Crusher for detecting sample leather and braided fabrics

A technology for detecting samples and woven fabrics, applied in grain processing and other directions, can solve problems such as inability to effectively pulverize leather, and achieve the effect of convenient operation and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

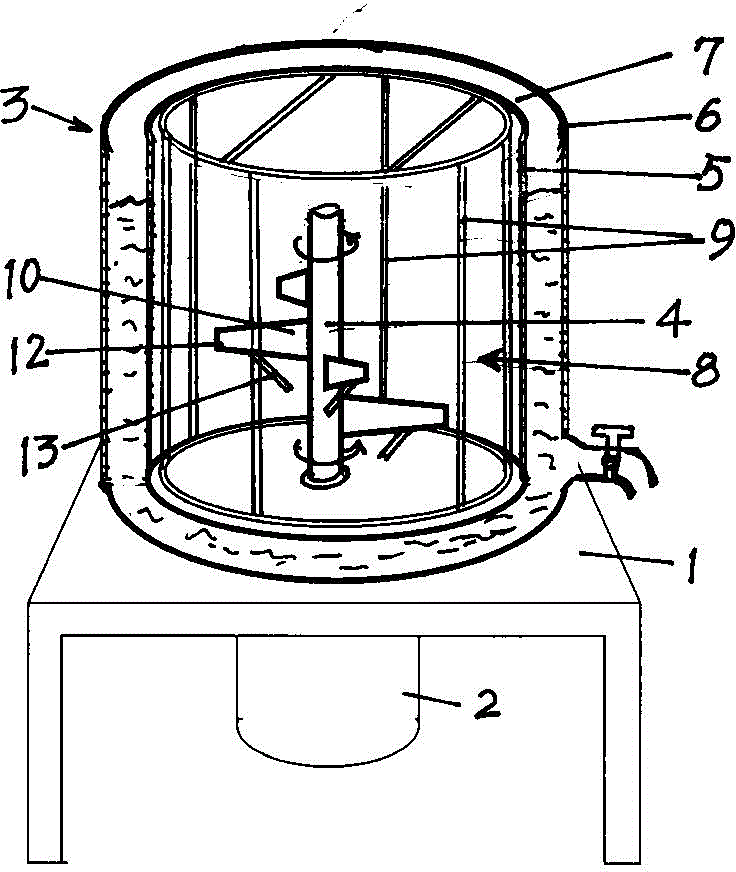

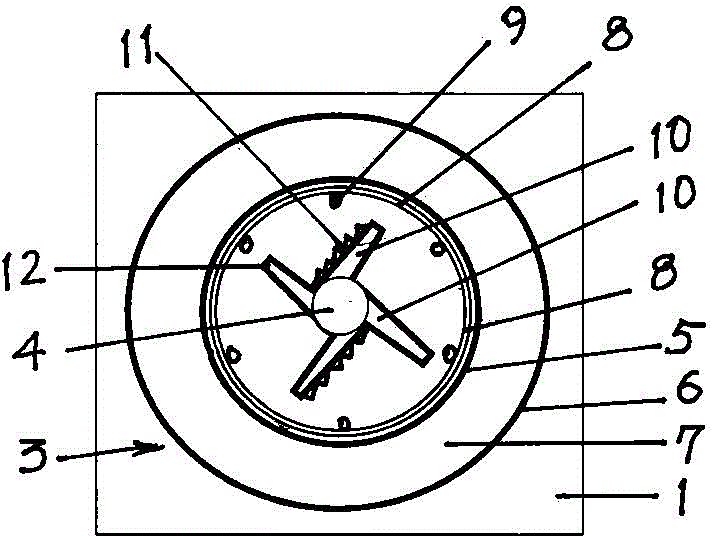

[0018] Embodiment 1, for testing the pulverizer of sample leather

[0019] like figure 1 , 2 , comprising a frame panel 1, a motor 2 is arranged below the frame panel 1, a crushing cylinder 3 is arranged above the frame panel 1, the rotating shaft of the motor 2 is rotationally connected with the central rotating shaft 4 of the crushing cylinder 3; the crushing cylinder 3 is divided into circular The inner cylinder 5 and the outer cylinder 6, the interlayer container space 7 between the inner cylinder 5 and the outer cylinder 6; the inner cylinder 5 is placed with a circular frame-type squirrel cage 8, and the center of the inner cylinder 5 is provided with a central rotating shaft 4 and a frame-type squirrel cage 8 Three vertical bars 9 are established at least, and the vertical bars 9 and the central rotating shaft 4 are all arranged vertically; a plurality of blades 10 are arranged at different height positions of the central rotating shaft 4 .

[0020] Among the pluralit...

Embodiment 2

[0021] Embodiment 2, pulverizer for testing sample braid

[0022] like figure 1 , 2 , as the whole structure of embodiment 1, and,

[0023] One end of the blade 10 is connected with the central rotating shaft 4, and one end of the blade 10 is a free end 12, and an oblique rod 13 is arranged on the knife back of the free end 12 of the blade 10, and the included angle between the blade 10 and the oblique rod 13 is 20 to 60 degrees. .

[0024] The cross section between the edge and the back of the blade 10 is shallow concave.

[0025] The diameter of the free end of the slanting rod 13 is smaller than the diameter of the connecting end of the slanting rod 13 and the blade 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com