Pipe end hoop welding and fixing device for automobile pipe

A technology for fixing devices and pipe fittings, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the axial processing accuracy, the deformation of automobile pipe fitting clamps, and the circumferential offset, so as to achieve reliable work, positioning and Good stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

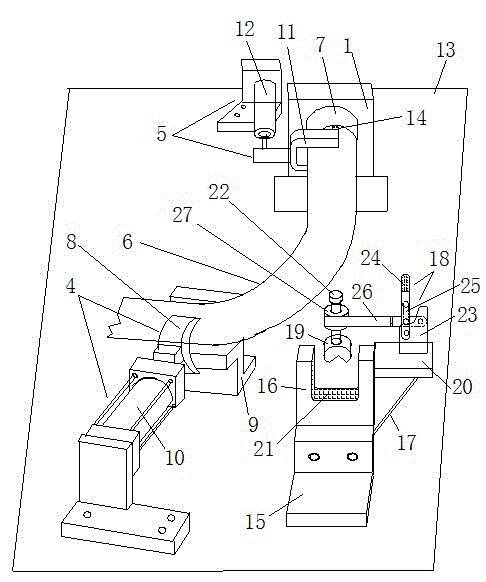

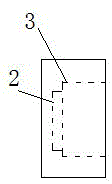

[0016] refer to figure 1 , figure 2 , propose an embodiment of the present invention, and this embodiment comprises workbench and the tube head positioning plate 1 that is fixed on the workbench, fixture, and the tube head positioning plate is provided with automobile pipe fitting limit groove 2, clip limit Groove 3, the fixture includes a side push pipe fixture 4 that presses the automobile pipe fitting 6 into the automobile pipe fitting limit groove 2, and compresses the clamp 7 that is set outside the automobile pipe fitting into the clamp limit groove 3 The hoop fixture 5 is a hoop pipe fixture 15 for clamping and positioning the automobile pipe fittings, and the positions of the three fixtures are adjustable. The working surface of the pipe fitting jaw 8 is arc-shaped, which is suitable for the shape of the automobile pipe fitting it clamps; the supporting plate is provided with an L-shaped bracket. The hoop pipe fixture 15 includes a hoop base, a bracket 16, a brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com