TPE composition and high performance antibacterial medical tourniquet prepared from TPE composition

A composition and modification technology, applied in bandages, medical science, absorbent pads, etc., can solve the problems of expensive nano-silver, poor dispersion of nano-silver, and decreased antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Another aspect of the present invention provides the preparation method of high-performance antibacterial medical tourniquet, comprising the following steps:

[0065] (1) The TPE composition is extruded and granulated by twin-screw;

[0066] (2) Vacuum injection molding the product obtained in step (1) into a mold at 170° C. to 200° C., and maintain the injection molding temperature for 8 hours under vacuum conditions, and then cool and solidify.

[0067] The applicant unexpectedly found that the cross-linking density of the tourniquet can be further increased by vacuum injection molding and maintaining high temperature under vacuum conditions. This is because graphene oxide contains a large number of carboxyl groups, which can undergo Friedel-Crafts acylation reaction with the benzene ring on the styrene unit in SEBS and MAH-g-SEBS under high temperature and vacuum dehydration conditions, thereby further cross-linking. Linked to provide the beneficial technical effect...

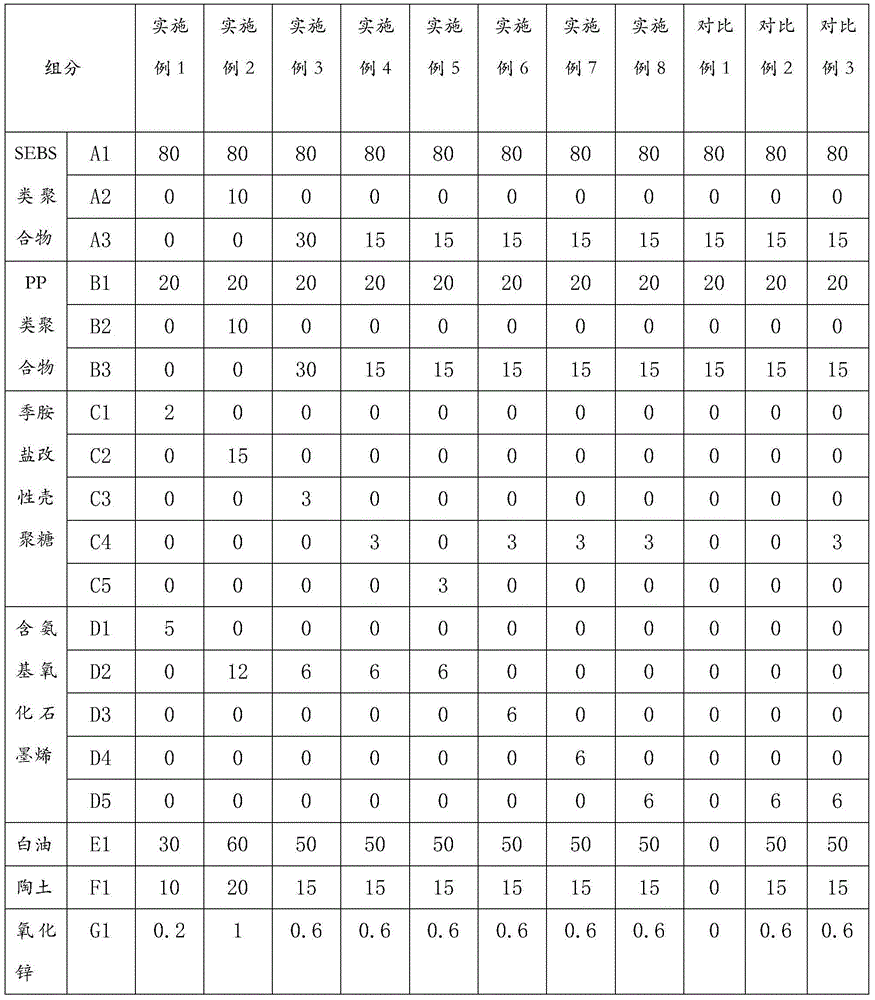

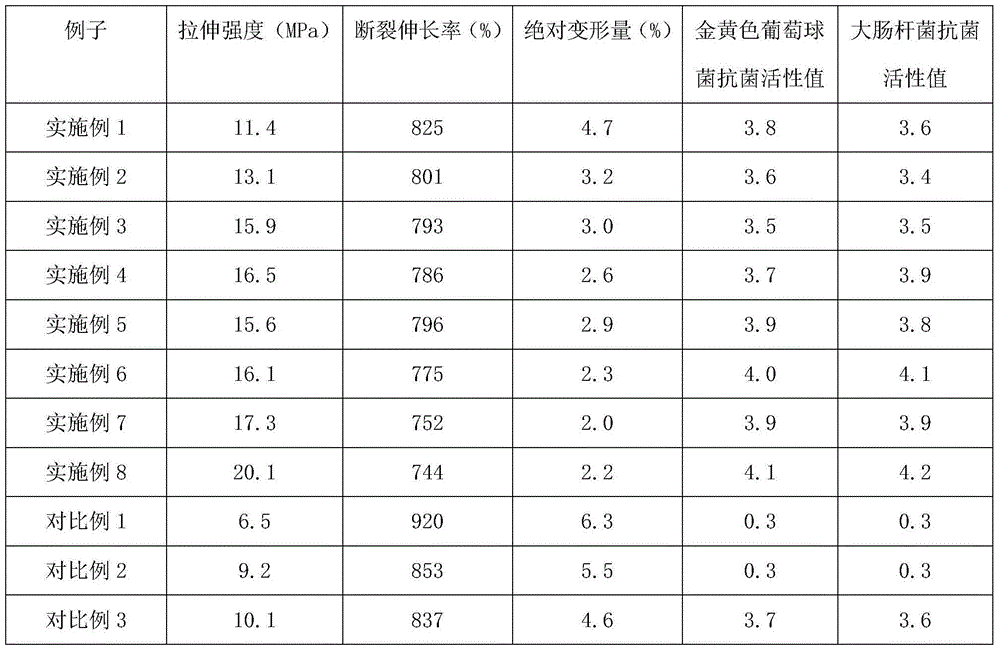

Embodiment 1~8 and comparative example 1

[0091] Prepare high-performance antibacterial medical tourniquet according to the formula in the following table, and the preparation method is as follows (the consumption of following components is all parts by weight):

[0092] (1) After mixing the raw materials by weight, granulate through twin-screw extrusion;

[0093] (2) Vacuum injection mold the product obtained in step (1) into a mold at 195° C., keep the temperature under vacuum for 8 hours, and then cool and solidify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com