PCA-FIG-SVM (Principal Component Analysis-Fuzzy Information Granulation-Support Vector Machine)-based absolute gas emission prediction method

A technology of PCA-FIG-SVM and prediction method, which is applied in the fields of gas discharge, earth cube drilling, mining equipment, etc., and can solve the problems of not considering mining conditions, lack of monitoring data development trend, uncertainty of gas emission, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

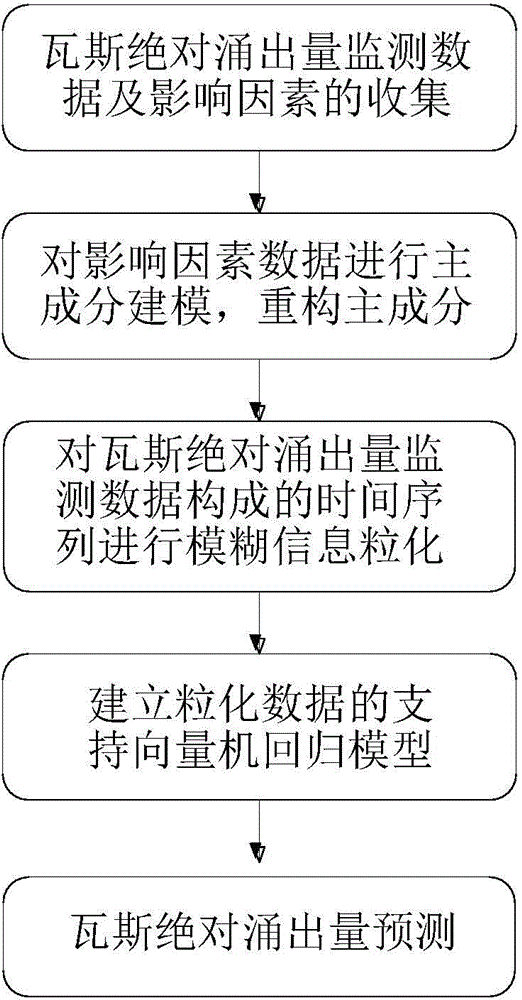

[0041] Such as figure 1 As shown, the absolute gas emission prediction method based on PCA-FIG-SVM includes the following steps:

[0042] (1) Collection of absolute gas emission monitoring data and influencing factors; among them, influencing factors include coal seam thickness, coal seam gas content, coal seam spacing, daily advancing speed and daily average production.

[0043] (2) Carry out principal component modeling on the influencing factor data, and reconstruct the principal components. The specific steps are as follows

[0044] ① Normalize the influencing factor data to obtain the sample set matrix X;

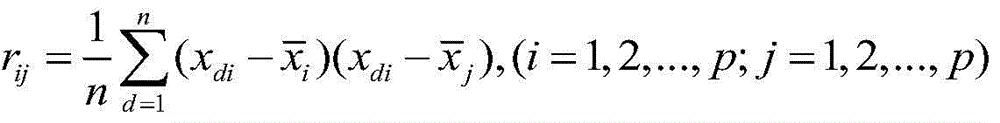

[0045] ② Transform the sample set matrix X into a correlation matrix using the following formula to obtain the principal component matrix R:

[0046] R=(r ij ) p×p

[0047] and r ij = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com