Automatic temperature-control electronic cigarette with titanium wire

An automatic temperature control and electronic cigarette technology, applied in tobacco, smoker's products, applications, etc., can solve problems such as obstacles to the development of electronic cigarettes, damage to the health of users, inability to accurately control the heating temperature of the atomizing wire, and achieve a good market. Development prospects and the effect of reducing the generation of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

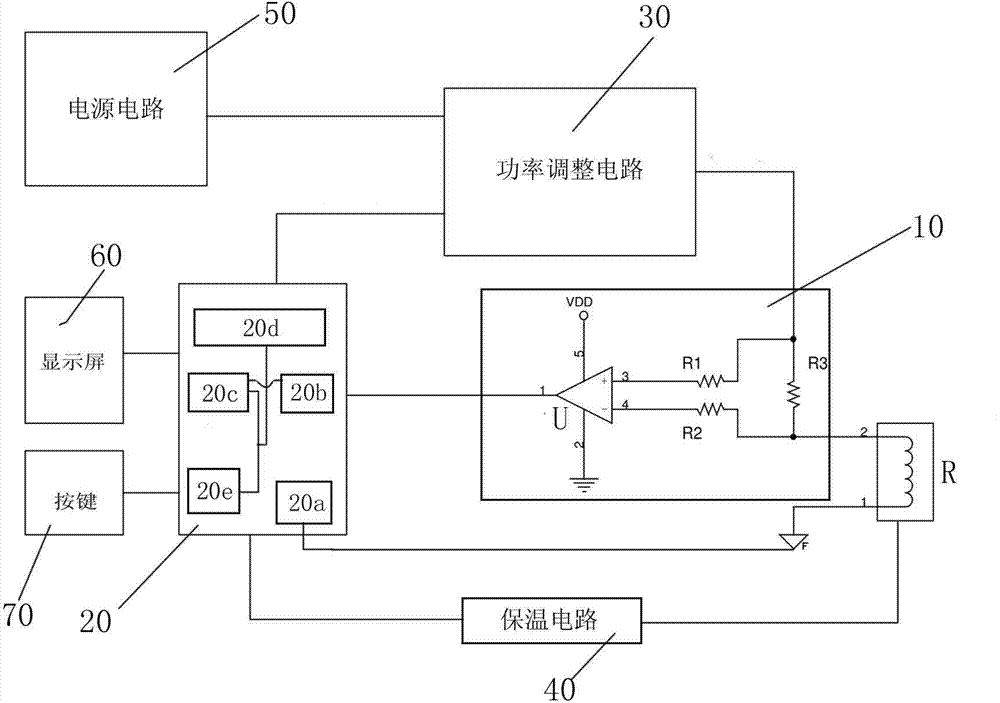

[0028] Such as figure 1 As shown, the present invention provides an automatic temperature control titanium wire electronic cigarette, including an atomizing wire R, a sampling circuit 10 connected in series with the atomizing wire R, a single-chip microcomputer 20 connected to the output end of the sampling circuit 10, and a single-chip microcomputer 20 connected to the The power adjustment circuit 30 and the heat preservation circuit 40 controlled by the single-chip microcomputer 20, the power supply circuit 50 connected with the power adjustment circuit 30, the display screen 60 and the button 70 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com