Construction of the descending forehearth with double cleaning unit for the unit for gluing granules during the production of material boards

A technology of cleaning device and material board, which is applied in the cleaning method of using tools, pretreatment of molding materials, wood processing equipment, etc., can solve the problems of high cost, easy to get dirty in the descending channel, and difficult to achieve high-efficiency sealing, etc., to achieve High self-cleaning properties, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

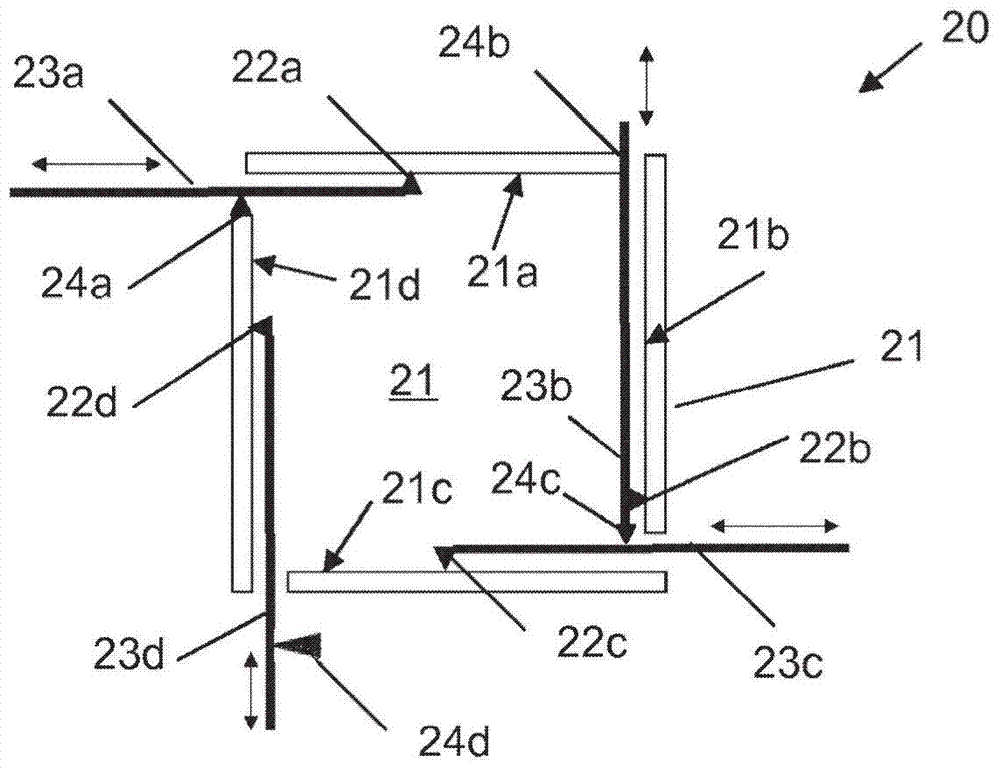

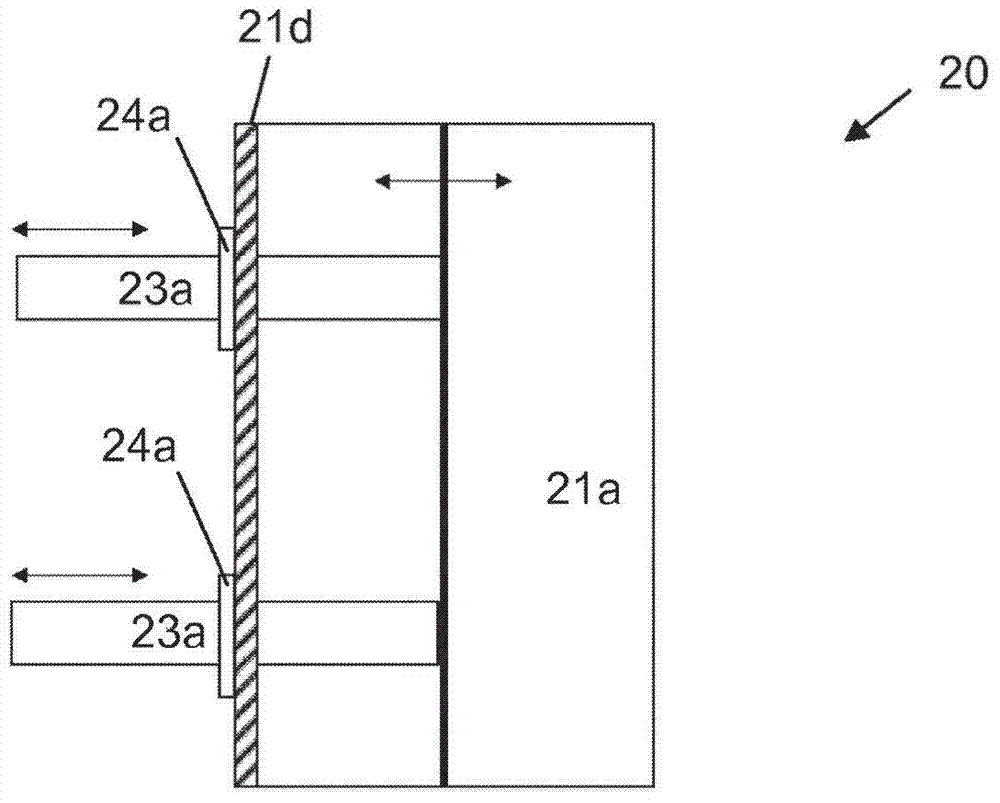

[0086] Due to the large number of embodiments, the reference numerals 21x, 23x, 24x, 31x, 32x, 33x, 34x are subsequently introduced as references to multiple components, a to d being used instead to denote x.

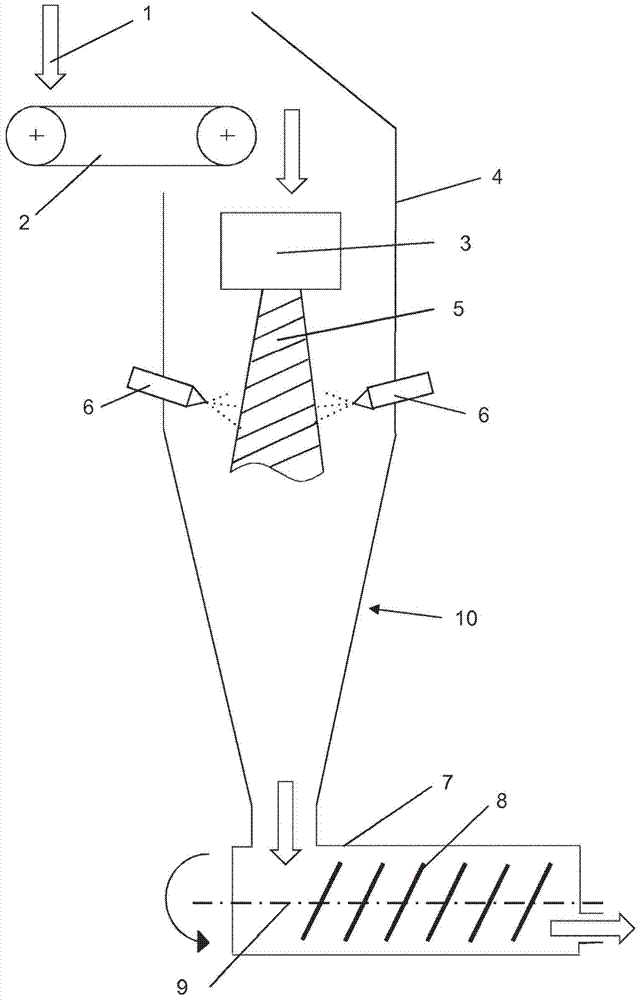

[0087] exist figure 1 A schematic diagram of an overall view of the device for gluing granules with the metering device 2 at the beginning and the mixing device 7 at the end is shown schematically in . A descending channel 3 and a descending channel structure 10 which will be further described below are arranged between the dosing device and the mixing device. Here, the granules are fed as a granulate stream 1 from the granulate silo into the dosing device 2 , usually by means of a discharge device, are weighed there, and enter the descending feeder via a conventional belt regulator (not shown) for dosing. Road 4. In the downcomer, the particle flow or particles 1 are dispersed and / or distributed onto the dispersion device 3 and there dispersed and / or distributed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com