Comparison of construction method between the design load of the roof of the underground garage and the load of engineering vehicles

A technology for engineering vehicles and underground garages, which is applied in the field of comparison between the design load of the roof of the underground garage and the load of engineering vehicles, can solve problems such as the increase of comprehensive construction costs and construction period, the impact of construction progress and economic benefits, and the reduction of concrete pouring efficiency. Reduce block loss and construction waste, reduce concrete waste and construction waste, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

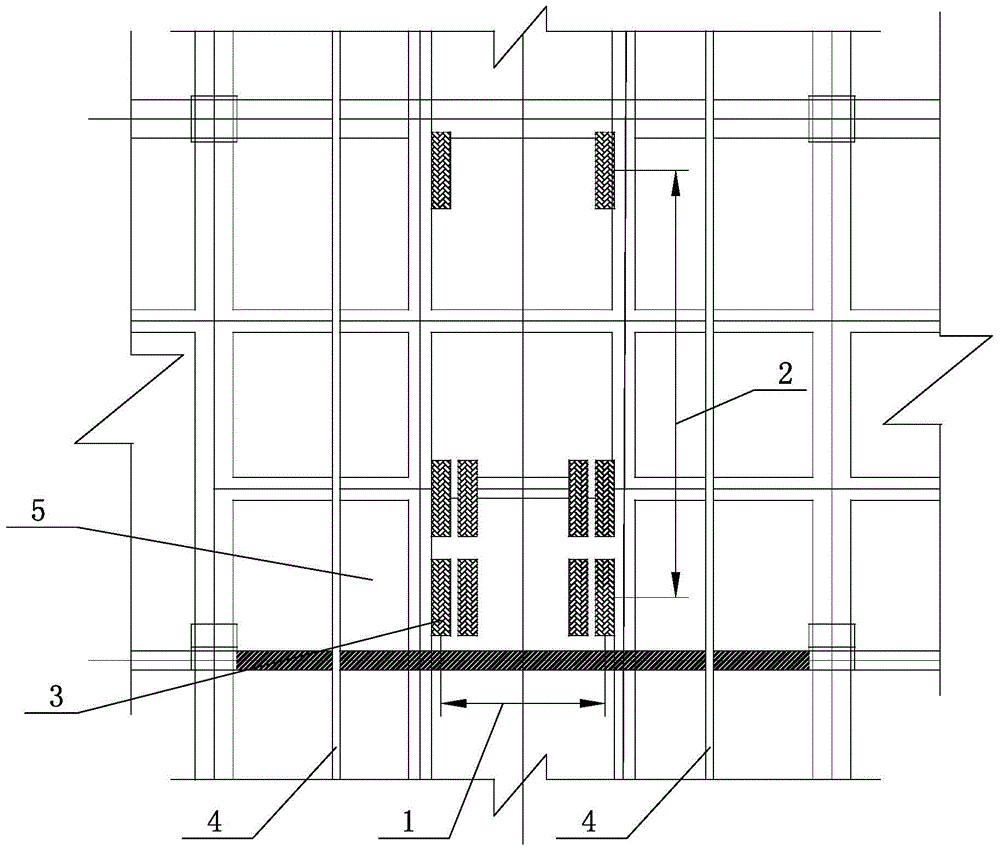

[0066] The present invention will be further described below in conjunction with accompanying drawing:

[0067] Such as figure 1Shown, the underground garage roof design load of the present invention and engineering vehicle load contrast construction method, take the following steps:

[0068] 1. Calculation of the allowable load design value of the roof of the underground garage

[0069] 1) Overview of implementation cases

[0070] A. After the construction of the main building of a project plan is completed, the sub-item construction of the roof 5 of the underground garage will be carried out;

[0071] B. The roof reinforcement of the underground garage is HRB400 double-layer two-way φ10@150, the thickness of the stress reinforcement protective layer is 15㎜, the concrete strength grade is C30, the thickness of the cast-in-place slab is 180㎜, the upper design covering soil thickness is 1.5m, and the allowable live load standard value 5KPa;

[0072] C. It is planned to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com