Pre-stressed steel cylinder concrete conveying pipe used for ferrous nitrate

A technology of concrete conveying pipe and prestressed steel, which is applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of increased steel consumption, concrete falling off, and increased steel pipe weight, and achieves the effect of providing conveying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

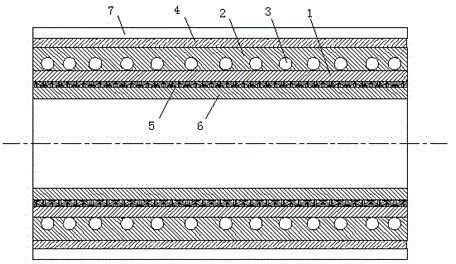

[0012] The prestressed steel cylinder concrete delivery pipe for ferrous nitrate includes a base pipe 1, the outer wall of the base pipe 1 is provided with a concrete layer 2, and the concrete layer 2 is provided with a circumferentially wound prestressed steel wire 3, and the concrete layer 2 is also coated with The cement slurry sand layer 4, the inner wall of the base pipe 1 is provided with a pure zinc coating 5, the pure zinc coating 5 is coated with a plastic coating layer 6, and the plastic coating layer 6 is epoxy resin, and the plastic coating layer 6 The thickness is 10~20mm. Epoxy resin is sprayed on the hoop-wound prestressed steel wire 3 . The cement slurry sand layer 4 is provided with an epoxy coal tar pitch anticorrosion layer 7 outside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com