Method and energy storage and release device for restarting compressor by using energy stored during shutdown of compressor

A technology of releasing device and energy storage, applied in the direction of machine/engine, engine, mechanical equipment, etc., can solve the problems of increased heat generation of rotor winding, influence of motor insulation, limited starting torque, etc., to reduce the starting time, The effect of protecting compressor motor, reducing starting current and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing and embodiment, but present embodiment is not intended to limit the present invention, and all similar structures of the present invention and similar changes thereof are included in the scope of protection of the claims of the present invention.

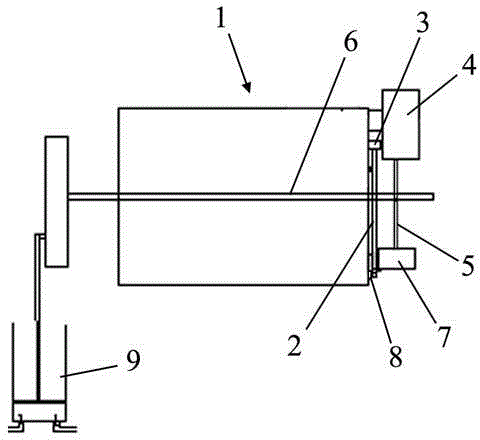

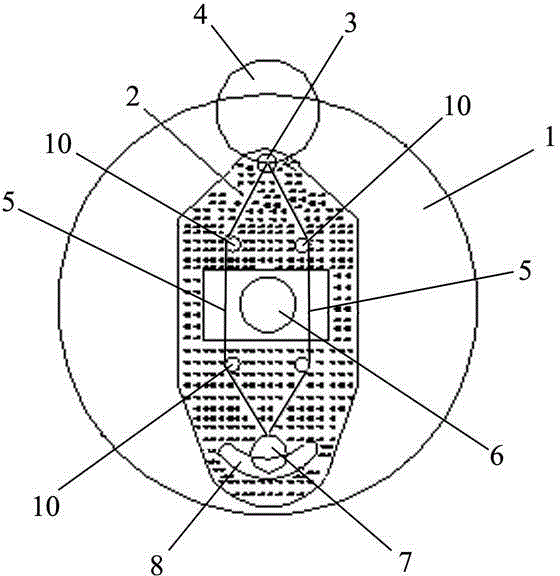

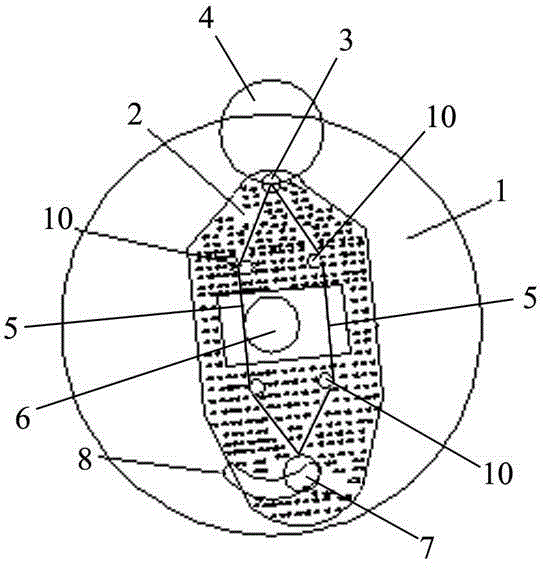

[0020] An energy storage and release device that utilizes compressor stop energy storage to restart, such as figure 1 As shown, one end of the motor rotor 6 of the compressor 1 is connected to the compressor cylinder 9 to drive the compressor 1 to move compressed gas, and the other end of the motor rotor 6 is connected to a scroll spring energy storage device to stop the compressor 1 When the kinetic energy is converted into elastic potential energy and stored in the scroll spring, the scroll spring energy storage device 4 releases the elastic potential energy in the scroll spring to convert it into the kinetic energy of the compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com