Multifunctional LED (Light Emitting Diode) lamp based on mobile terminal control

A technology of LED lamps and LED lamps, which is applied in the direction of energy-saving control technology, lamp circuit layout, lighting device components, etc., can solve problems such as single function, not suitable for urban intelligent development, simple structure, etc., and achieve high waterproof level, Increase the effect of the vehicle detection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

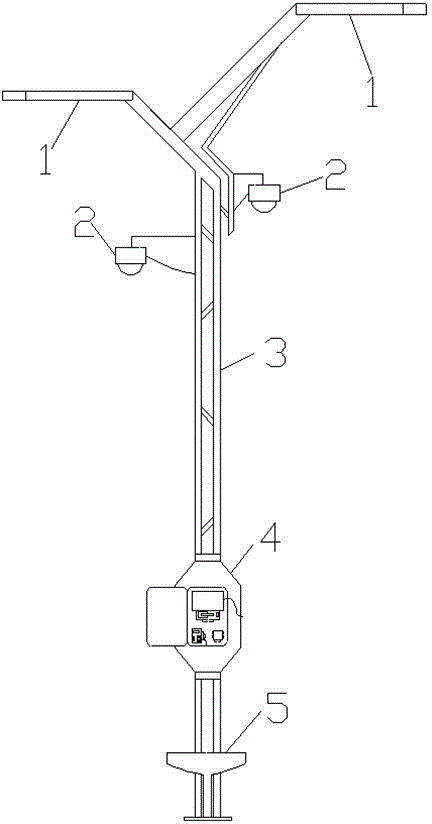

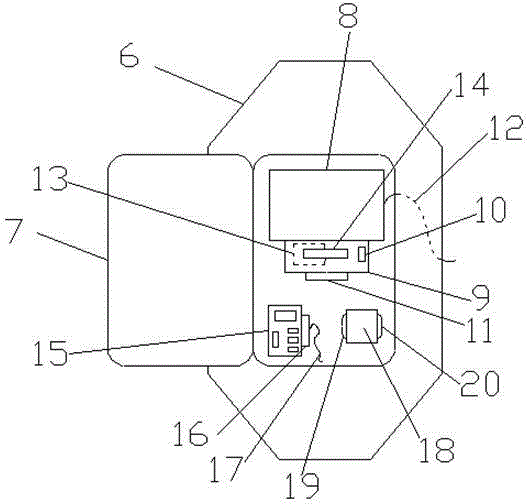

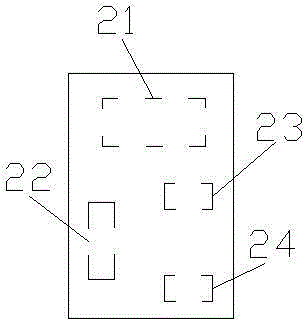

[0019] The working principle of the present invention: LED lamps are equipped with intelligent system standard interfaces, and "Lamp Intelligent Control System" can be realized through RF, Bluetooth, WiFi, 315M / 433M, ZigBee, TD-LTE and other control signals. The system is divided into software control management system There are two parts with the hardware equipment, and the software part combines the geographic information system to display the status of the lamps in a comprehensive and detailed manner, which is convenient for users to control and manage. The control system is mainly composed of two parts, one is the lighting control part; the other is the related management part. In the lamp control part, it mainly includes: automatic switch lamp setting, emergency switch lamp setting, time calibration, GPS vehicle positioning, etc.; in the lamp management part, it mainly includes: various information query, data curve chart, print report , lighting equipment management, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com