Vessel for cooking food for induction or conventional surfaces and forming method for vessel

A cooking container and induction technology, applied in the field of forming the cooking container, can solve the problems of non-permanent connection, unreliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

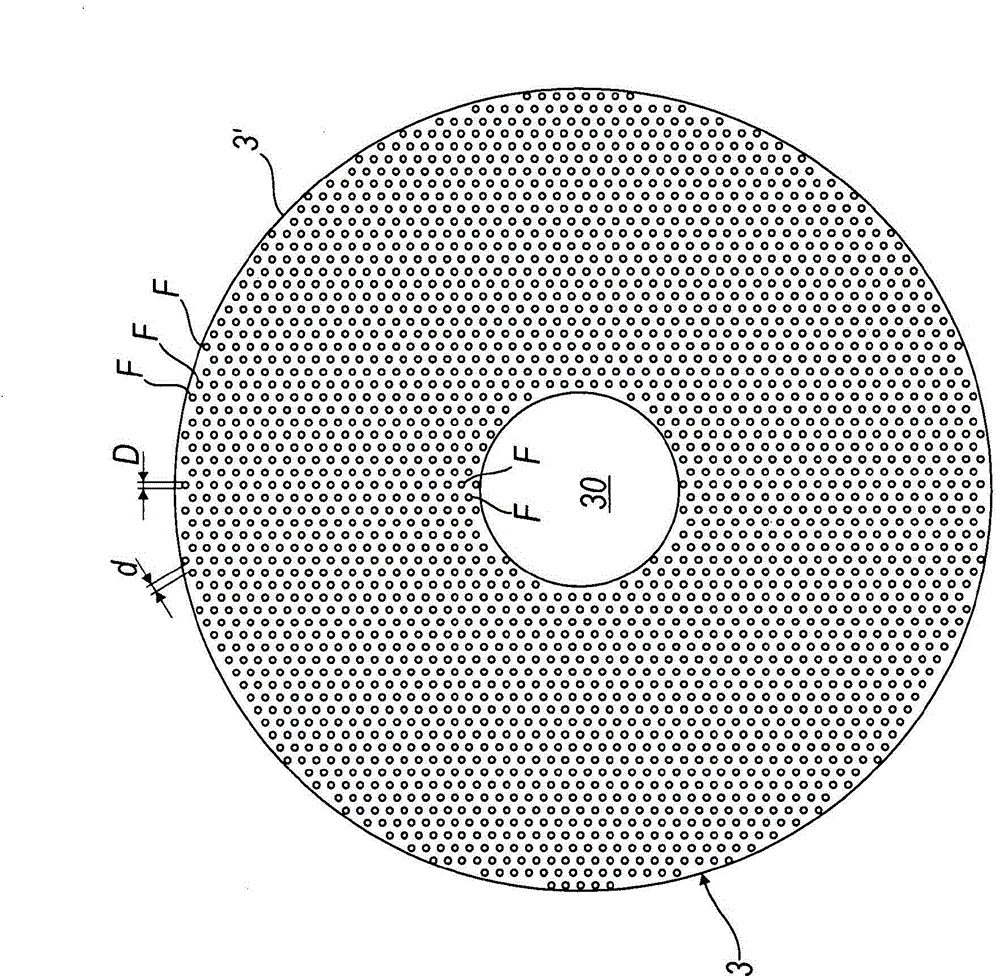

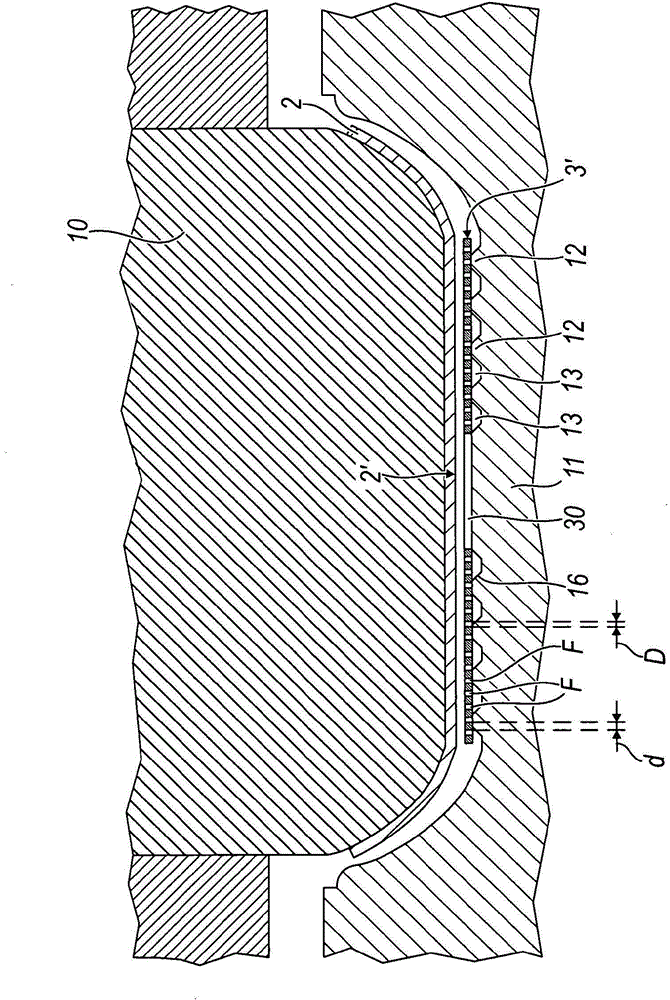

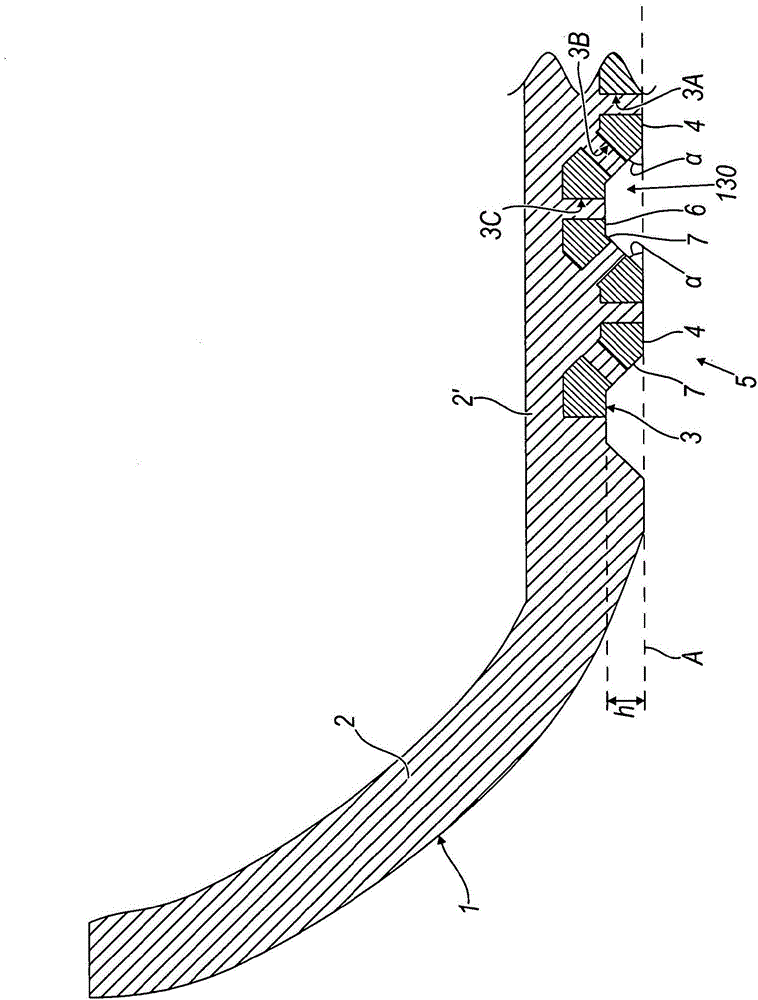

[0037] With reference to the drawings described above, a container for cooking food on an induction surface or a conventional surface is shown generally indicated by the reference number 1 .

[0038] Said container 1 comprises a shaped body 2 provided with surfaces defining a volume for containing food during cooking.

[0039] Preferably, the body is made of aluminum or another malleable material suitable for cooking.

[0040]Aluminum is known to be unsuitable for use on inductive surfaces. Because aluminum is actually a non-magnetic material.

[0041] Preferably, the body 2 is made of non-magnetic material.

[0042] Thus, in order to enable the container to be used also on such surfaces, the shaped body is coupled to a metal element 3, preferably made of ferromagnetic material (for example, ferritic stainless steel), which placed on the bottom of the container.

[0043] especially as in image 3 As seen in , the bottom 5 of the container 1 has a plurality of first surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com