A fpc light guide plate laminating machine

A light guide plate and laminating machine technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of low efficiency and low consistency of manual operations, and achieve high efficiency, intuitive and convenient machine adjustment and repair, The effect of high product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

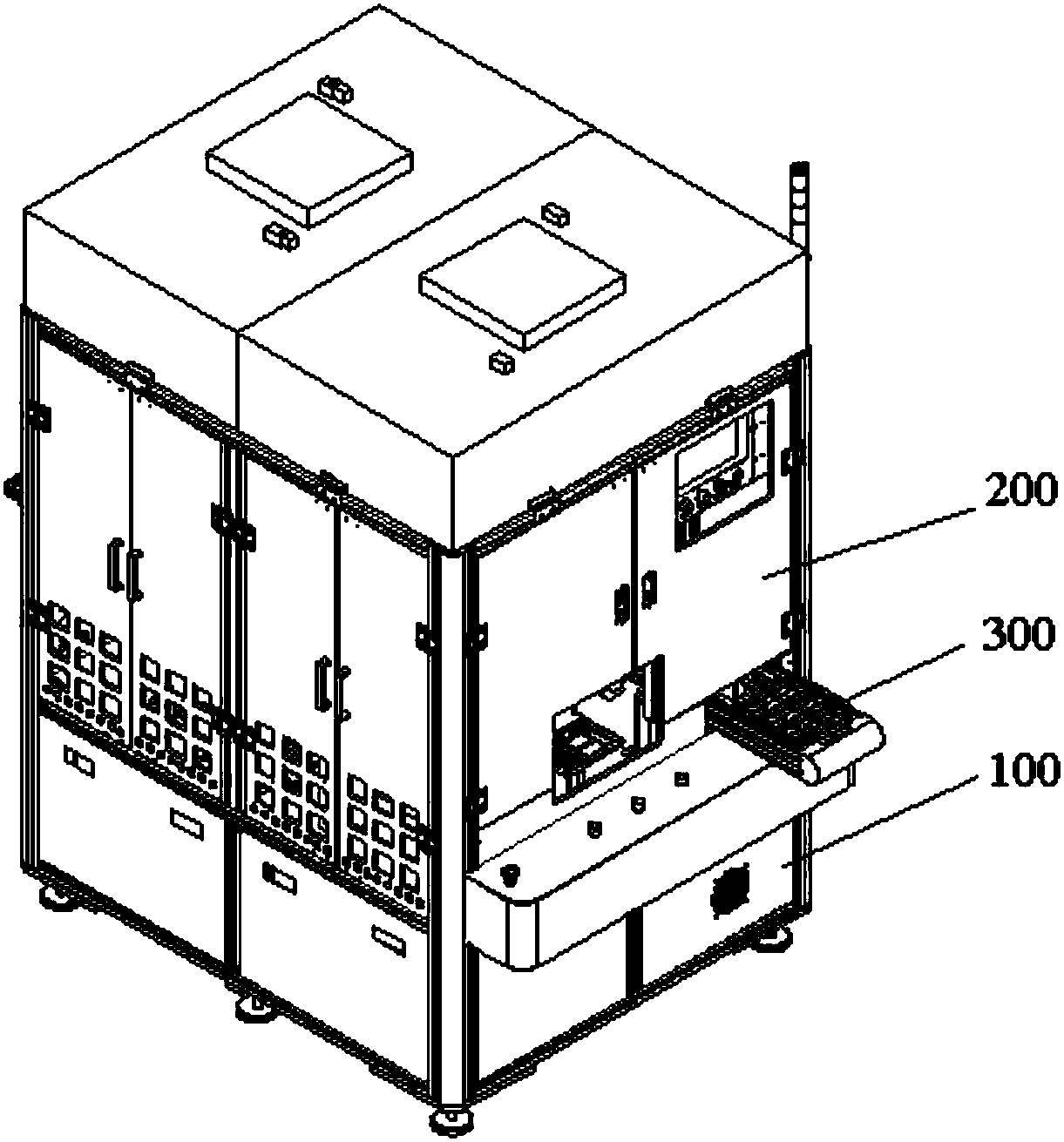

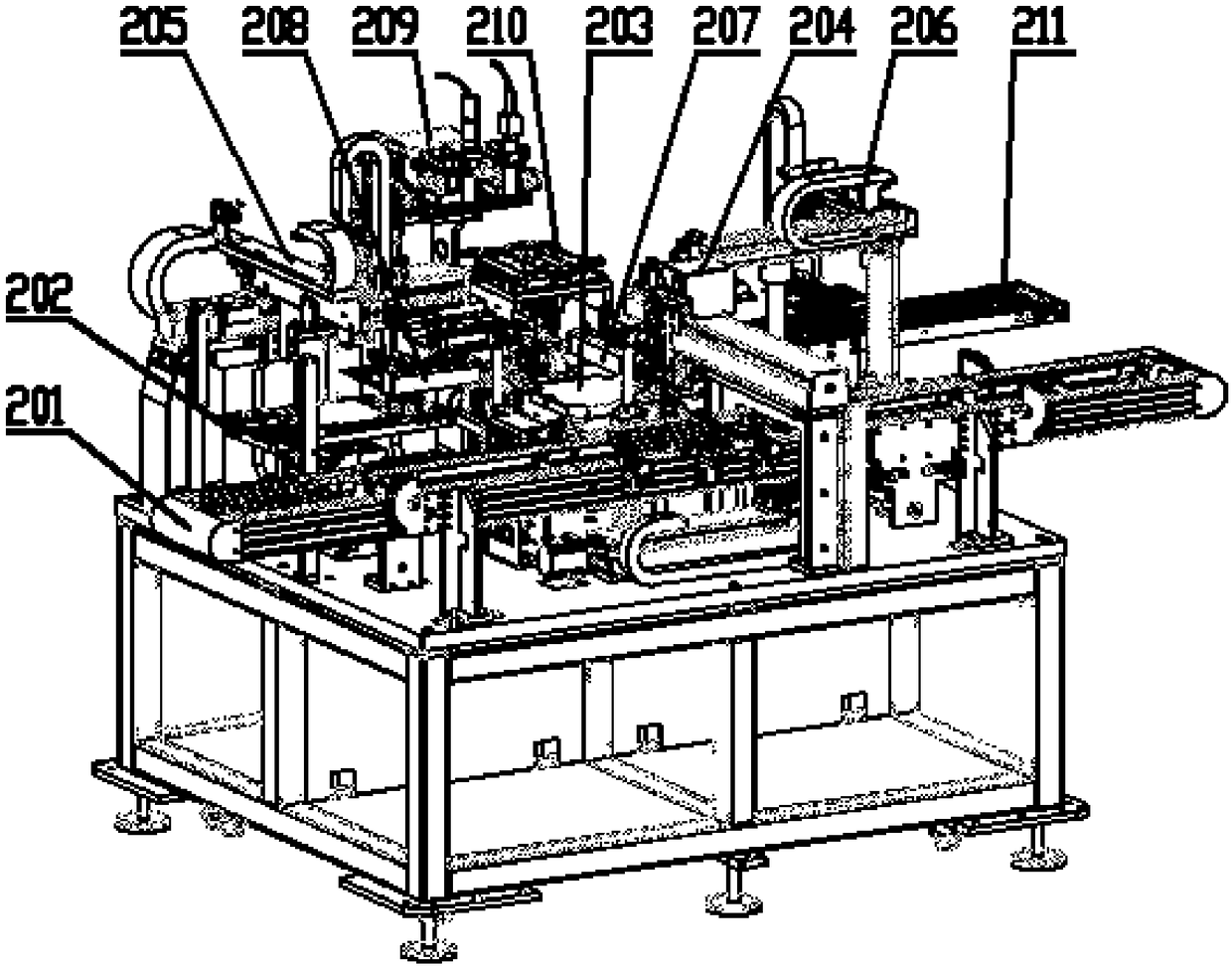

[0030] like figure 1 , figure 2 As shown, the present invention provides an FPC light guide plate laminating machine, including an upper cabinet 200 and a lower cabinet 100, including a first feeding device 201, a second feeding device 202, a first feeding device 201, a second feeding device 202, The third feeding device 203, the first reclaiming device 204, the second reclaiming device 205, the third reclaiming device 206, the first static removing device 207, the second static removing device 208, the 2CCD image alignment device 209, the FPC The light guide plate laminating device 210, the discharging device 211 and the upper cabinet 200, the first reclaiming device 204, the second reclaiming device 205, the third reclaiming device 206, the 2CCD image alignment device 209, the The FPC light guide plate laminating device 210 is located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com