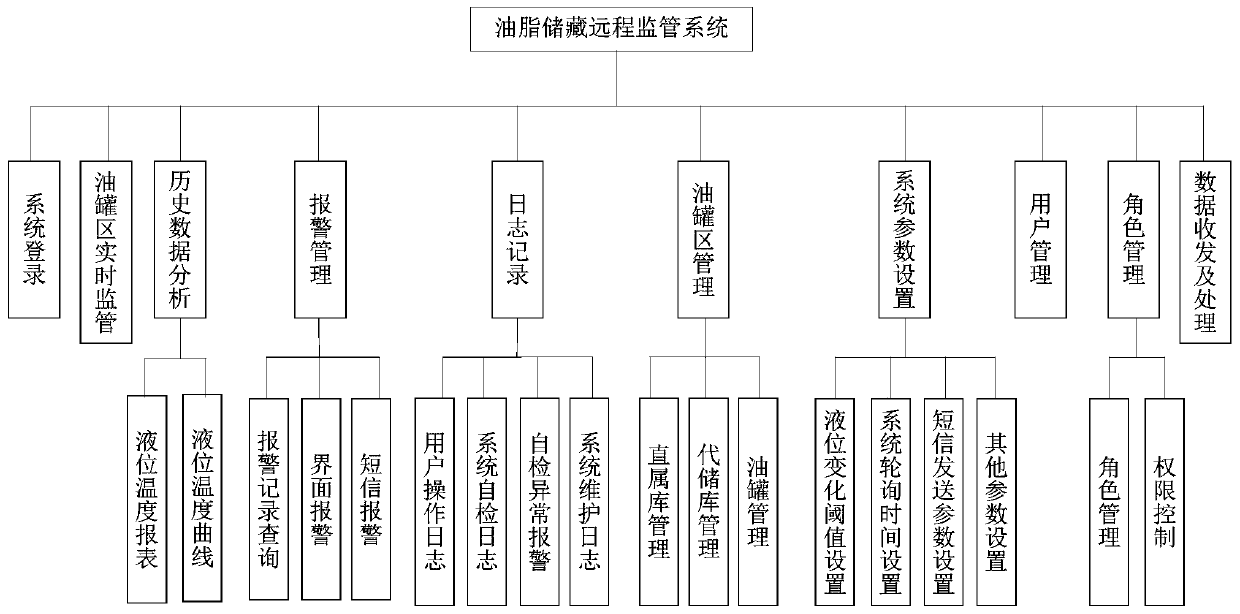

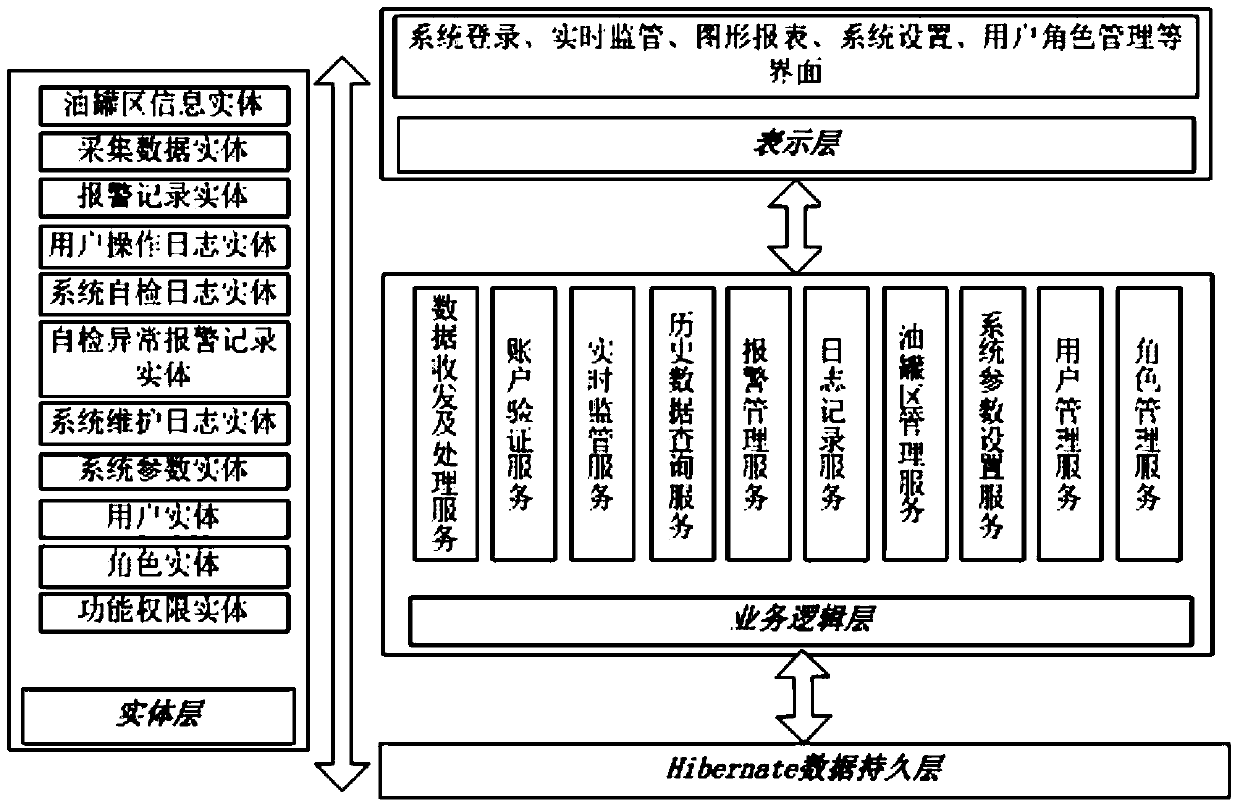

[0095] like figure 1 As shown, a remote monitoring system for oil storage based on wireless sensor network, including a SMS modem module 1 for sending alarm messages, a WEB system server 2 installed with database management system software and remote monitoring system software for oil storage, and a DTU wireless transmission module 3 and wireless sensor monitoring network for oil tank farm4. like figure 2 As shown, the oil storage remote supervision system software includes a system login module, a real-time supervision module for oil tank farms, a historical data analysis and query module, an alarm management module, a log recording module, a tank farm management module, a system parameter setting module, a user management module, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com