Prediction module and test method for motor vibration characteristics under working state

A technology of working state and vibration characteristics, applied in motor generator testing, vibration measurement in solids, measurement of vibration, etc., can solve problems such as not involved in the study of vibration characteristics of motor working state, and achieve a simple and efficient implementation process, comprehensive consideration, Simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Taking the working state of a certain large motor as an example, the present invention will be further described in conjunction with the accompanying drawings:

[0030] 1. Hardware structure.

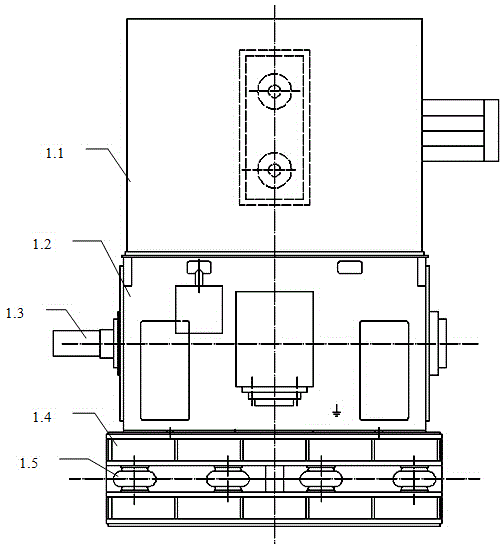

[0031] Such as figure 1 Shown, include in the prediction module of the present invention:

[0032] A motor modeling unit: constructed based on a solid motor, the motor model is mainly assembled from cooling system 1.1, stator 1.2, rotor 1.3, base 1.4 and vibration-damping airbag 1.5;

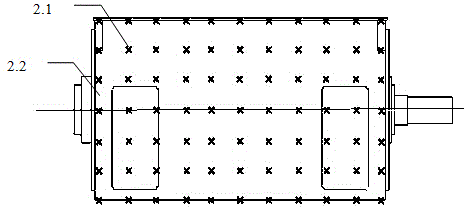

[0033] Such as figure 2 As shown, the acceleration sensor 2.1 is arranged on the motor casing 2.2 in the vibration characteristic test under the working state of the motor of the present invention, and is distributed in a 30×30cm rectangular array;

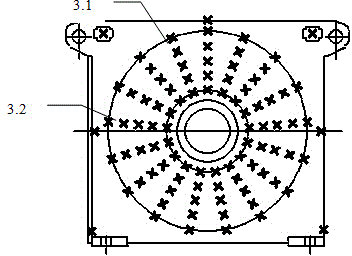

[0034] Such as image 3 As shown, in the vibration characteristic test of the motor in the working state of the present invention, the acceleration sensor 3.1 is arranged on the motor end cover 3.2, and according to concentric circles with a diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com