A Method of Improving the Resolution of Digital Lithography Based on Subpixel Modulation

A sub-pixel and resolution technology, applied in the direction of microlithography exposure equipment, photolithography exposure device, etc., can solve the problems of limited resolution of digital lithography technology, achieve the effect of reducing production cost and solving low resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

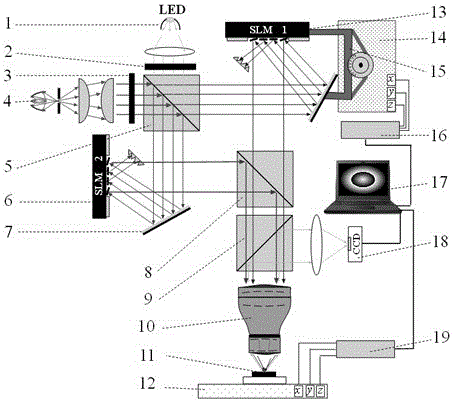

[0016] Such as figure 1 As shown, taking the reflective SLM as an example (such as DMD), the present invention is realized in this way: firstly adjust the focus of the system, close the 2# shutter 3, open the 1# shutter 2, and the light emitted by the visible light LED focusing light source 1 passes through The 1# beam splitter 5 is divided into two, and the split light reaches 1#SLM 13 and 2#SLM 6 respectively through the total reflection mirror. 1#SLM 13 and 2#SLM 6 are respectively transmitted by the computer at the same time to display different numbers mask. The light modulated and reflected by the two SLMs passes through the 2# beam splitter 8 and the 3# beam splitter 9 to reach the compacting lens 10 at the same time, and the light modulated by the 1# and 2# SLMs is compacted and imaged on the substrate 11 at the same time. The image formed on the substrate 11 is reflected by the substrate and enters the compacting lens, then enters the 3# beam splitter 9, and then is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com