Coupling bodies for synchronizing devices of motor vehicle gear transmissions

A technology for gear transmissions and motor vehicles, applied in the direction of mechanical drive clutches, clutches, mechanical equipment, etc., can solve the problems of high manufacturing costs and achieve the effect of avoiding cutting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

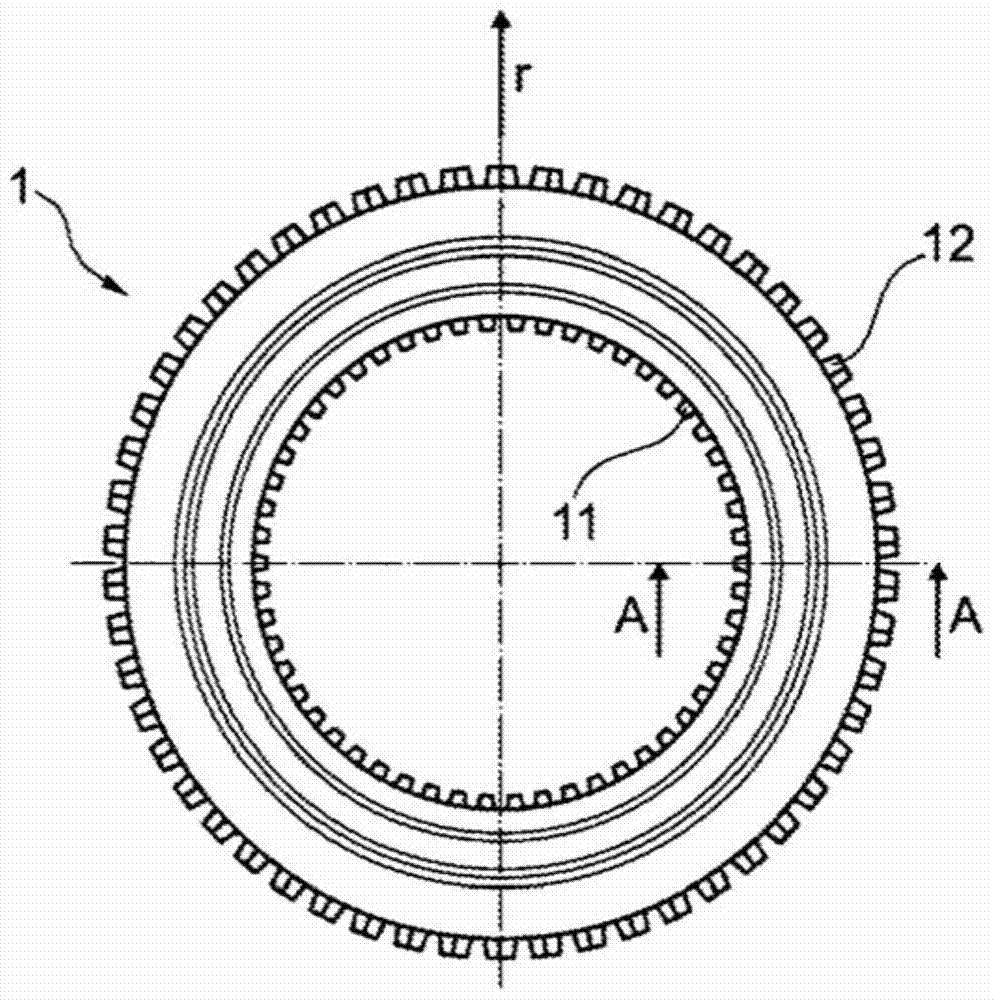

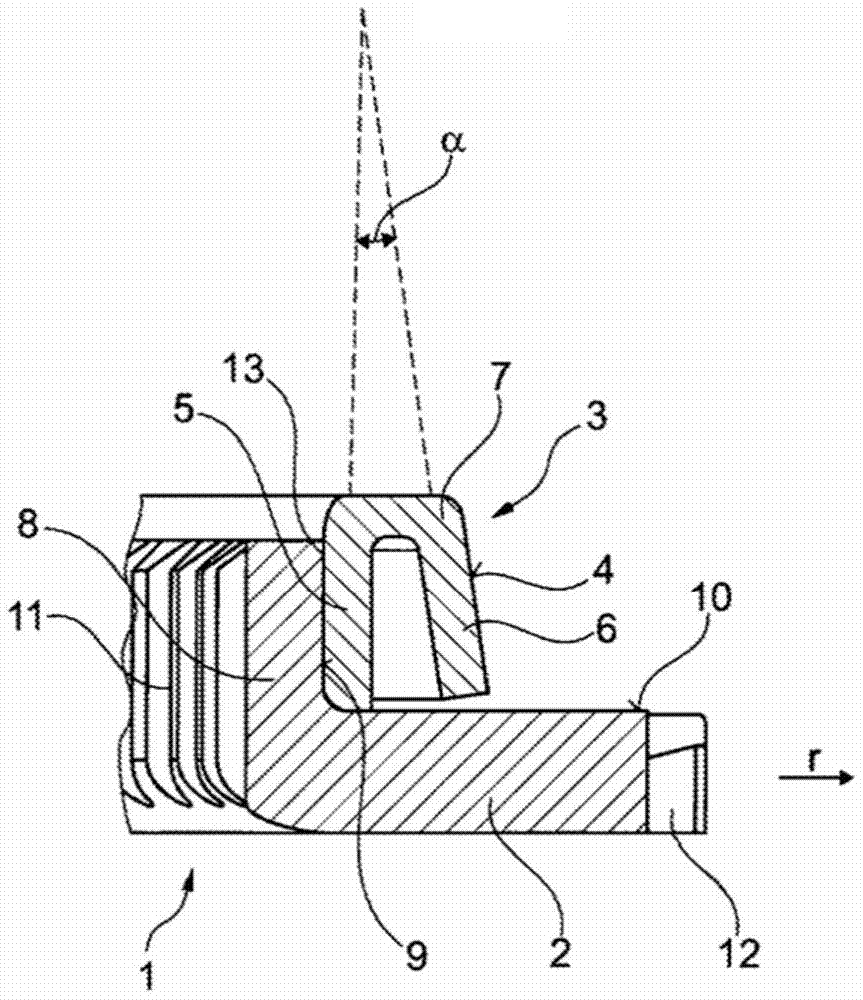

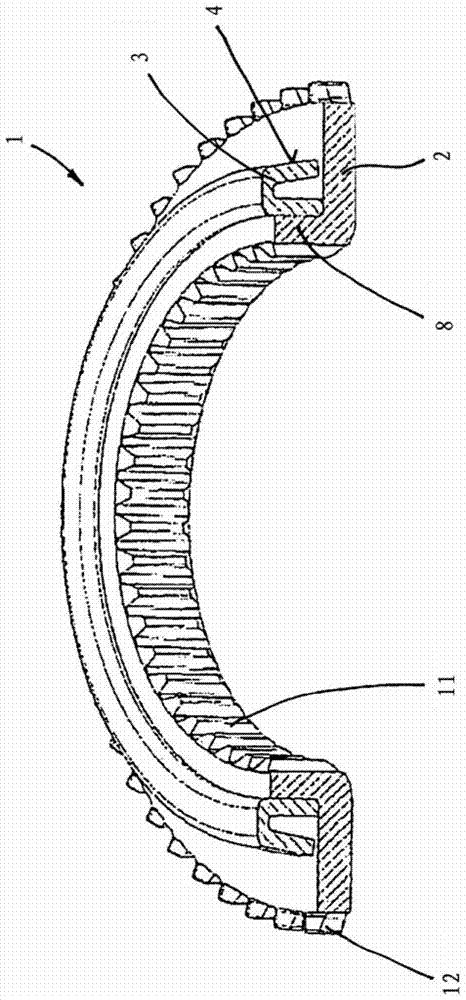

[0027] exist Figures 1 to 3 A first embodiment of the present invention is schematically shown in FIG. A coupling body 1 is shown in different views, which belongs to a synchronization device of a gear transmission of a motor vehicle. The coupling body 1 is designed in two parts.

[0028] A part of the coupling body 1 is formed by the coupling disc section 2, which is in the radial section (for this best see figure 2 ) has an L-shaped profile. The second part of the coupling body 1 is formed by a friction cone 3 which has a friction cone surface 4 and is connected to the coupling disk section via a permanent connection 13 .

[0029] The two parts 2 and 3 can be produced by simple production technology processes. First, the ring-shaped part is punched or punched out of the sheet metal strip. The parts 2 and 3 shown are produced by shaping, die-casting and / or deep-drawing, wherein machining by cutting can be dispensed with. The two parts 2 and 3 are thus connected to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com