Molten iron filtering apparatus for casting

A filtering device and molten iron technology, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of complex operation, low space utilization, inability to solve slag and impurities, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

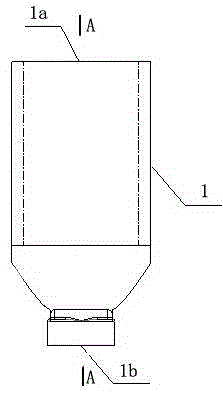

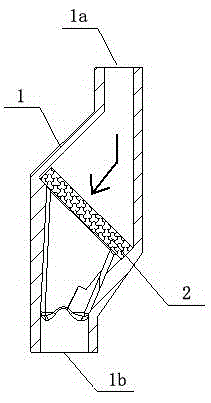

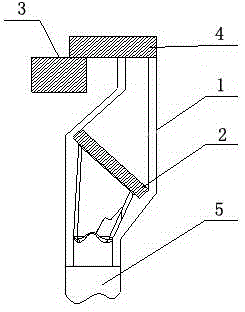

[0012] Such as figure 1 , figure 2 and image 3 Shown is the molten iron filtering device for casting runners of the present invention, including a ceramic filter seat 1, the ceramic filter seat 1 is provided with an inlet port 1a, an outlet port 1b and an inner cavity pipeline, and the inner cavity pipeline of the ceramic filter seat 1 is provided with an oblique The filter screen 2 that is 30°--60° with the horizontal, in the present embodiment, the angle that is specifically set is 45°, but it is not limited to this angle, the inner wall of the lumen pipeline is provided with an inner wall for fixing the filter screen 2 Steps, the inner mouth of the inlet port 1a is rectangular, the inner mouth of the outlet port is circular, and the diameter of the inner mouth of the ceramic filter seat 1 inlet is larger than the maximum outer edge size of the filter screen 2, so that the filter screen 2 can be placed from the inner mouth of the inlet port. Into the inner cavity pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com