Plastic flange connecting sealing system

A technology of sealing system and flange, which is applied in the direction of flange connection, pipe/pipe joint/pipe fitting, passing components, etc. It can solve the problems of poor sealing reliability of rubber sealing ring, increase of production cost, high hardness of nylon pipe, etc., and achieve extended use Longer life, improved construction safety, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

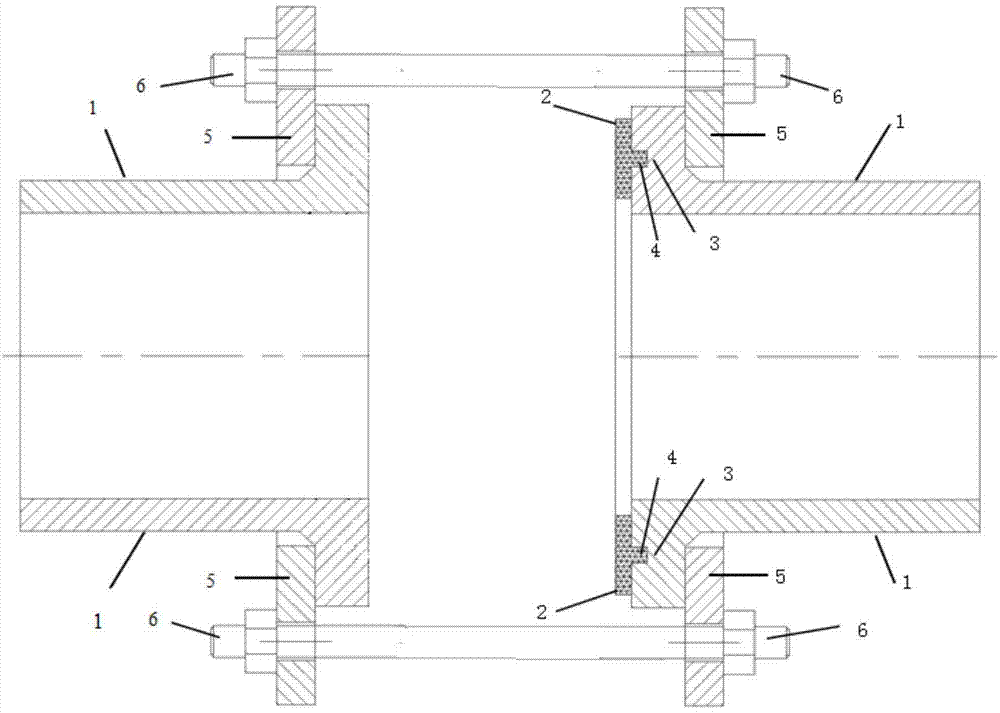

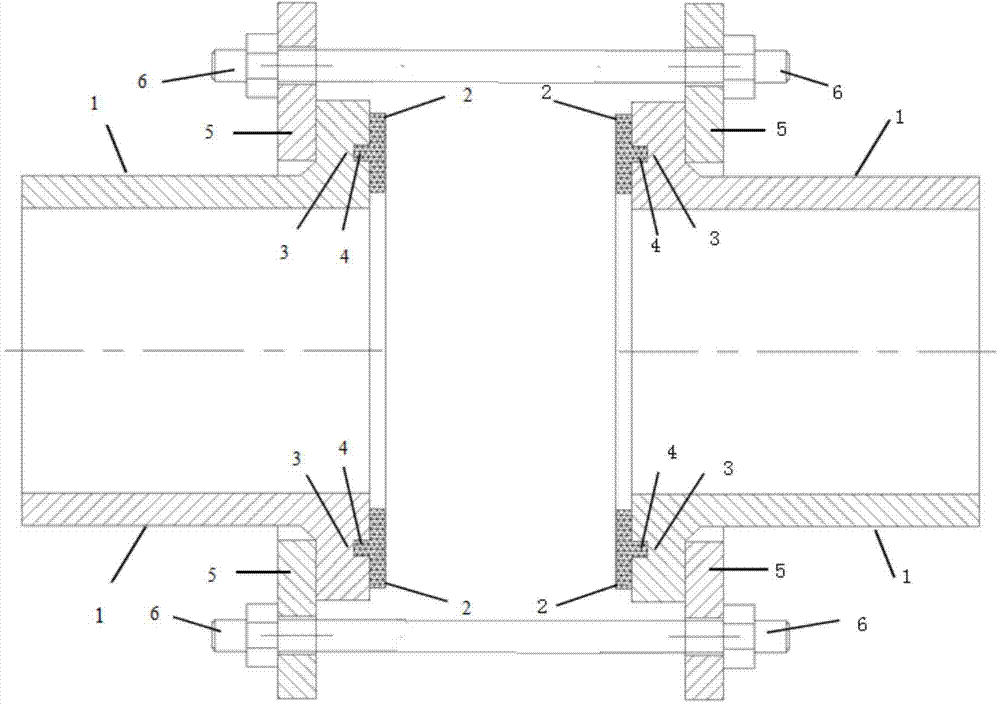

[0026] Such as Figure 1-2 shown.

[0027] A plastic flange connection sealing system, including a flange pipe fitting part and a sealing ring 2; the radial section of the sealing ring 2 is "T" shaped; the flange pipe fitting part includes two flange pipe heads 1; the The connecting surface of the flange pipe head 1 is provided with an annular groove 3 coaxial with the flange pipe head 1; one side of the sealing ring 2 is provided with an annular protrusion 4 coaxial with the sealing ring 2; The annular protrusion 4 is embedded in the annular groove 3; the two flanged pipe heads 1 are tightly and fixedly connected by bolts; the width of the annular protrusion 4 is 1 / 4 of the width of the sealing ring 2 , the height of the annular protrusion 4 is 1 / 3 of the thickness of the sealing ring 2; the radial sections of the annular protrusion 4 and the annular groove 3 are rectangular, and the width of the annular protrusion 4 is smaller than the The width of the annular groove 3 is ...

Embodiment 2

[0029] A plastic flange connection sealing system as described in Embodiment 1, the difference is that: the flange head 1 is sleeved with a metal flange 5, and the two flange head 1 are matched with the The metal flange 5 is fixedly connected. The metal flange 5 is used for connection, and there is no need to install a connecting plate on the pipe fitting itself. The manufacture of the pipe fitting is simple, resources and procedures are saved, and production and connection efficiency are improved.

Embodiment 3

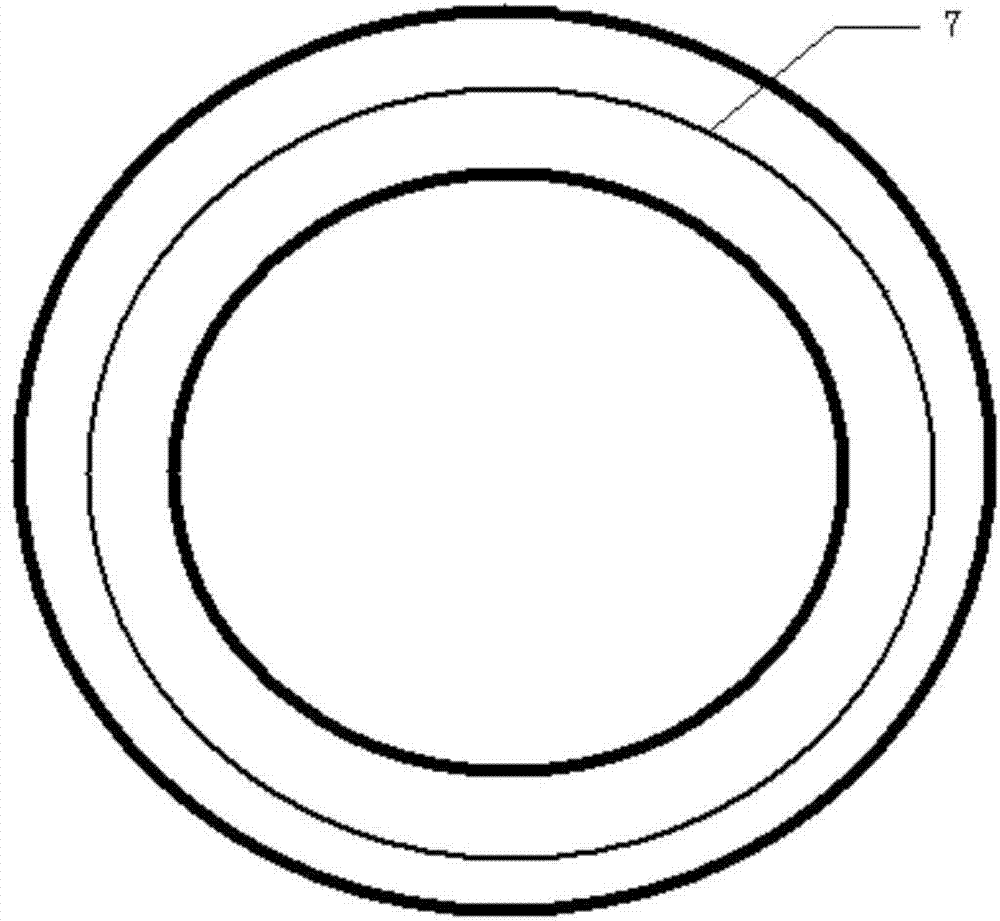

[0031] A plastic flange connection sealing system as described in Embodiment 1, the difference is that: the side of the sealing ring 2 opposite to the annular protrusion 4 is provided with a small annular protrusion 7 coaxial with the sealing ring 2 , the height of the small annular protrusion is 5mm; the number of the small annular protrusions is 5. The small annular protrusion 7 improves the contact surface between the gaskets and the friction force between the contact surfaces, which can improve the sealing and stability of the flange connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com