Reflecting material bead-planting substrate

A reflective material and bead-planting technology, which is applied in optics, optical components, instruments, etc., can solve the problems of easy peeling, low softening point, and impossibility of bead-planting substrates, etc., and achieve the effect of small adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

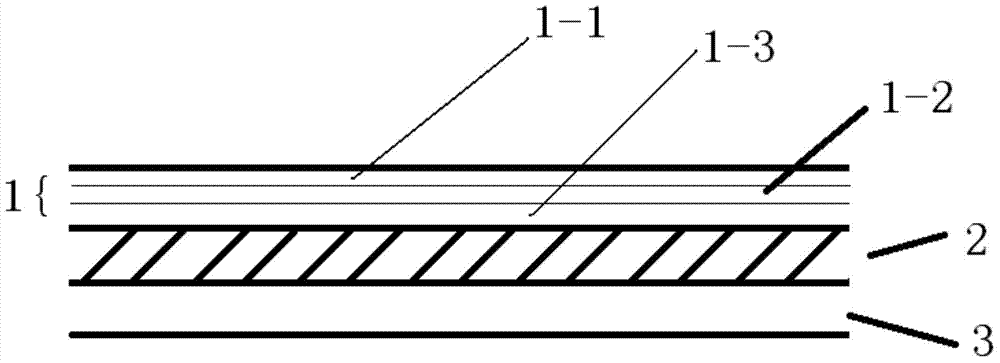

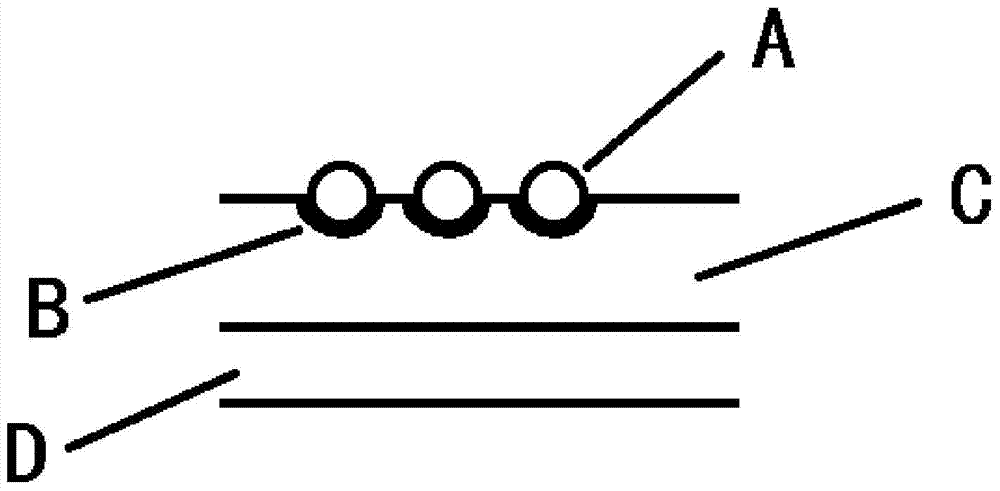

[0042] A reflective material bead-planted base material, the structure of which is as follows figure 1 As shown, the reflective material beaded base material includes a beaded PE film layer 1, a glue layer 2 and a PET film layer 3, and the beaded PE film layer is composed of an outer layer 1-3, a middle layer 1-2 and an inner layer 1-1 is composed of three layers, and the surface of the outer layer is bonded with the PET film layer through the glue layer. The raw material ratio of the outer layer, middle layer and inner layer is shown in Table 1, Table 2 and Table 3.

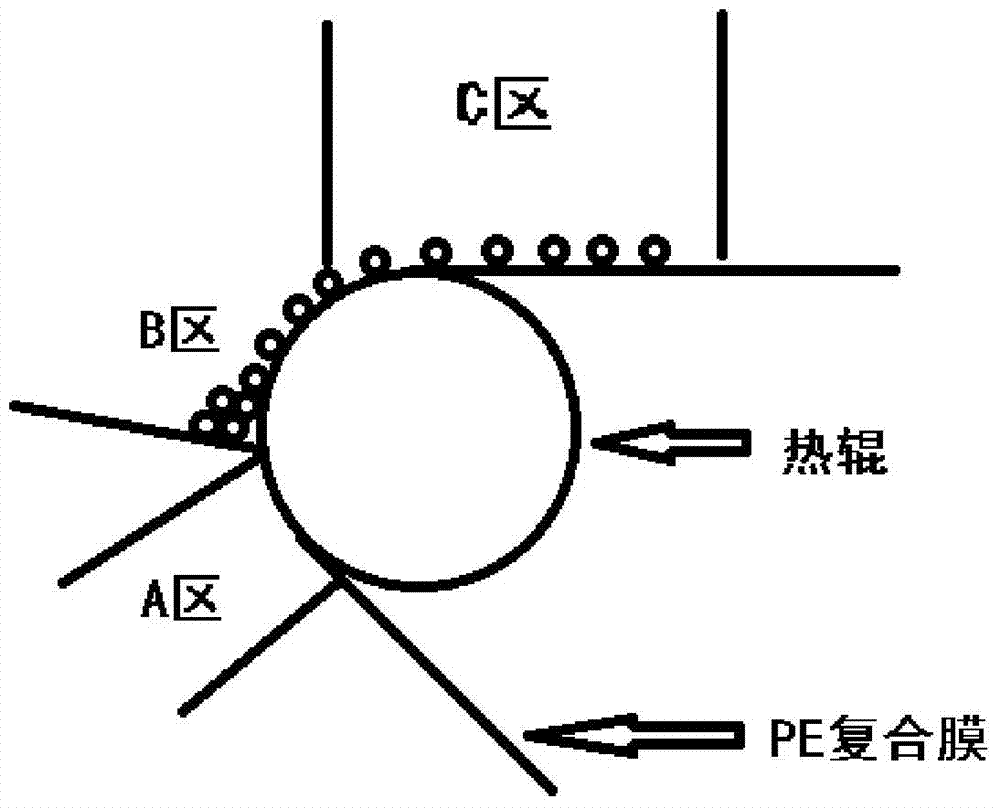

[0043] The present invention finally adopts the method of blow molding to produce the bead-embedded PE layer of the reflective material bead-planting base material, and then compound processing with the high-temperature-resistant PET film to make the finished bead-planting base material such as Figure 4 .

[0044] The equipment adopts a crystal point-free film blowing machine with a screw diameter of 65mm and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com