Card cutting press workblank transferring mechanical arm

A technology for transferring manipulators and punching machines, which is applied in metal processing and other directions, can solve problems such as personnel injury, low efficiency, and uneven placement, and achieve the effects of safe, high-efficiency, and reliable work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

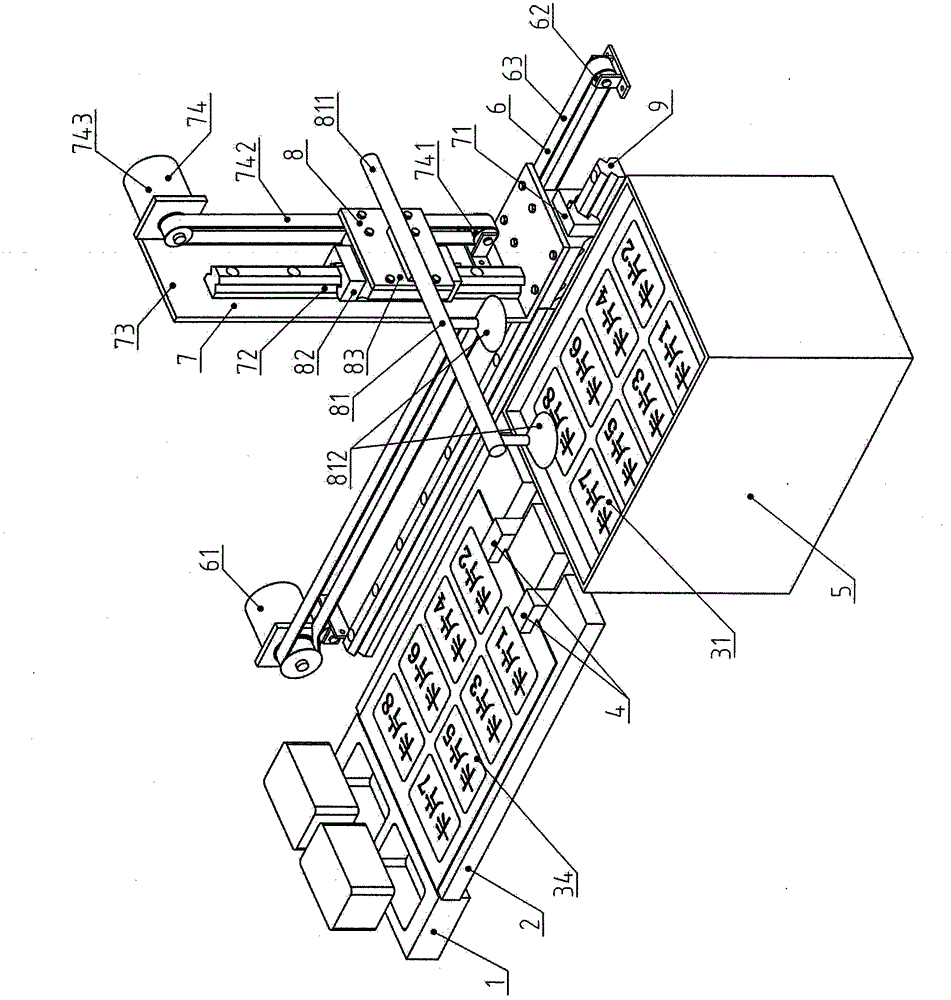

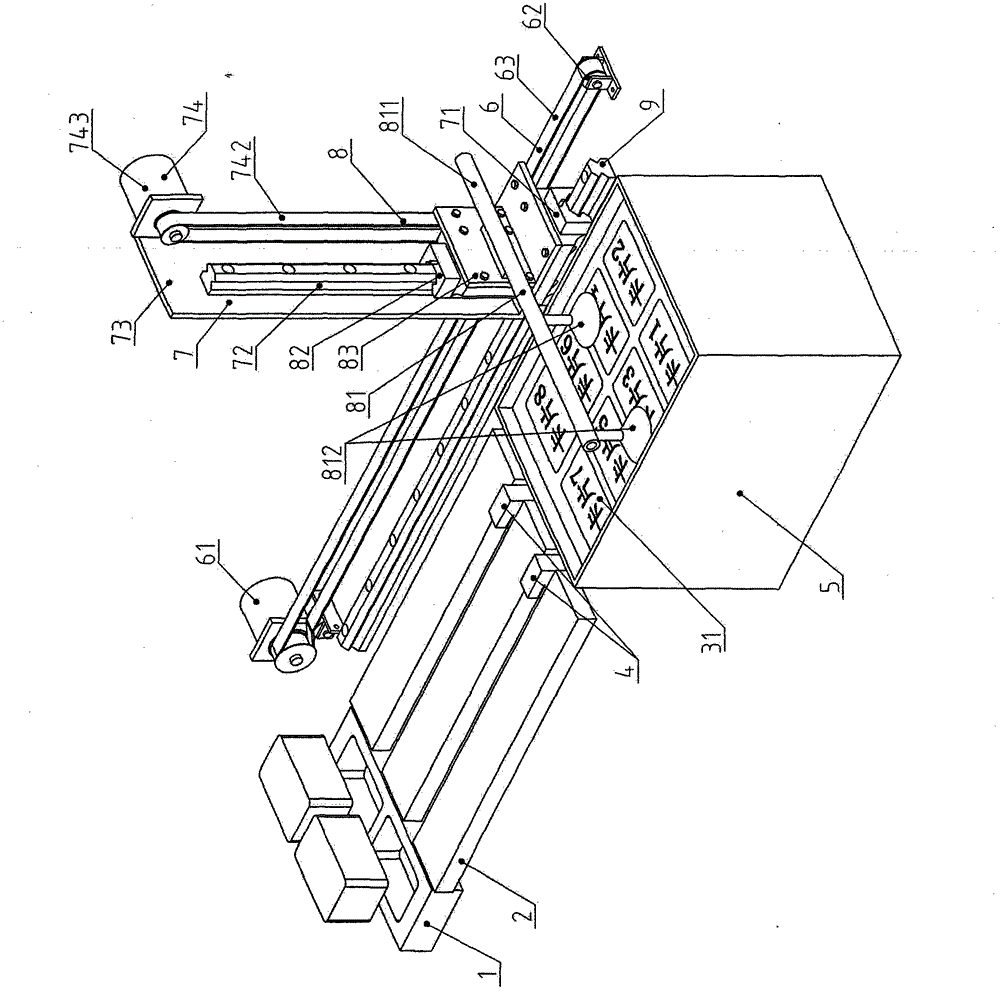

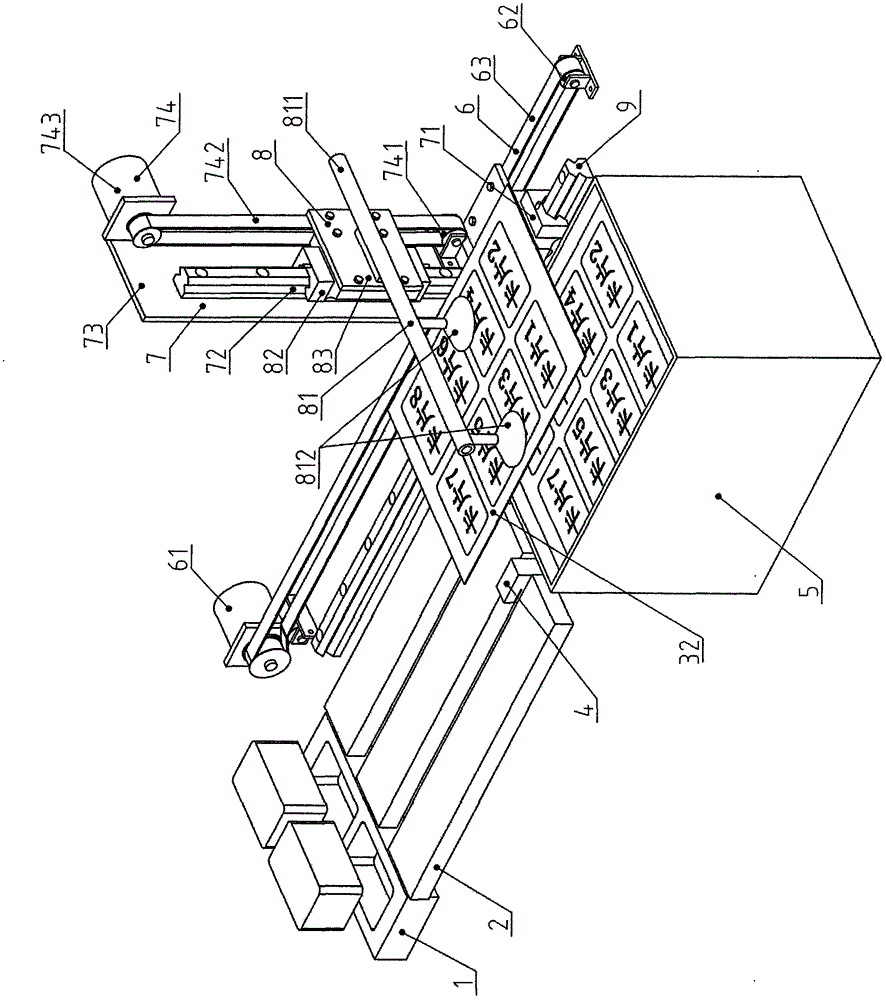

[0024] Example: see Figure 1 to Figure 6 .

[0025] A blank transfer manipulator for a card punching machine, including a material box 5, a horizontal linear guide rail 9, a translation assembly 7, and a lifting assembly 8; the material box 5 is located on the side of the feeding platform 2, and multiple blanks 3 are horizontally stacked inside, as shown in the figure As shown in station 31 in the material box, the upper opening is flush with the upper surface of the feeding platform 2; the horizontal linear guide rail 9 is fixedly connected with the frame; the translation assembly 7 includes a translation slider 71, a translation support 73 and a vertical linear guide rail 72, and the The slide block 71 and the horizontal linear guide rail 9 form a linear guide rail pair, the translation support 73 is fixedly connected with the translation slide block 71, the vertical linear guide rail 72 is fixedly connected with the translation support 73, and the vertical linear guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com