Rotary Tablet Press

A tablet press, rotary technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of pollution of the pharmaceutical factory environment, hydraulic oil leakage, complex structure, etc., to achieve a compact and simple structure, and ensure sealing performance, precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

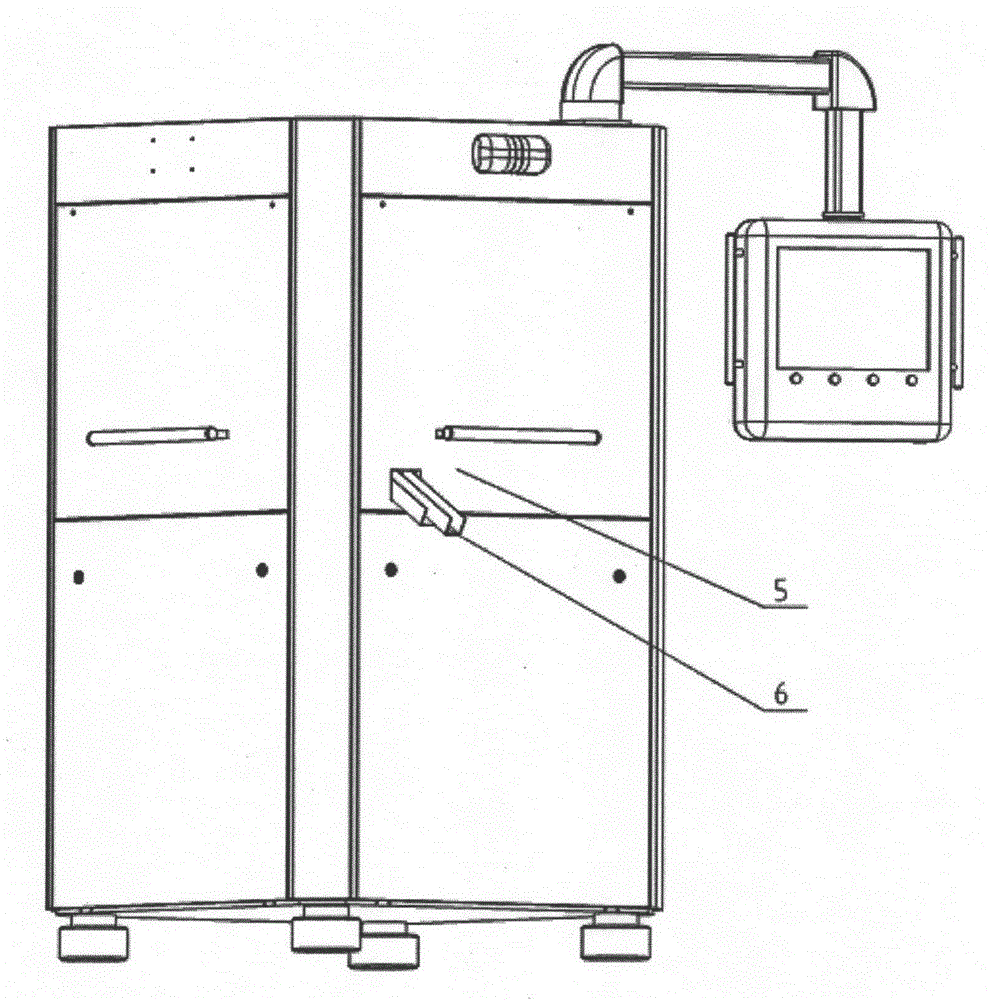

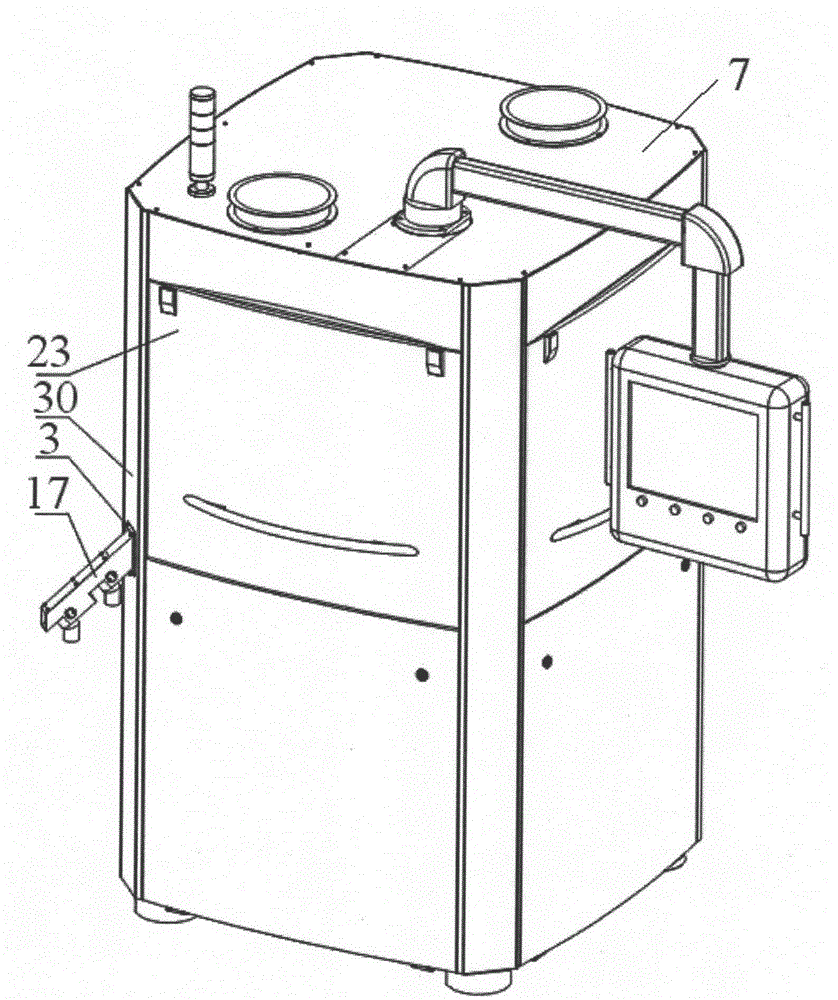

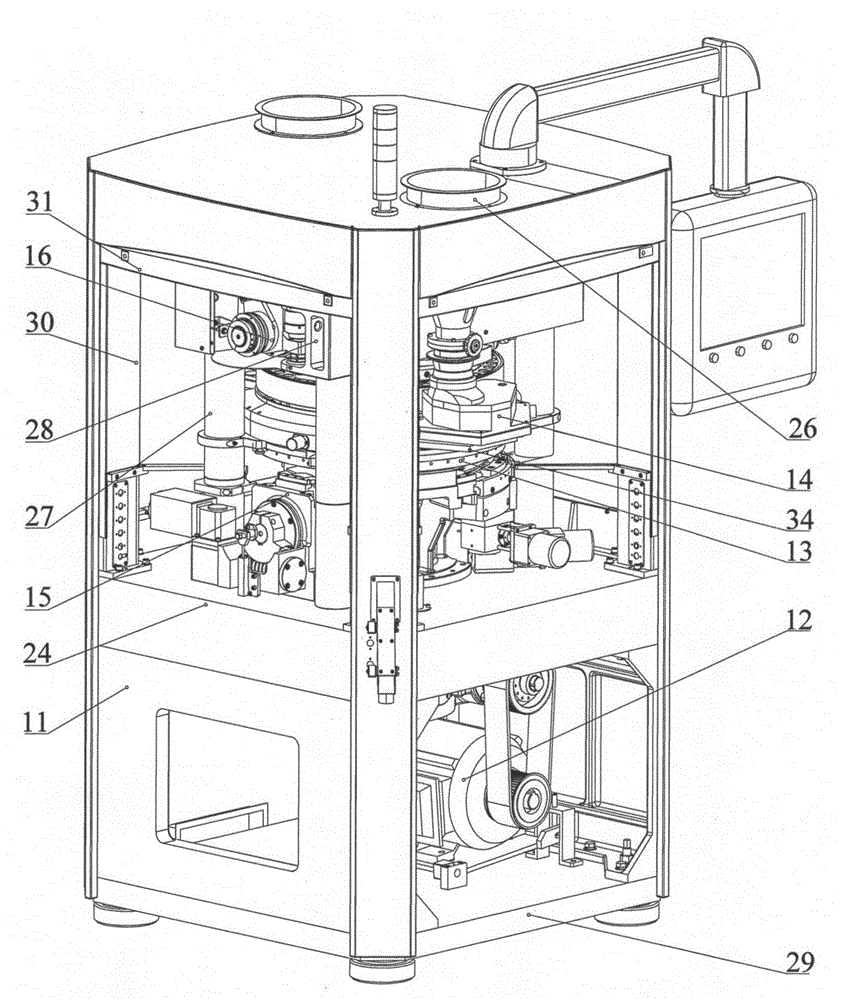

[0041] The present invention is a rotary tablet press, such as Figure 2-Figure 6As shown, it includes the frame 7 of the tablet press, and the frame 7 is composed of a bottom plate 29, a wall plate 11, a middle plate 24, an outer frame column 30 and an upper frame 31. The main transmission 12 is installed on the lower part of the frame 7 (between the middle plate 24 and the bottom plate 29). The lower main pressure roller device 15 is installed on the middle plate 24 . Four column covers 27 are fixed on the middle plate 24 and support the upper roller frame 28 . The upper main pressure roller device 32 is fixed on the upper pressure roller frame 28 , and the pressure sensor overload protection device 16 is connected with the upper main pressure roller device 32 . The main bearing housing 25 is installed on the middle plate 24 . The lower track device 18, the filling device 33 and the lower pre-compression wheel device 20 are all installed on the main bearing housing 25. T...

Embodiment 2

[0057] In this embodiment, the quick assembly and disassembly film output device 17 is a quick assembly and disassembly double slot film output device.

[0058] like Figure 10 Shown, it is divided into double groove fixed groove body 17-10 and double groove movable groove body 17-9 two parts. like Figure 9 As shown, one end of the double-groove fixed tank body 17-10 is connected with the inner column 17-4 by the tank body support 17-6, and the other end of the double-groove fixed tank body 17-10 is inserted into the double-groove movable tank body 17-9. One end is overlapped, and the other end of the double-slot movable tank body 17-9 passes through the outer frame column 30 and is fixed on the outer wall of the outer frame column 30 by four knurled small-head screws 3 . The end of the double-slot fixed tank body 17 - 10 connected to the tank body support 17 - 6 is located at the edge of the turntable 13 .

[0059] like Figure 12 As shown, the double-groove fixed groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com