Optical element

An optical element, optical alignment technology, applied in the direction of optical elements, optics, polarizing elements, etc., can solve the problems of uneven optical characteristics, complex power supply system structure, difficult to achieve visual sensitivity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] After drying, the thickness of the composition reaches about A composition for forming an optical alignment film was coated on one surface of the glass by means of a method, followed by drying in an oven at 80° C. for 2 minutes. The composition prepared by dissolving 5-norbornene-2-methylcinnamate (purchased from LG Chem Ltd.) in toluene solvent so that the concentration of the solids becomes 2 wt % was used as above for forming optical The composition of the alignment film.

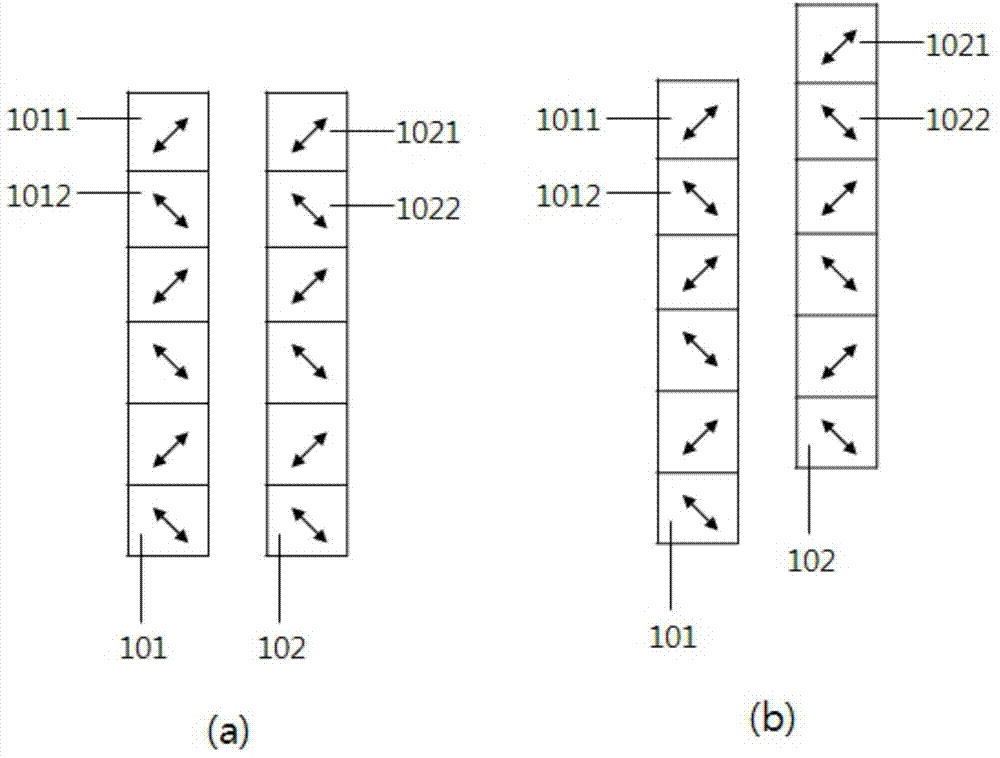

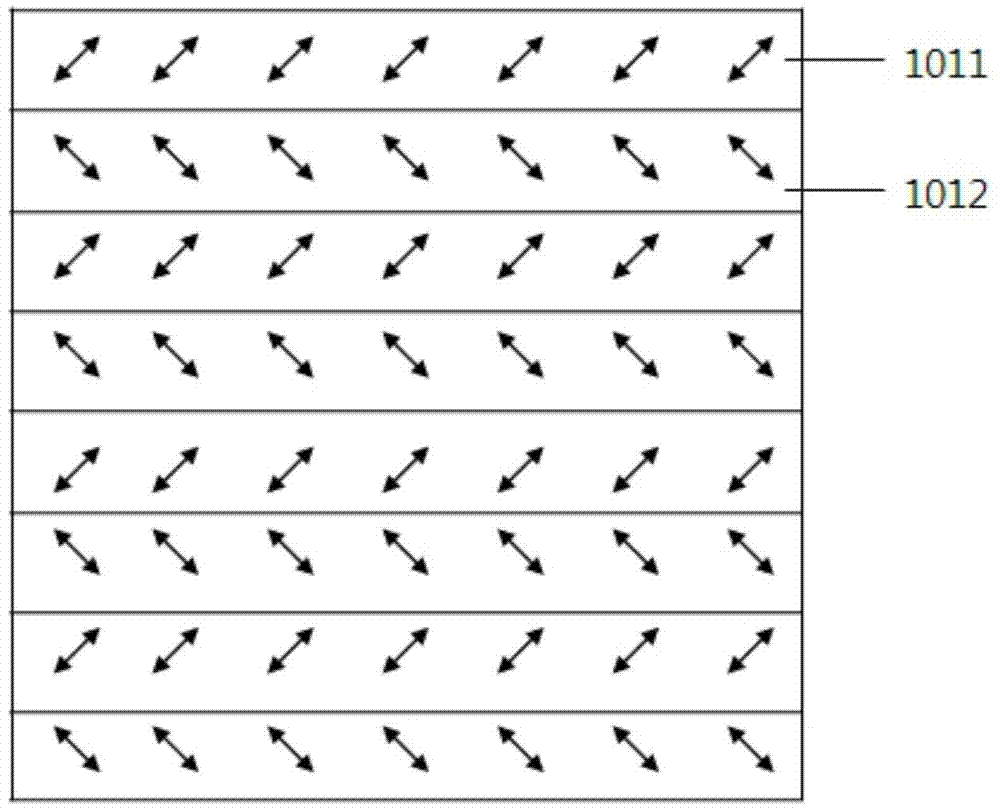

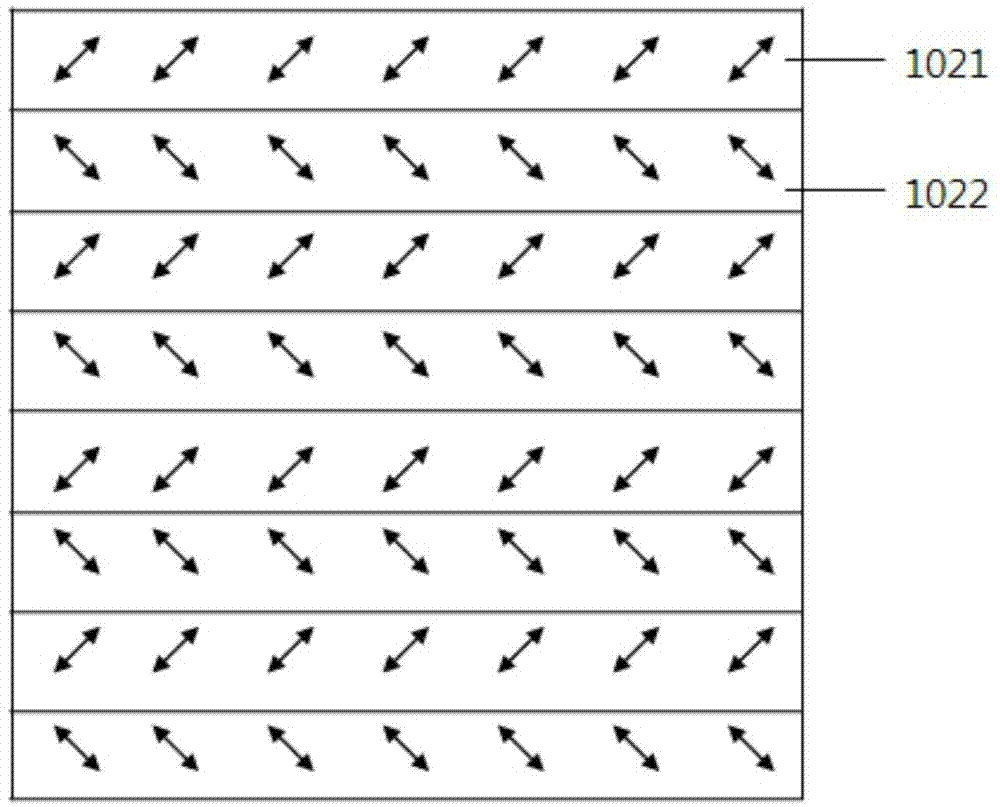

[0074] Next, according to the method disclosed in Korean Patent Application No. 2010-0009723, the dried composition for forming an optical alignment film is aligned to form an optical alignment film comprising a first alignment region and a second alignment region aligned in different directions. Alignment film. Specifically, a pattern mask in which light-transmitting portions and light-blocking portions in a stripe shape (having a width of about 450 μm) were alternately formed in the vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com