Recovery technology for volatile oil gas in lightweight aromatic hydrocarbons filling process

A technology for light aromatic hydrocarbons and oil and gas, which is applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve the problems of reducing process recovery efficiency and process difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

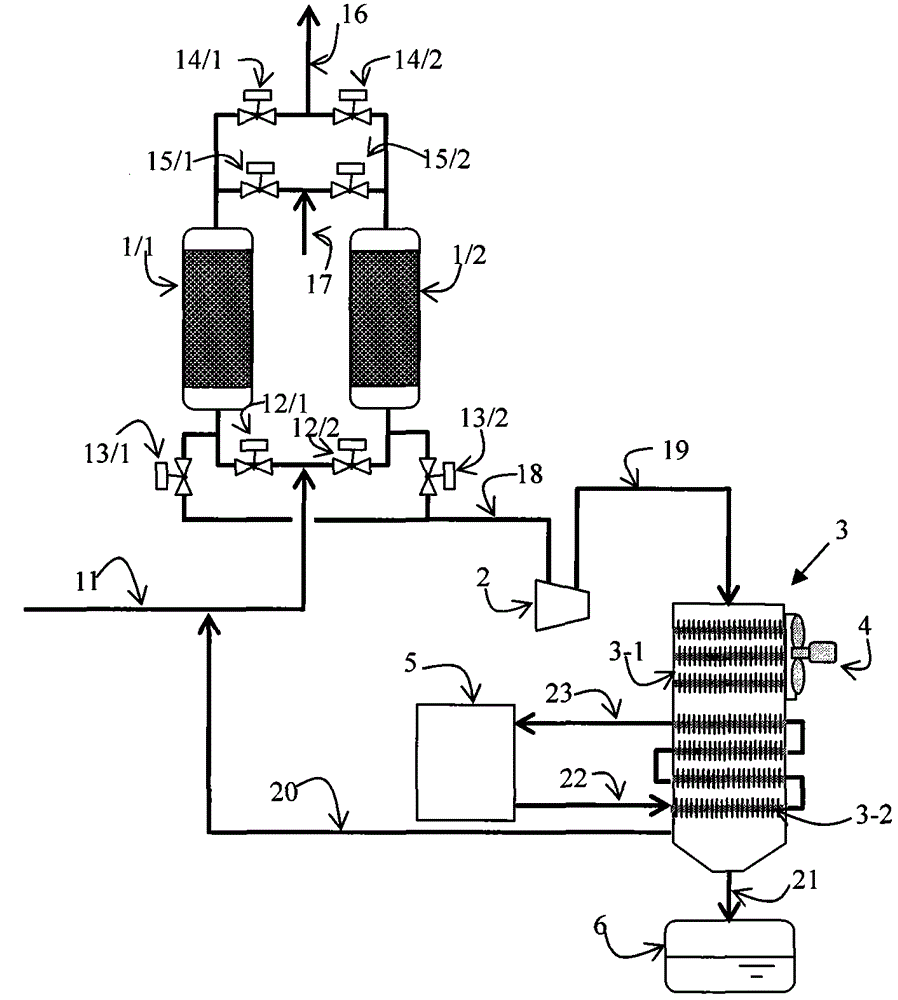

Image

Examples

Embodiment 1

[0042] A liquid benzene car loading platform has an annual loading capacity of 150,000 tons of benzene. During the loading operation, the liquid benzene loading rate is 200t / h, the loading liquid benzene temperature is 30 °C, and the average benzene concentration during the loading process is 12v%. of benzene gas 245Nm 3 / h, the amount of benzene brought out with oil and gas is 97.1kg / h. The recovery process of the present invention is used to treat benzene gas, the adsorbent is silica gel, the vacuuming pressure is 2kpa, the vacuum stripping pressure is 4kpa, the first condensing temperature is 40°C, and the second condensing temperature is controlled at 7±1°C. The average benzene concentration of the purified tail gas after recovery and treatment by the recovery device is 3mg / m 3 , lower than the national emission standard of 12mg / m3. The amount of benzene discharged into the atmosphere with the purified tail gas=245*(1-12%)*3=647mg / h=0.000647kg / h, the benzene recovery rat...

Embodiment 2

[0044] A liquid toluene train loading platform has an annual loading capacity of 100,000 tons of toluene. During the loading operation, the liquid benzene loading rate is 300t / h, the loading liquid toluene temperature is 30 °C, and the average toluene concentration during loading is 4v%. of toluene vapour 350Nm 3 / h, the amount of toluene carried out with oil and gas is 54.5kg / h. The recovery process of the present invention is used to treat toluene oil and gas, the adsorbent is resin, the vacuuming pressure is 1kpa, the vacuum stripping pressure is 3kpa, the first condensation temperature is 40°C, and the second condensation temperature is controlled at 0°C. The purified tail gas after recovery by the recovery device Average benzene concentration 2mg / m 3 , much lower than 40mg / m 3 national emission standards. The amount of toluene discharged into the atmosphere with the purified tail gas=350*(1-4%)*2=672mg / h=0.000672kg / h, toluene recovery rate=(54.5-0.000672) / 54.5=99.998%≈...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com