Method for preparing Eprosartan impurity EP12A

A kind of eprosartan, EP12A technology, applied in the field of medicinal chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

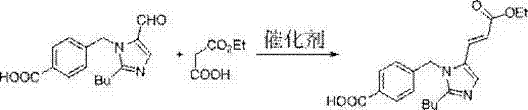

Image

Examples

Embodiment 1

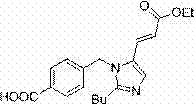

[0019] Synthesis of (E)-4-[[2-butyl-5-(2-ethoxycarbonylvinyl)imidazol-1-yl]methyl]benzoic acid [impurity EP12A]:

[0020] To a 500 mL three-neck flask, add 28.6g (0.10 mol) 4-[[(2-butyl-5-formyl) imidazol-1-yl] methyl] benzoic acid, 26.4g (0.20 mol) Monoethyl malonate, 150g toluene, 1.74g (0.02 mol) morpholine, started stirring, raised the temperature to reflux, separated water, and reacted for 12h. The reaction solution was concentrated under reduced pressure, and then purified by column chromatography to obtain 30.0 g of white solid, HPLC purity: 98%, yield: 84.3%. 1 H NMR (DMSO- d 6 ) δ 0.80 (t, J=4.0 Hz, 3H), 1.19 (t, J=4.0 Hz, 3H), 1.28 (m, 2H), 1.56 (m, 2H), 2.65 (t, J=4.0 Hz, 2H ), 4.10 (q, J = 4.0 Hz, 2H), 5.49 (s, 2H), 6.31 (d, J = 12.0 Hz, 1H), 7.08 (d, J = 7.0 Hz, 2H), 7.38 (d, J = 12.0 Hz, 1H), 7.70 (s, 1H), 7.94 (d, J = 7.0 Hz, 2H), 13.07 (b, 1H); 13 C NMR (DMSO- d 6 ) δ 14.1, 14.6, 22.1, 26.4, 29.7, 46.3, 60.3, 114.7, 126.3, 128.6, 130.3, 130.5, 130.9, 131...

Embodiment 2

[0022] Synthesis of (E)-4-[[2-butyl-5-(2-ethoxycarbonylvinyl)imidazol-1-yl]methyl]benzoic acid [impurity EP12A]:

[0023] To a 500 mL three-neck flask, add 28.6g (0.10 mol) 4-[[(2-butyl-5-formyl) imidazol-1-yl] methyl] benzoic acid, 26.4g (0.20 mol) Monoethyl malonate, a mixed solvent of 75g toluene and 75g xylene, 1.74g (0.02 mol) morpholine, started stirring, raised the temperature to reflux, separated water, and reacted for 12h. The reaction solution was concentrated under reduced pressure, and then purified by column chromatography to obtain 30.3 g of white solid, HPLC purity: 98%, yield: 85.0%. 1 H NMR (DMSO- d 6 ) δ 0.80 (t, J=4.0 Hz, 3H), 1.19 (t, J=4.0 Hz, 3H), 1.28 (m, 2H), 1.56 (m, 2H), 2.65 (t, J=4.0 Hz, 2H ), 4.10 (q, J = 4.0 Hz, 2H), 5.49 (s, 2H), 6.31 (d, J = 12.0 Hz, 1H), 7.08 (d, J = 7.0 Hz, 2H), 7.38 (d, J = 12.0 Hz, 1H), 7.70 (s, 1H), 7.94 (d, J = 7.0 Hz, 2H), 13.07 (b, 1H); 13 C NMR (DMSO- d 6 ) δ 14.1, 14.6, 22.1, 26.4, 29.7, 46.3, 60.3, 114.7, 126.3...

Embodiment 3

[0025] Synthesis of (E)-4-[[2-butyl-5-(2-ethoxycarbonylvinyl)imidazol-1-yl]methyl]benzoic acid [impurity EP12A]:

[0026] To a 500 mL three-neck flask, add 28.6g (0.10 mol) 4-[[(2-butyl-5-formyl) imidazol-1-yl] methyl] benzoic acid, 26.4g (0.20 mol) Monoethyl malonate, 180g toluene, 1.74g (0.02 mol) morpholine, started stirring, raised the temperature to reflux, separated water, and reacted for 12h. The reaction solution was concentrated under reduced pressure, and then purified by column chromatography to obtain 31.3 g of white solid, HPLC purity: 97%, yield: 88.0%. 1 H NMR (DMSO- d 6 ) δ 0.80 (t, J=4.0 Hz, 3H), 1.19 (t, J=4.0 Hz, 3H), 1.28 (m, 2H), 1.56 (m, 2H), 2.65 (t, J=4.0 Hz, 2H ), 4.10 (q, J = 4.0 Hz, 2H), 5.49 (s, 2H), 6.31 (d, J = 12.0 Hz, 1H), 7.08 (d, J = 7.0 Hz, 2H), 7.38 (d, J = 12.0 Hz, 1H), 7.70 (s, 1H), 7.94 (d, J = 7.0 Hz, 2H), 13.07 (b, 1H); 13 C NMR (DMSO- d 6 ) δ 14.1, 14.6, 22.1, 26.4, 29.7, 46.3, 60.3, 114.7, 126.3, 128.6, 130.3, 130.5, 130.9, 131...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com