Design method of mold casting pit for vehicle-mounted mold casting steel pouring system

A design method and die-casting technology, applied in the field of metallurgy, can solve problems such as high requirements for cranes, less ingot types, and increased work load, and achieve the effects of improving the working surface of pouring steel, reducing the lifting stroke, and facilitating the production of tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

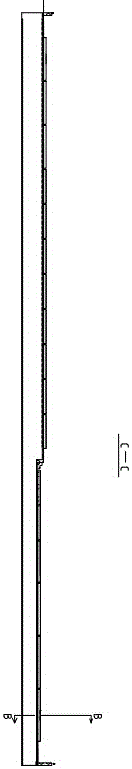

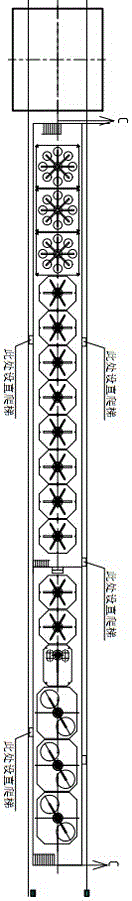

[0027] A mold casting pit design method for a vehicle-mounted mold casting steel pouring system adopts the design concept of a vehicle mold casting steel pouring pit, and arranges two mold casting steel pouring pit production lines A and B, and the two mold casting steel pouring pit production lines are respectively located in two In different spans, each die-casting steel pit is paved with a mold-casting steel-casting vehicle running track, which is convenient for the mold-casting steel-casting vehicle to pour steel. A layer of refractory bricks is laid on the inner wall and bottom of the mold-casting pit. The refractory material drying room for casting is arranged between the lines; figure 1 , 2 As shown in , 3, 4, 5 and 6, the rail gauge of the mold casting pit is designed to be 5500mm, and the inner width of the pit is designed to be 4600mm. 115mm thick refractory bricks. Pad 110mm thick sand at the bottom of the casting pit. The track model is QU120.

[0028] like i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com