Preparation method of triclocarban adsorbent purifying agent

An adsorption purification agent, triclocarban technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of in-depth research on governance and short-term occurrence, and achieve adsorption Short time, convenient handling, large adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

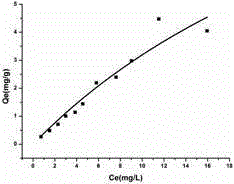

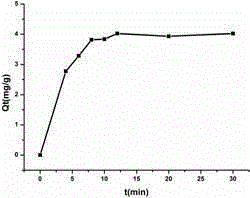

Image

Examples

Embodiment 1

[0014] Get 28.3g ferric nitrate and dissolve in 245ml deionized water to prepare a solution, set aside. Weigh La 2 o 3 16.3g in a beaker, then slowly add 29.08ml of nitric acid, after the stirring reaction is complete, pour it into a 100ml volumetric flask, and set the volume to get La(NO 3 ) 3 solution, set aside. Measure 70ml of La (NO 3 ) 3 Add the solution into the prepared ferric nitrate solution, stir magnetically, react at room temperature, slowly add 29.4g of citric acid, 7ml of ethylenediamine and 33.3g of glucose under stirring, stir for 8 hours, and then ultrasonically disperse the mixture After 20 minutes, add concentrated ammonia water drop by drop, adjust the pH to about 9.3, then dilute to 560ml, transfer to the reaction kettle, and react at 170°C for 14h. Suction filtration, wash the filter cake with deionized water and absolute ethanol, dry the filter cake at 100°C, and grind to obtain LaFeO 3 Precursor. Then calcined at 800°C for 2h to obtain LaFeO ...

Embodiment 2

[0018] LaFeO 3 The preparation is with embodiment 1;

[0019] Dissolve 3.32g of KI in 150ml of deionized water, stir magnetically, and slowly add 9.7gBi (NO 3 ) 3 ·5H 2 O and 0.0970g LaFeO 3 ;

[0020] The pH of the above mixture was adjusted to 10 with ammonia water, stirred vigorously at room temperature for 12 hours, filtered with suction, washed with deionized water until neutral, and dried at 60° C. for 6 hours to obtain a composite product.

Embodiment 3

[0022] LaFeO 3 The preparation is with embodiment 1;

[0023] Dissolve 1.7 g of KI in 75 ml of deionized water, stir magnetically, and slowly add 4.9 g of Bi (NO 3 ) 3 ·5H 2 O and 0.24g LaFeO 3 ;

[0024] The pH of the above mixture was adjusted to 10 with ammonia water, stirred vigorously at room temperature for 12 hours, filtered with suction, washed with deionized water until neutral, and dried at 60° C. for 6 hours to obtain a composite product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com