Prefabricated concrete steel wire net rack sandwiched curtain wall and installation method thereof

A prefabricated concrete, steel wire mesh frame technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of limited effects such as earthquake resistance, thermal insulation, heat insulation, etc., save transportation and installation costs, facilitate transportation and installation, and carry capacity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

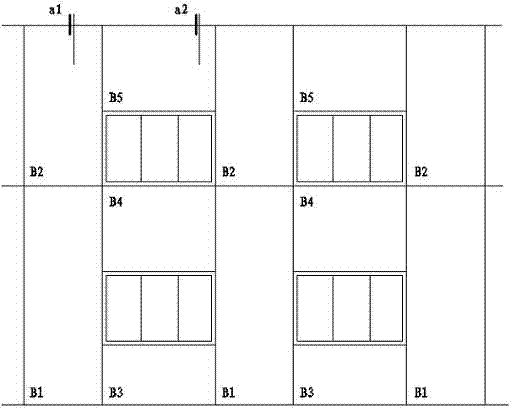

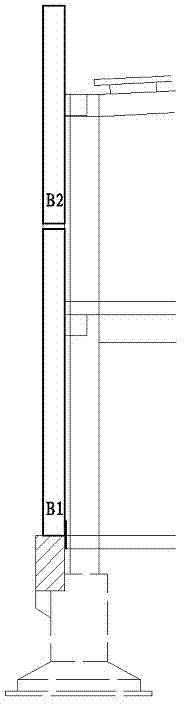

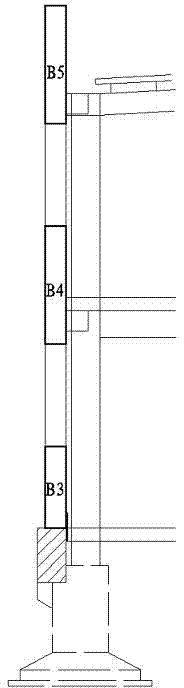

[0039] The invention provides a prefabricated concrete steel wire grid sandwich curtain wall, such as Figure 1-12 As shown, the slatted assembly structure is adopted, and the slats include the upper window panel (used for the parapet on the top floor of the building) B5, the lower window panels B3, B4 and the window panels B1, B2. The curtain wall is assembled in the form of strips, which is beneficial to reduce the shape and specifications of the panels, promote the standardization, finalization and industrial production of parts, reduce costs and improve quality.

[0040] The slats are sequentially provided with an inner concrete layer (also called an inner leaf wall) 1, an insulation layer (polystyrene board) 2 and an outer concrete layer (also called an outer leaf wall) 3 from the inner side to the outer side, and the curtain wall The concrete thickness of the outer leaf wall is 50mm, the thickness of the inner leaf wall is 60mm, and the thickness of the sandwich polystyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com