Outgoing cable twisting-off prevention device of miniature horizontal shaft wind generating set

A technology for wind turbines and cables, which is used in wind turbines, wind power generation, engines, etc., can solve the problems of spring elastic force not recovering in time, wind turbine failure, insulation material burning and other problems, so as to overcome arc burning, Low production cost and the effect of preventing from being twisted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

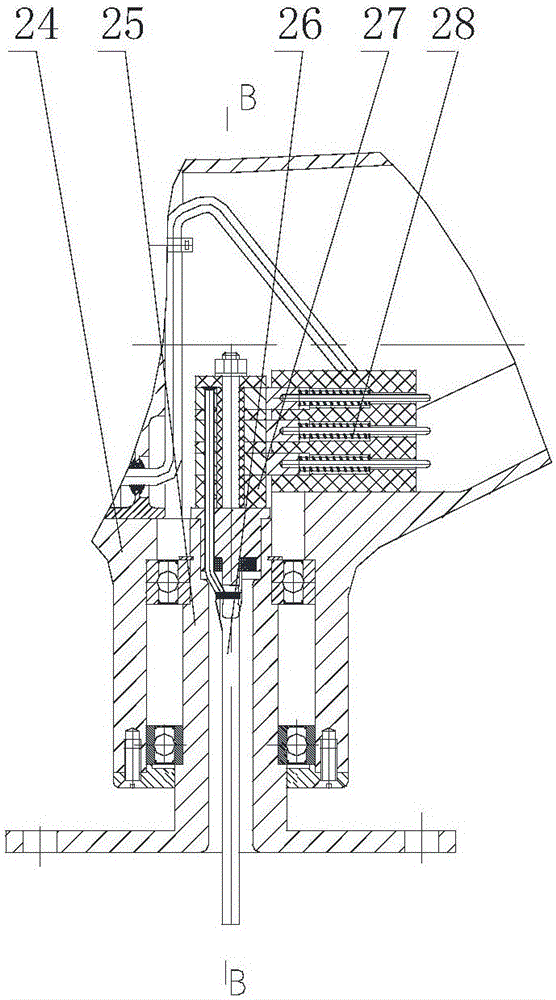

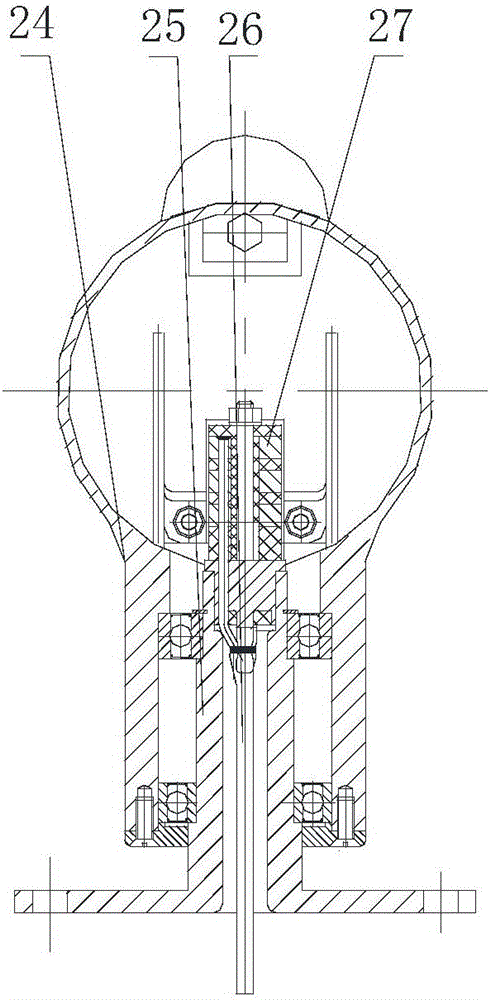

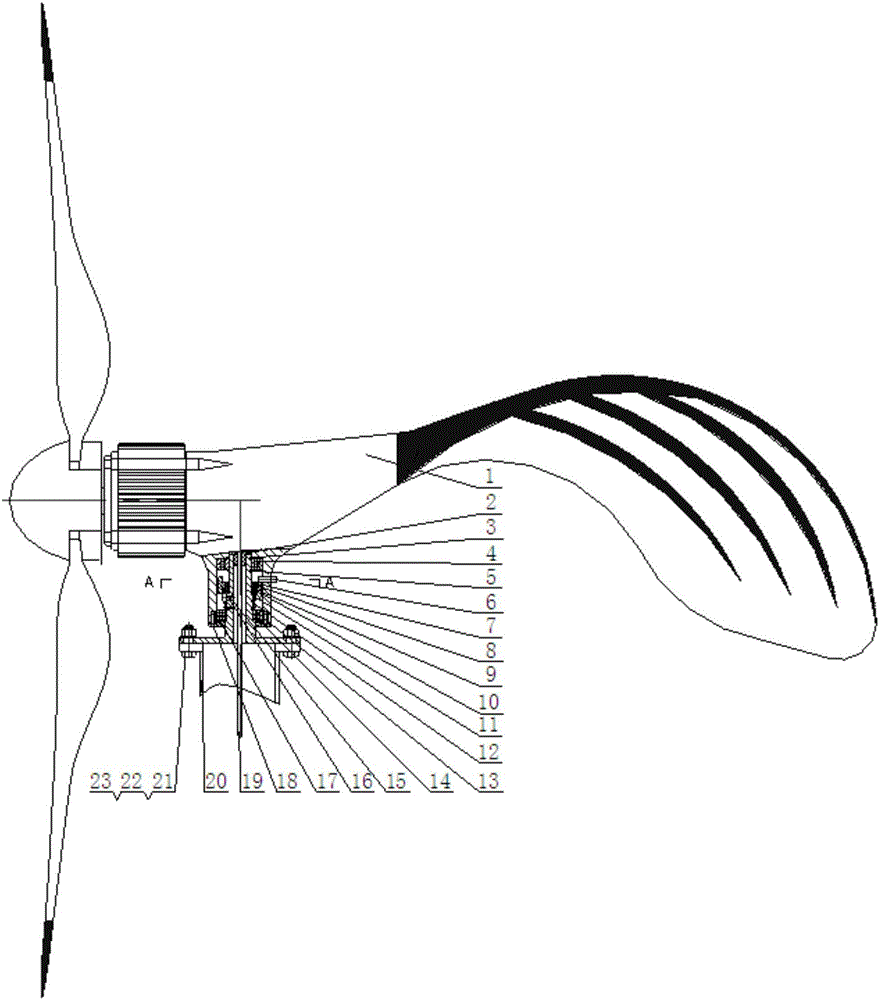

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 3 to 5 As shown, the present invention includes the fan body 1 as the base body, the bearing cover 17 is placed under the supporting shaft 12, the lower sealing bearing 14 and the supporting shaft 12 are combined in interference, and the lower sealing bearing 14 is axially connected by the third retaining ring 13. direction limit; install and combine the torsion spring 11 and the support shaft 12, and at the same time, one end of the lower end is fitted into the hole of the support shaft 12 with an interference fit, and the limit piece 15 is installed and combined with the support shaft 12; Insert the lower ring 7, and then install and combine its assembly with the support shaft 12 interference, and at the same time insert the upper end of the torsion spring 11 into the hole of the lower ring 7, and set the spacer ring 9 on the support shaft 12; the upper bearing 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com