Thermal load control system and method for high-pressure direct injection injector in cylinder with micro-diesel pilot ignition

A control system and injector technology, which is applied in fuel injection devices, charging systems, machines/engines, etc., can solve problems such as high heat load and injector burnout, so as to prevent excessive temperature, improve reliability, and overcome Effects of excessive heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

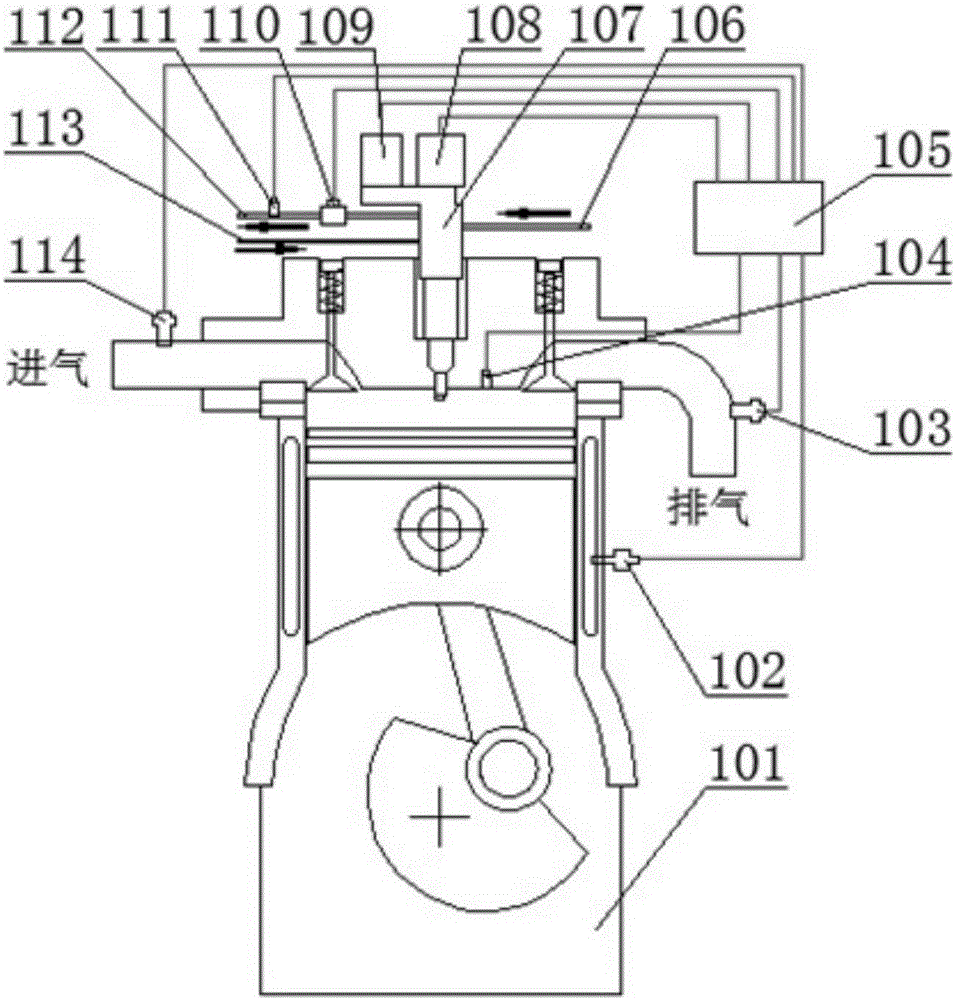

[0034] figure 1 A specific embodiment of a thermal load control system for a micro-quantity diesel pilot in-cylinder high-pressure direct injection injector is given, including:

[0035] Engine 101, engine temperature sensor 102, exhaust temperature sensor 103, cylinder temperature sensor 104, electronic control system ECU 105, high-pressure natural gas supply pipeline 106, diesel / natural gas injector 107, natural gas injection control solenoid valve 108, diesel injection control solenoid Valve 109, cooling diesel oil volume control valve 110, diesel oil return sensor 111, diesel oil return pipeline 112, high pressure diesel oil supply pipeline 113 and intake air flow sensor 114;

[0036] Electronic control system ECU105, natural gas injection control solenoid valve 108, diesel injection control solenoid valve 109, cooling diesel oil quantity control valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com