Servo control system and control method for numerically controlled drilling machine tool

A servo control system and machine tool technology, applied in thread trimmers, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of low production efficiency, waste of manual tap removal, and increased tapping torque, etc., to achieve convenient centralized control, improve Convenience and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

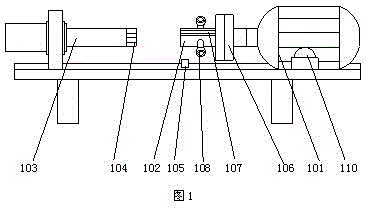

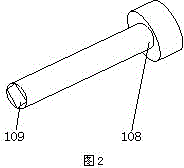

[0025] Such as figure 1 , 2 As shown, a servo control system for a numerically controlled drilling machine tool includes a servo motor 101 and a workpiece fixture 102 arranged on the servo motor 101. The servo motor 101 is respectively provided with a start button and a stop button, and the servo motor 101 passes The line is electrically connected to the control panel, and a hydraulic cylinder 103 is arranged on the opposite side of the servo motor 101. The axis of the hydraulic cylinder 103 is on the same straight line as the axis of the workpiece fixture 102. The opposite end is provided with a tap fixture 104, and a proximity switch 105 is arranged below the tap fixture 104. The proximity switch 105 is electrically connected to the control panel, and the rotational speed sensor is connected to the control panel through a line. A torque sensor is arranged on the top, and the torque sensor is connected to the control panel through a line. A cylinder 110 is arranged on one si...

Embodiment 2

[0032] The present invention also discloses a control method of a CNC drilling machine tool servo control system, including the following steps:

[0033] S1: Install the workpiece to be processed, and start the tap for tapping: monitor the workpiece speed in real time through the speed sensor, and send the speed information to the control panel for display, use the torque sensor to detect the torque of the workpiece fixture, and send the torque information to control panel;

[0034] S2: The control panel compares the received torque and speed information with the preset information, and sends control information to the servo motor to adjust the speed of the servo motor when the speed and torque exceed the preset range;

[0035] S3: The servo motor receives the information sent by the control panel, and adjusts the speed according to the information sent by the control panel. The torque sensor and the speed sensor detect the adjusted speed of the servo motor and the torque of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com