A die-cutting process with asynchronous feeding and seamless splicing

A feeding and asynchronous technology, applied in metal processing and other directions, can solve the problems of material waste and low product yield, and achieve the effects of not easy to damage, reducing material costs, and saving personnel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

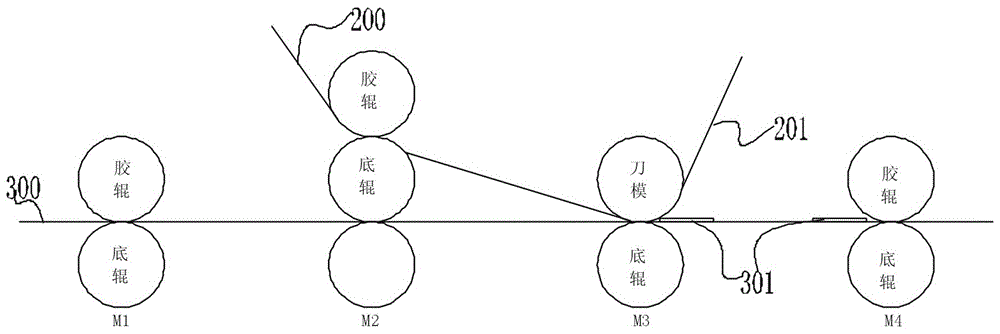

[0020] In the specific implementation of the present invention, the die-cutting process of asynchronous feeding seamless stitching includes the following steps

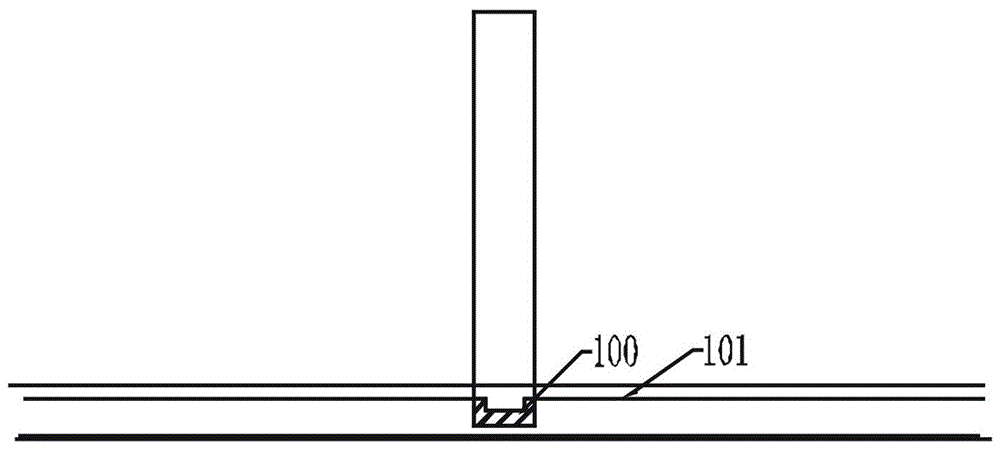

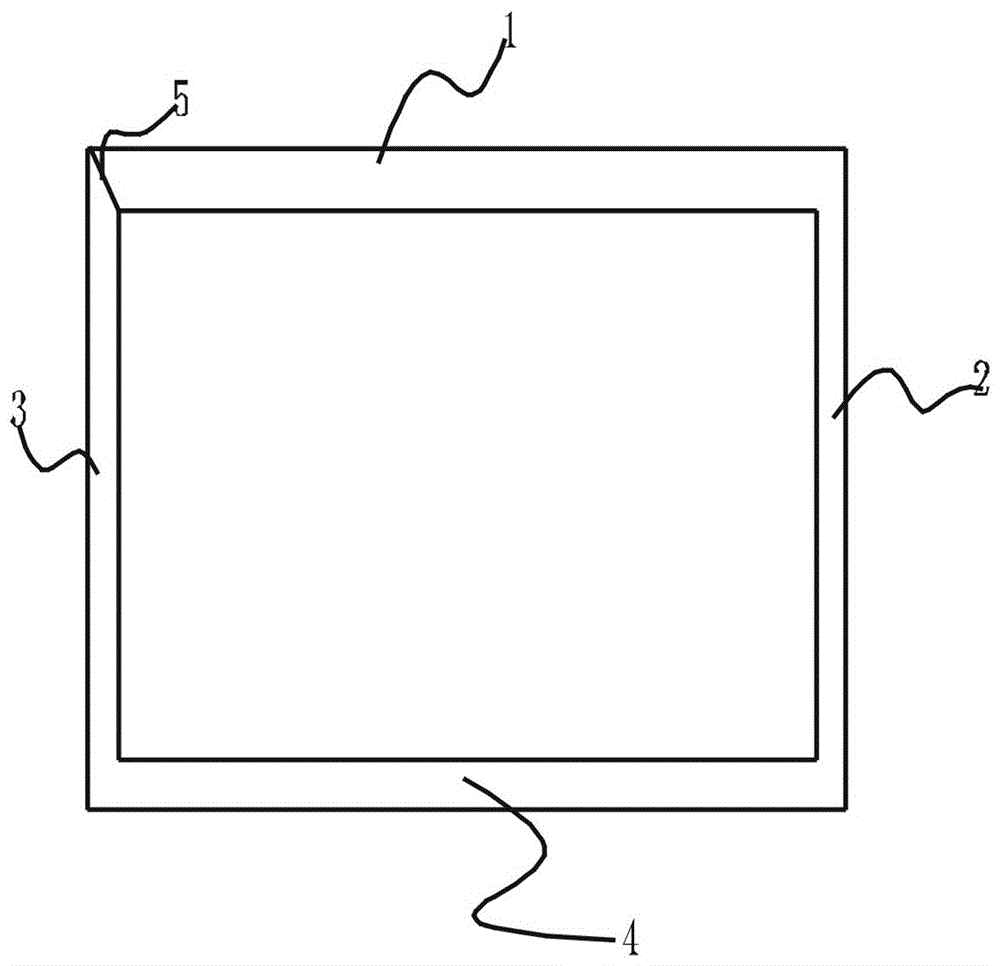

[0021] Cut the four frame strips of a four-frame product first, that is: use asynchronous cutting equipment to cut each frame strip according to the specification of the frame strip on a strip of overall material and reserve a small amount of surplus material; attach the frame strip to the available On the release film that is conveyed and peeled off; the release film with four frame strips is overlapped to form a product frame, and the remaining parts of the four frame strips overlap; a single-piece cutter is used to cut the four frame strips Cut the overlapping part with a single knife; roll to realize the same plane connection of the product frame strips to obtain a complete product; peel off the excess part of the release film. When overlapping and cutting, the order from top to bottom of two adjacent frame strips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com