Method for producing silicon-containing aluminum alloy ingot

一种制造方法、铝合金的技术,应用在铝合金铸块的制造领域,能够解决不能除去磷、过滤器堵塞等问题,达到除去操作容易、防止堵塞、提高生产率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Specific examples of the present invention will be described below, but the present invention is not particularly limited to these examples.

[0063]

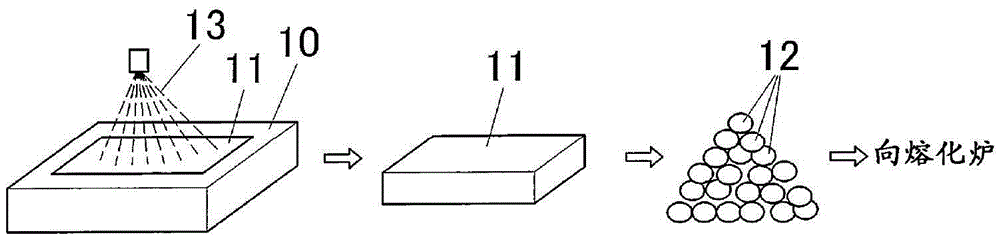

[0064] A silicon ingot (with a phosphorus content of 230 ppm) obtained by reducing silica was heated and melted, and the resulting melt was poured into a mold 10 and allowed to cool naturally to obtain a rectangular parallelepiped silicon ingot 11 . Through this natural cooling, the solidification of the molten silicon proceeds from the vicinity of the outer peripheral frame portion of the mold and completes the solidification at the upper exposed surface. like figure 1 As shown, the upper surface of the ingot 11 (finally solidified part) was sprayed with water 13 at 20° C. for 30 minutes in a state where the silicon ingot 11 was left in the mold 10 .

[0065] Next, a rectangular parallelepiped silicon ingot 11 is taken out from the mold 10, and after drying to remove attached water, the silicon ingot is disintegrated...

Embodiment 2

[0068] A silicon ingot (with the same phosphorus content as that of the silicon ingot used in Example 1) obtained by reduction treatment of silica was heated and melted, and the resulting melt was poured into the mold 10, allowed to cool naturally, A rectangular parallelepiped silicon ingot 11 was obtained. Through this natural cooling, the solidification of the molten silicon proceeds from the vicinity of the outer peripheral frame portion of the mold and completes the solidification at the upper exposed surface.

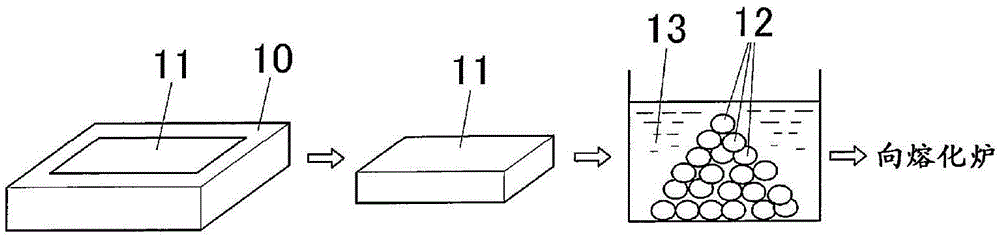

[0069] Then, as image 3 As shown, a rectangular parallelepiped silicon ingot 11 is taken out from a casting mold 10 , and the silicon ingot is disintegrated to obtain a plurality of disintegrated products 12 . Then, a water washing process of immersing the plurality of crushed products 12 in water 13 at 90° C. for 10 minutes was performed. Next, after removing the adhered water from the disintegrated products 12 taken out by drying, these disintegrated products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com