Vehicle motor

A technology for motors and automobiles, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problem that the reliability of the reduction mechanism affects the service life of the starter, the uneven air gap between the rotor and the stator magnetic tile, and the impact on the service life of the automobile motor, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

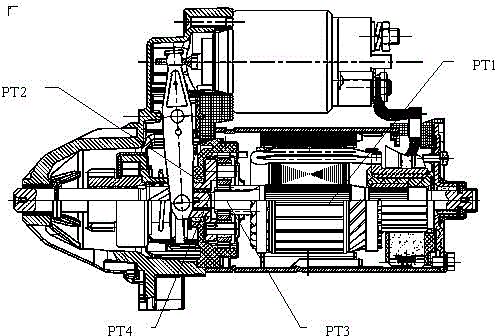

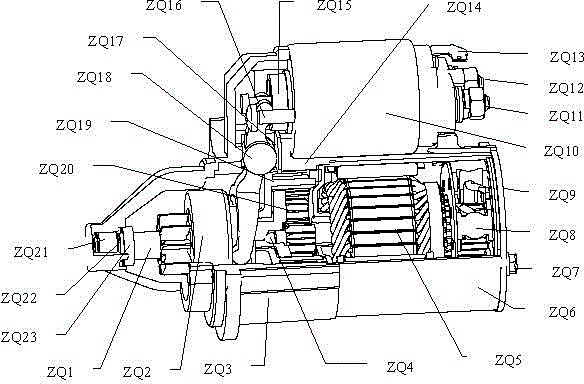

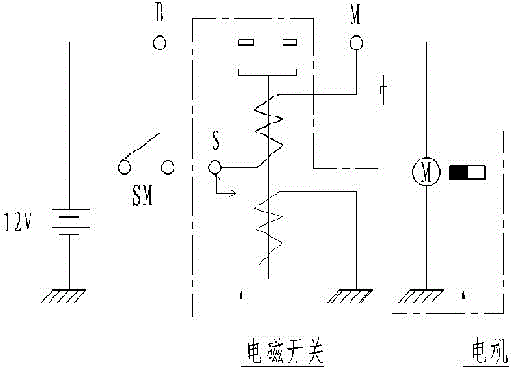

[0019] In order to improve the reliability and service life of the starter and meet the needs of the automatic start-stop technology of the automobile motor, it is urgent to invent a new type of automobile motor, which can reduce the influence of the reduction mechanism on the starter and meet the requirements of the automatic start technology. Refer below Figure 2-5 The present invention will be described in detail.

[0020] The automobile motor of the present invention is mainly made up of following parts:

[0021] --Stator assembly ZQ6: The main function is to provide a magnetic field for the motor.

[0022] --Rotor assembly ZQ5: The main function is to convert electrical energy into mechanical energy and transmit it to the planetary gear assembly ZQ20 under the action of the magnetic field of the stator assembly ZQ6.

[0023] --Brush holder assembly ZQ8: the main function is to provide a bridge for the current to enter and exit the rotor assembly ZQ5.

[0024] --Drive ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap