Multifunctional automatic transplanter

A transplanting machine and multi-functional technology, applied in the field of agricultural equipment, can solve the problems of time-consuming and laborious, large differences in transplanting quality, low work efficiency, etc., and achieve the effect of improving the planting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

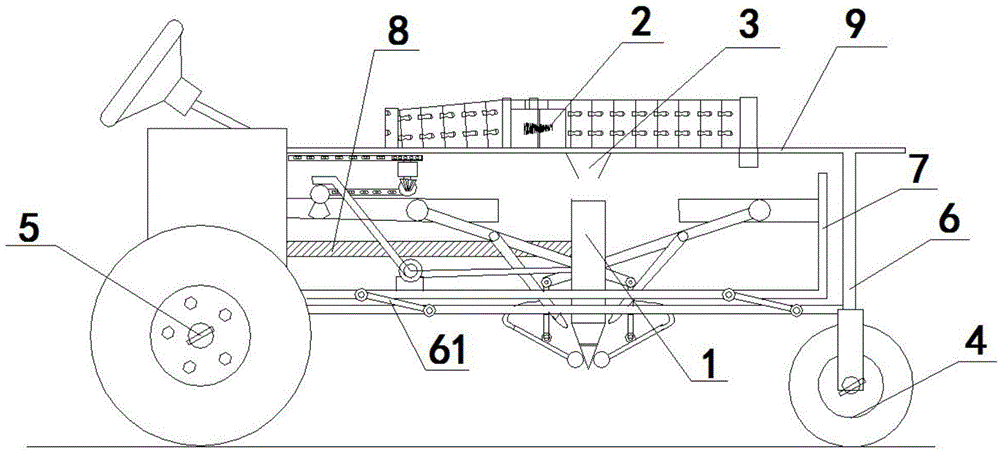

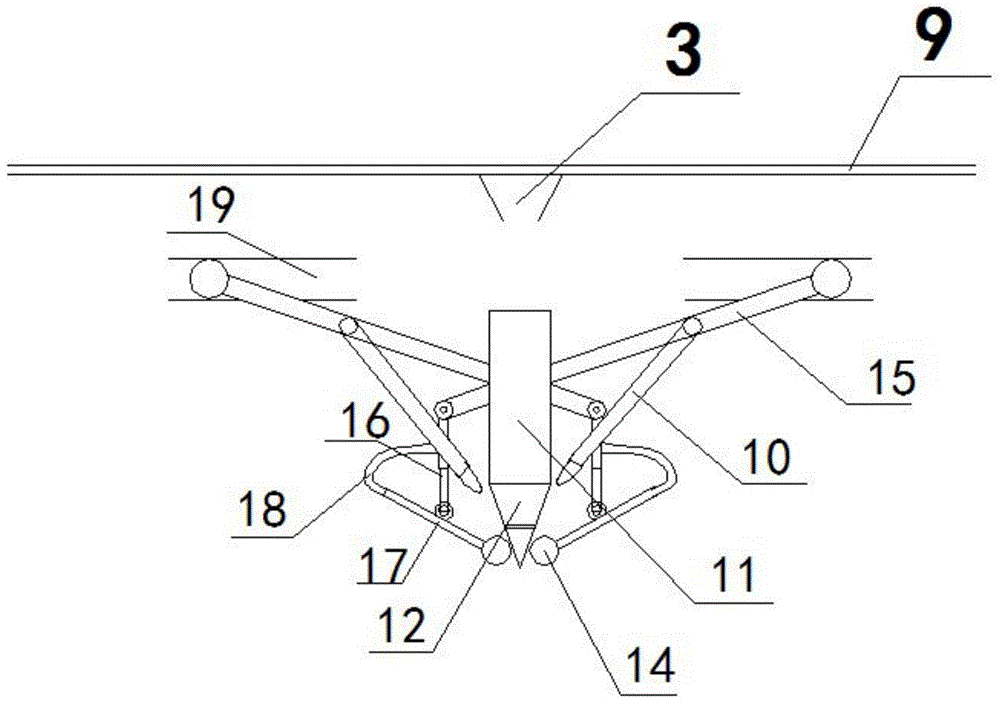

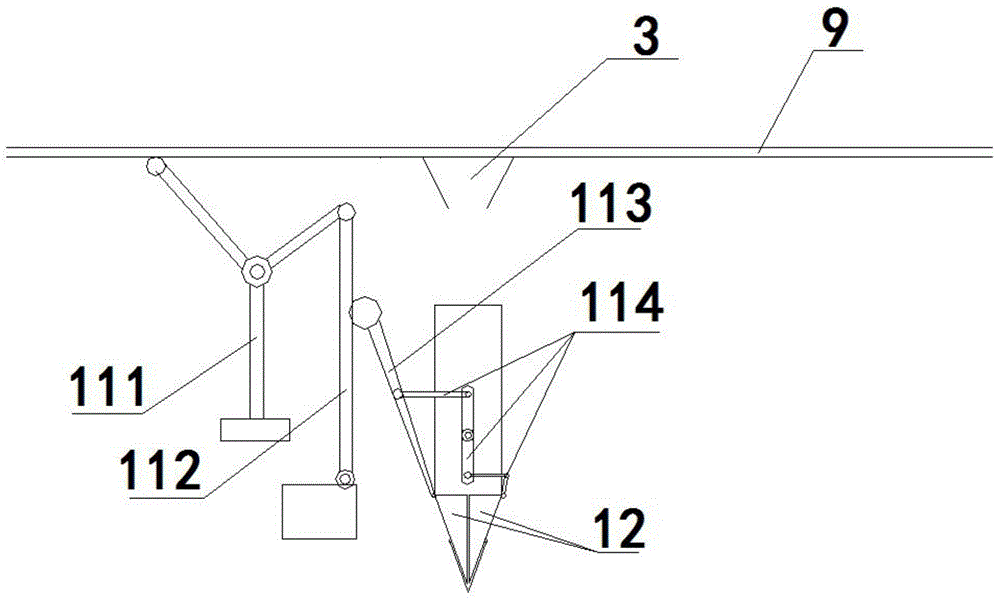

[0030] like figure 1 As shown, the present invention provides a kind of multifunctional automatic transplanting machine, comprising: frame, seedling planting device 1 and workbench 9, driven guide wheel 4 is installed on the front portion of frame, and the rear portion of frame is installed with Drive wheel 5, seedling planting device 1 is arranged on the middle part of frame, is specifically arranged between guide wheel and drive wheel 5, but the working trajectory of seedling planting device 1 and guide wheel or drive wheel 5 are not on the same straight line, workbench 9 Installed on the top of the frame, the workbench 9 is provided with a seedling drop hole 3 matched with the seedling planting device 1, and the seedlings that can be screened by the workbench 9 are dropped into the seedling planting device 1 by the seedling drop hole 3 and planted.

[0031]Frame among the present invention comprises first frame 6 and second frame 7, as figure 1 Shown, the first frame 6 is ...

no. 2 example

[0038] On the basis of the first embodiment as Image 6 As shown, in order to prevent the seedling pulling device 23 from damaging the seedlings due to its mechanical movement during the work, the seedling pulling device 23 is designed as two parts, the seedling pulling shaft 231 and the seedling pulling sheet 232, at the front end of the seedling pulling sheet 232 A buffer plectrum 235 is provided, and when the seedling-pickling shaft 231 drives the plectrum-pickling piece 232 to swing, the plectrum-pickling piece 232 directly connected to the rotating shaft moves the plectrum plectrum 235 to work, so that the plectrum plectrum 235 is directly in contact with the seedlings. This can prevent hard contact between the seedling picking piece 232 and the seedlings, and damage the seedlings. The seedling picking piece 232 and the buffer picking piece 235 are connected by the hinge shaft 233. and the buffer paddle 235 are set as Image 6 Shrapnel shown. like Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com