Series furnace device for reducing distillation and production of titanium sponge

A titanium sponge and reactor technology, applied in the field of series furnace devices, can solve problems such as obvious gaps, achieve the effects of reducing tank cost, flexible handling of faults, and simplifying tank structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

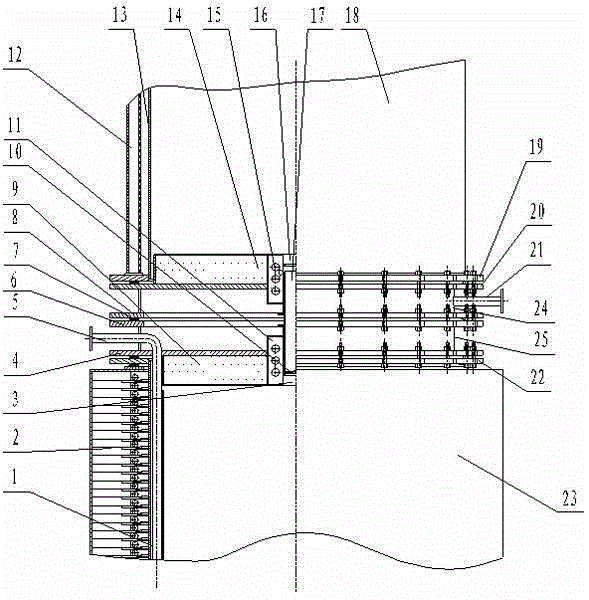

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

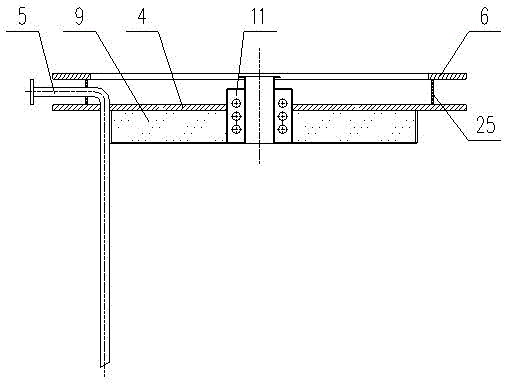

[0025] Such as figure 1 , figure 2 As shown, a tandem furnace device for the reduction distillation production of sponge titanium is mainly composed of a condenser 18 and a reactor 23 . The structures of the condenser 18 and the reactor 23 are exactly the same, and the two can be used interchangeably. The condenser 18 and the reactor 23 are connected up and down in an I type.

[0026] The reactor 23 is composed of a tank body and a large cover connected by flange rubber pads and bolts. The tank body mainly includes: the reactor tank body 1 and the reactor tank body flange 22; the large cover includes: the central tube of the reactor large cover 3. The lower flange of the large reactor cover 4, the upper flange of the large reactor cover 6, the thermal insulation layer of the large reactor cover 9, the inner heater 11 of the large reactor cover, and the magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com