Large heavy vehicle used rim lock ring having mortise and tenon joints

A technology of concave-convex grooves and vehicles, which is applied in the directions of rims, vehicle parts, transportation and packaging, etc., can solve the problems of many personal safety accidents, time-consuming lock ring installation, personal safety accidents, etc., so as to avoid personal safety accidents and lock ring installation. Safe disassembly and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

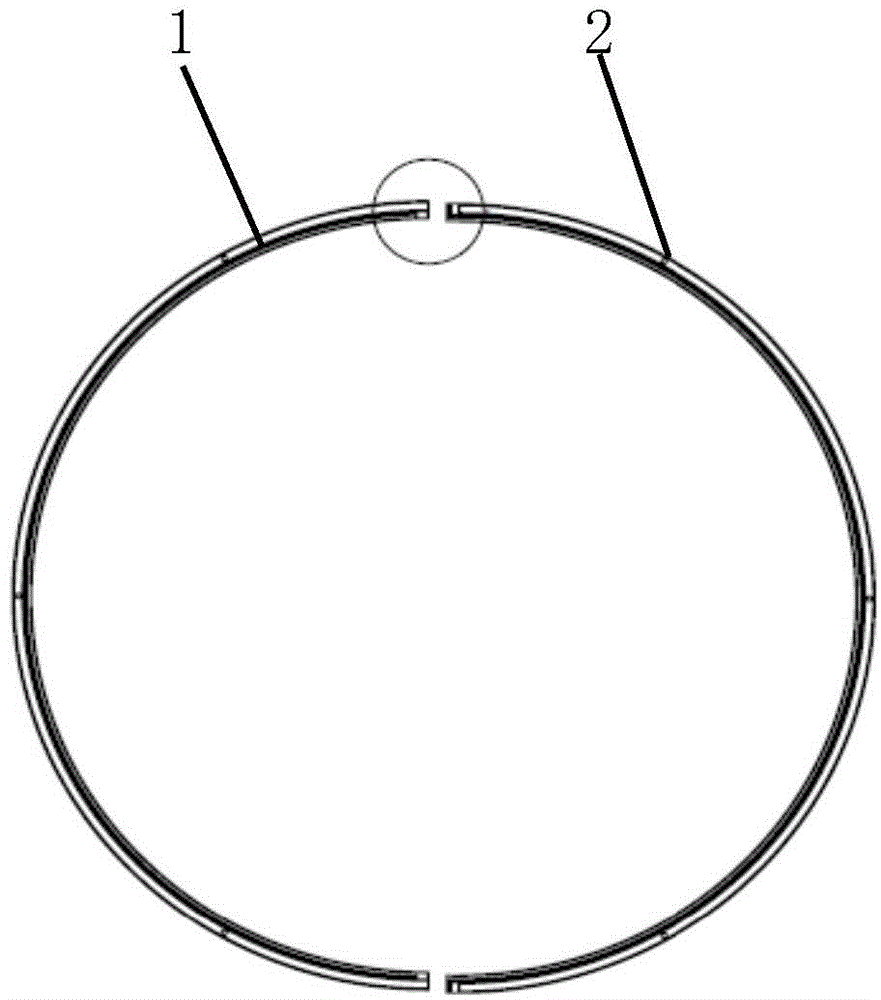

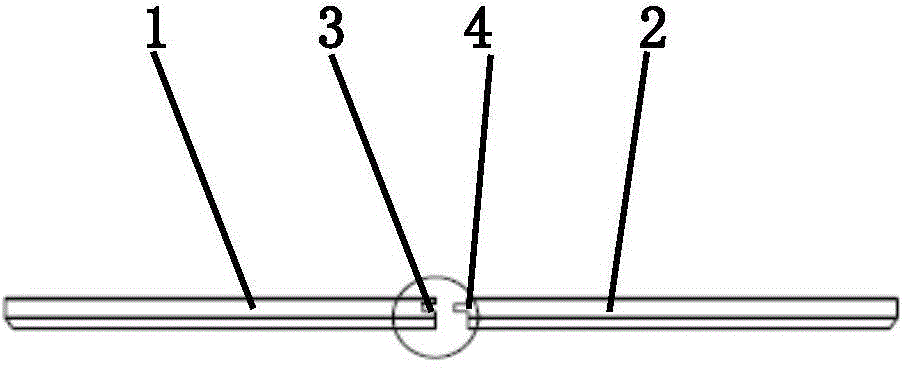

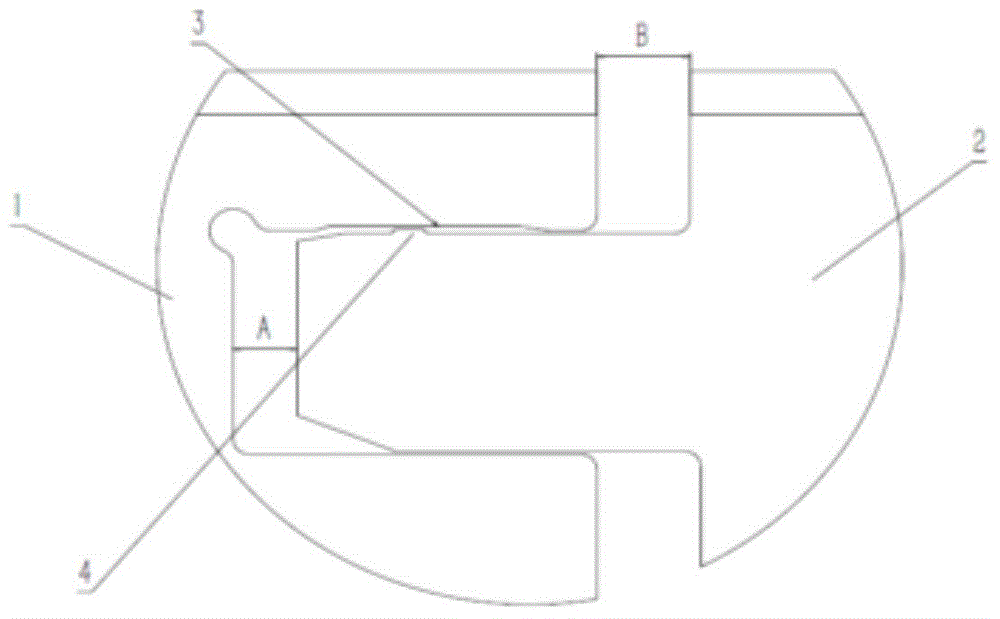

[0039] Such as figure 1 , figure 2 As shown, for a mine truck with a load capacity of 200 tons, the lock ring is composed of two single lock rings 1 and 2 made of 65 carbon spring steel. Among the figure, 1 and 2 are the single lock ring; 3 is the tongue cavity of the single lock ring 1; 4 is the tongue of the single lock ring 2. Such as image 3 The tongue 4 of the single-piece lock ring 2 is shown inserted into the tongue cavity 3 of the single-piece lock ring 1 . There is a gap A between the tongue 4 and the tongue cavity 3; there is a gap B between the single locking ring 1 and the single locking ring 2. Gap A and Gap B are the expansion and contraction space reserved for the lock ring, and they are also working grooves for removing the lock ring, which facilitates the installation and disassembly of the lock ring. Figure 4 The position of the lock ring is shown in the lock ring groove 5 of the rim 6 .

[0040] When the lock ring of this embodiment is installed, the...

Embodiment 2

[0042] For mining vehicles with a load capacity of 400 tons, the lock ring is composed of three single-piece lock rings made of alloy spring steel. When installing the lock ring in this embodiment, the single lock ring 1 is placed in the lock ring groove 5 first, and the tongue 4 of the single lock ring 2 is inserted into the tongue cavity 3 of the single lock ring 1 . Then insert the tongue 4 of the third single lock ring into the tongue cavity 3 of the single lock ring 2; then insert the tongue 4 of the single lock ring 1 into the tongue cavity 3 of the third single lock ring. Press the connected lock ring in the lock ring groove 5 to complete the installation of the lock ring. When the lock ring is disassembled, take out the single lock ring 1 from the lock ring groove 5 at the gap A, and then take out the single lock ring 2 and the third single block lock ring from the lock ring groove 5 in turn, and it is completed Lock ring removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com