Online monitoring and fault-diagnosing device of main fan for mines

A fault diagnosis device and ventilator technology, applied in mining equipment, mine/tunnel ventilation, mining equipment, etc., can solve the problems of signal processing and control being easily interfered by the outside world, poor anti-interference ability and use stability, and increased costs , to achieve the effect of simple structure, improved comprehensive performance and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

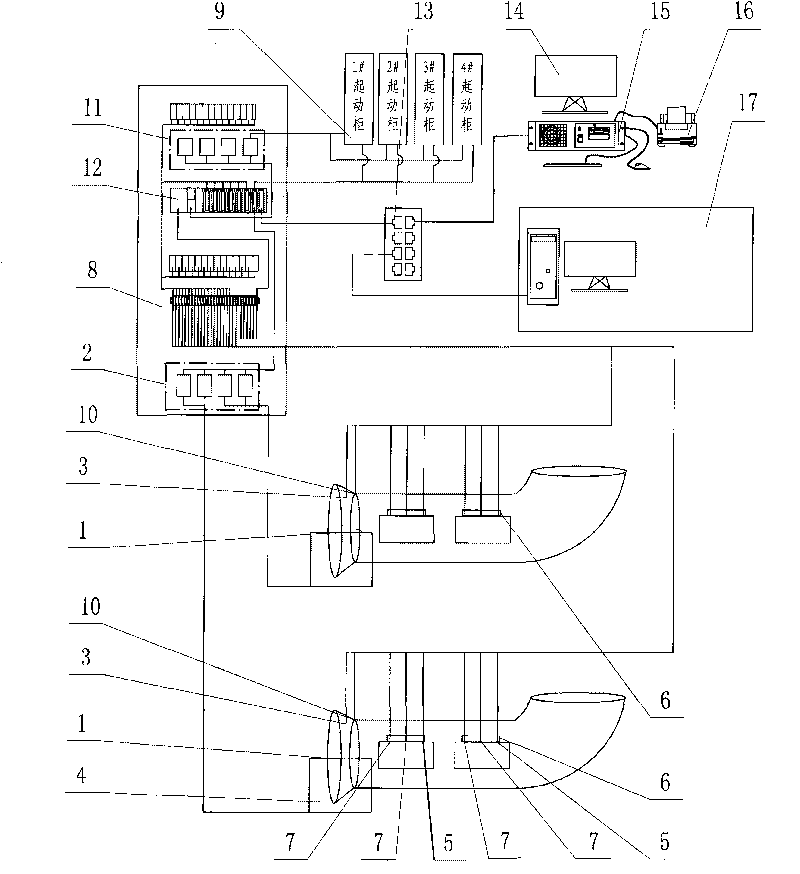

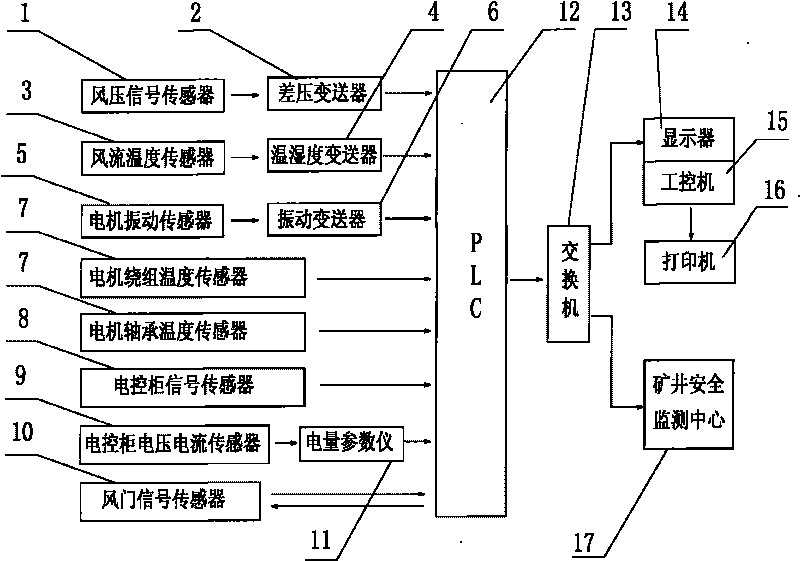

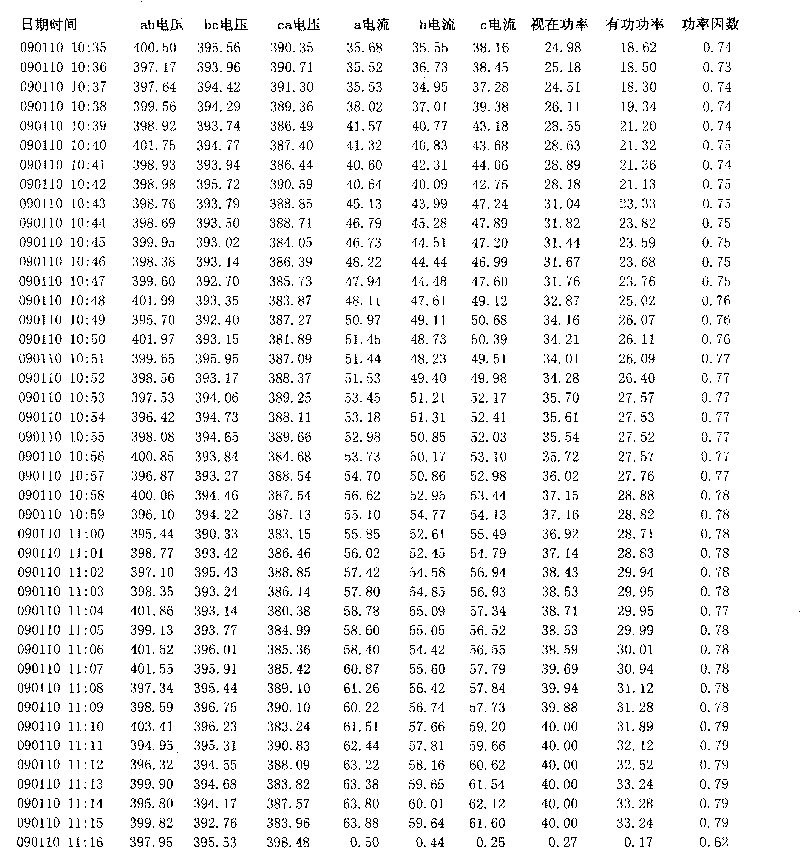

[0025] By the attached drawing figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an on-line monitoring and fault diagnosis device for a mine-used main ventilator includes a wind pressure signal sensor 1 installed at the air outlet of the main ventilator, connected to the PLC12 via a differential pressure transmitter 2, and the wind pressure signal sensor 1 measures and collects the fan The pressure at rest and the air flow pressure when the fan is running are processed by the differential pressure transmitter 2 and converted into electrical signals, which are sent to the PLC12 for logic control. The PLC12 sends the processed signals to the interface of the display 14 through the switch 13. The air flow static pressure is set to 160-1280Pa, and the air flow total pressure is set to 360-1500Pa. When the air flow pressure is too high or too small, the upper and lower limit values are automatically verified through online monitoring, and the table is automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com