Aircraft

An aircraft and machine arm technology, applied in the field of aircraft, can solve the problems of weak stability of the aircraft 100, and achieve the effects of high safety and reliability, increased pulling force, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

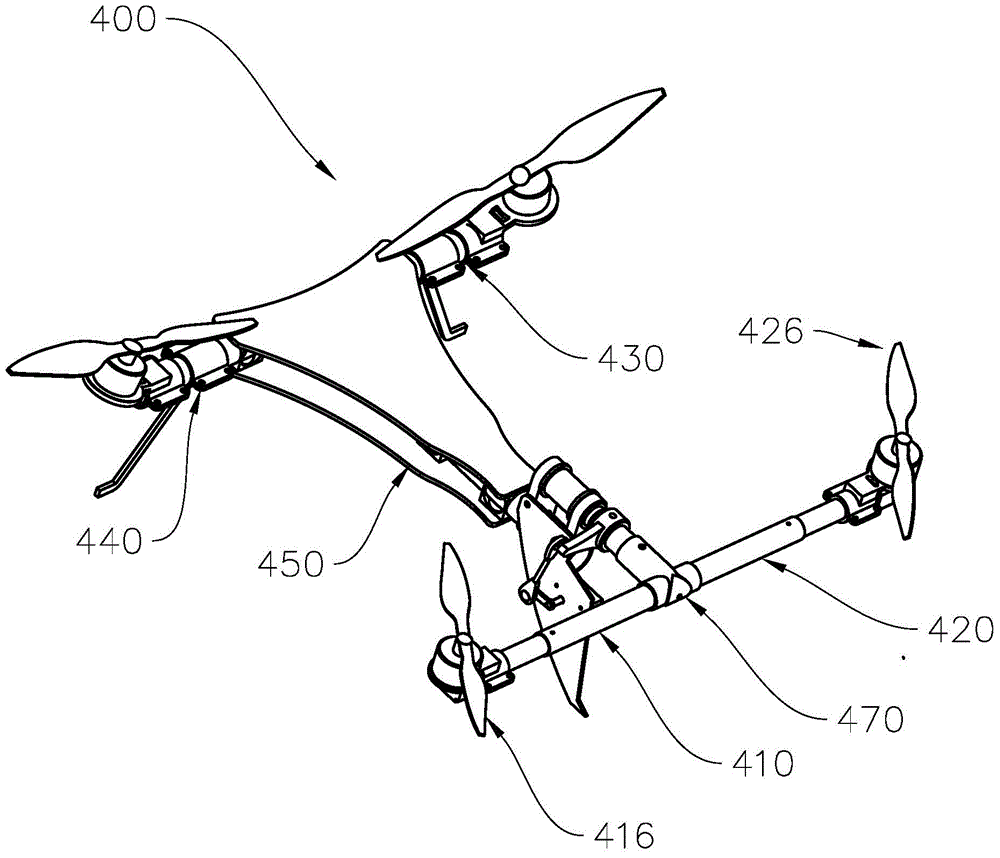

[0043] Such as image 3 , Figure 4 and Figure 5 As shown, the I-shaped aircraft 400 has a frame 450, and the frame 450 has a first arm device, a second arm device, a first T-shaped tee 470, a first rotating shaft 460 and a first rotating power unit.

[0044] The first arm device has a first sub-arm 410 and a second sub-arm 420, the outer end of the first sub-arm 410 has a first rotor 416, and the outer end of the second sub-arm 420 has a second rotor 426. The second arm has a third sub-arm 430 and a fourth sub-arm 440 . The first T-shaped tee 470 has a first horizontal tube 471 and a first vertical tube 473 . The first rotary power unit includes a motor 465 , a crank 461 , a transmission rod 462 , and a rocker arm 463 connected in sequence. One end of the rocker arm 463 is fixedly sleeved on the first rotating shaft 460 .

[0045] The first sub-arm 410 and the second sub-arm 420 are symmetrically distributed on both sides of the first rotating shaft 460 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com