A High Frequency Fluttering Cold Extrusion Die

A cold extrusion and flutter technology, used in metal extrusion dies, fluids using vibration, etc., can solve the problems of unpredictable and controllable amplitude and frequency, single vibration mode, etc., to achieve diverse vibration modes, vibration frequency and amplitude. Precisely controllable value, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

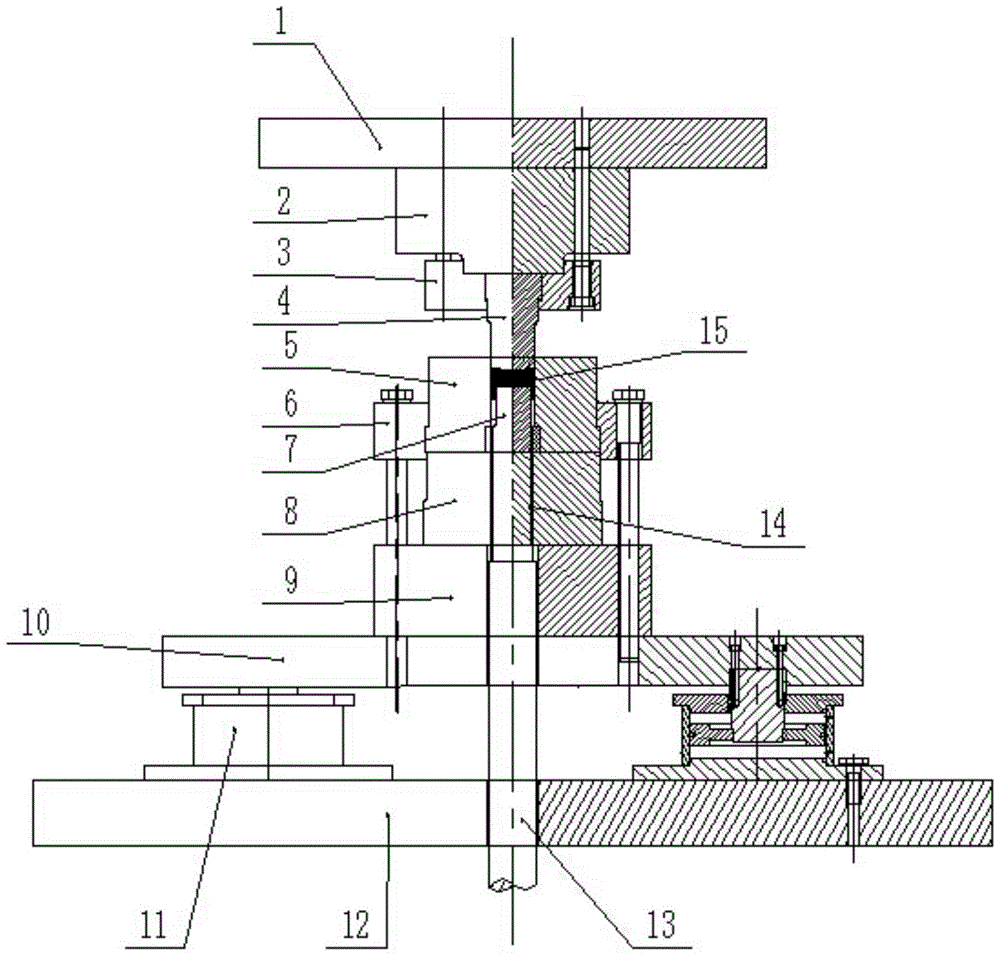

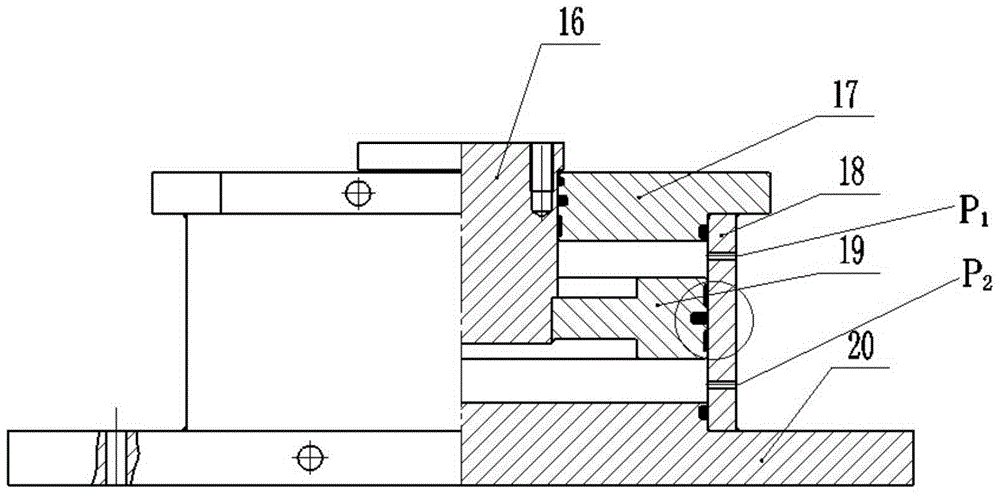

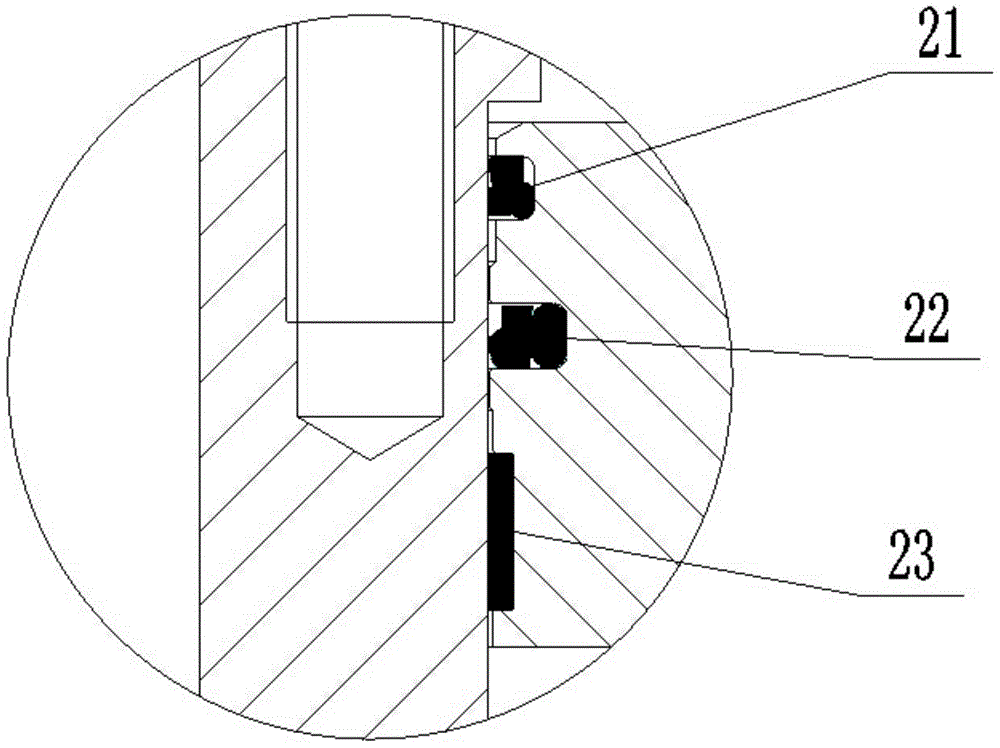

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] refer to Figure 1 to Figure 6 , a high-frequency chattering cold extrusion die, including a molding mechanism and a chattering mechanism, the molding mechanism includes an upper template 1, a punch flange connection block 2, a punch fixing block 3, a punch 4, a die 5, a lower Punch 7, die fixing block 6, die base 8, die flange connection block 9, lower template 10, ejector sheet 14, ejector rod 13, punch 4 is installed in punch fixation block 3, and the punch The mold fixing block 3 is connected with the punch flange connection block 2 directly above and the upper template 1 through bolts, the die 5 located directly below the punch 4 is installed in the die fixing block 6, and the die 5 is connected with the die directly below The seat 8 is in contact, the die seat 8 is in contact with the die flange connecting block 9 directly below, and the die fixing block 6, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap